A hot isostatic pressing method based on additive manufacturing

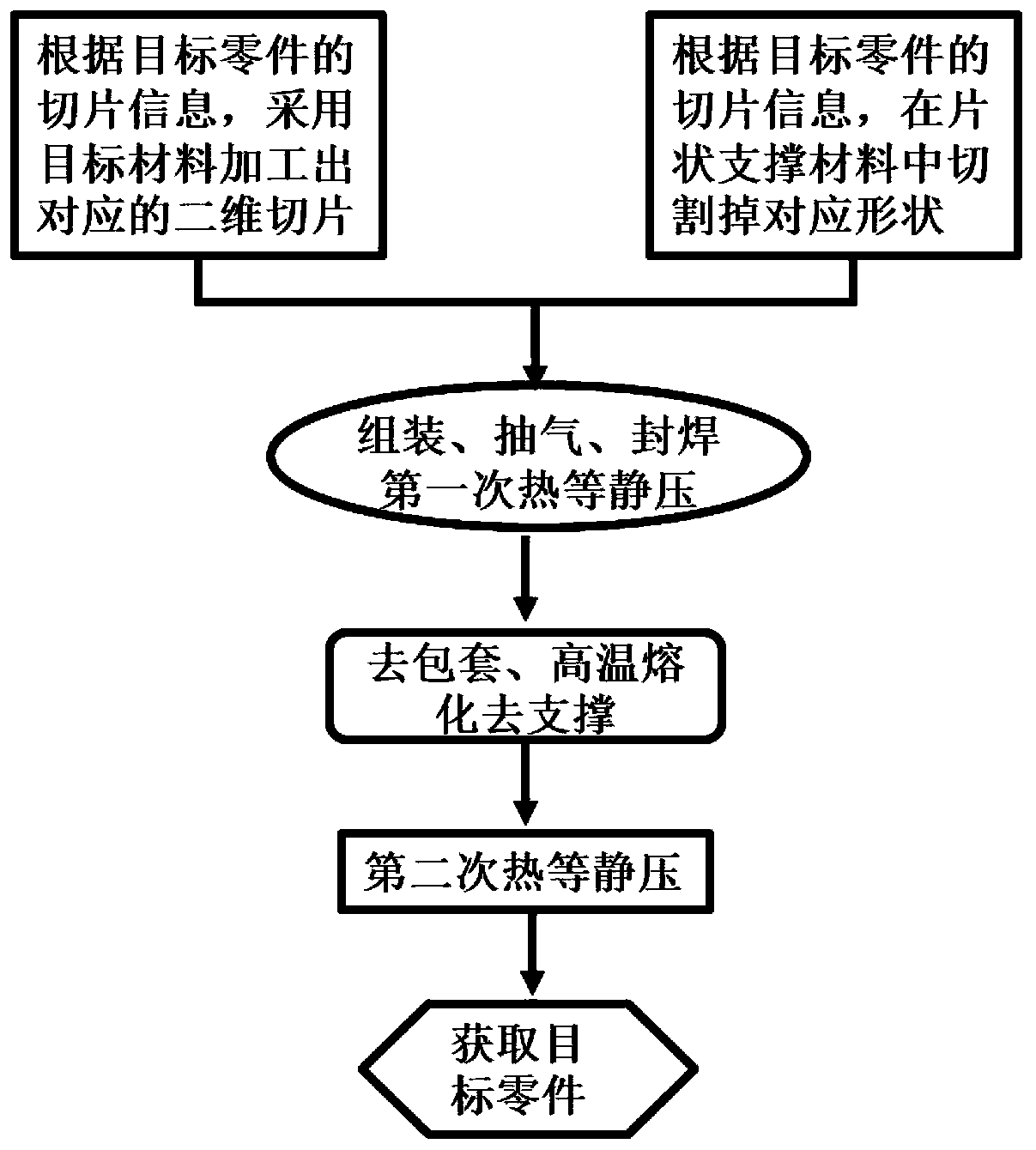

A technology of hot isostatic pressing and additive manufacturing, which is applied in the direction of additive processing, etc., to achieve the effects of controllable forming, support and shape maintenance, and rapid and high-precision forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

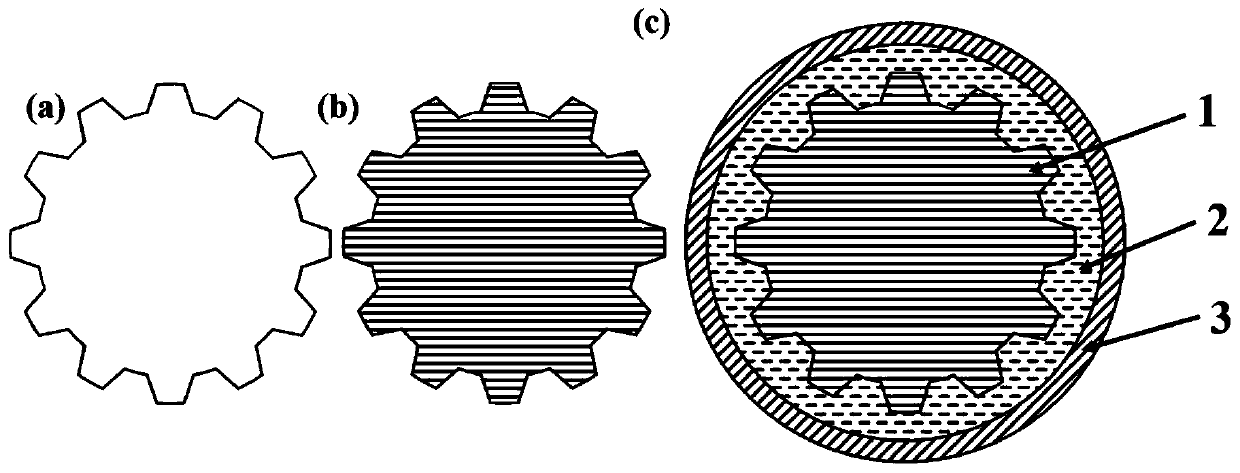

[0049] see figure 2 (a)~(c), the present embodiment utilizes the method for manufacturing the Ti-6Al-4V titanium alloy gear parts of height 100mm, diameter 250mm, among the figure 1 is that solid line represents Ti-6Al-4V titanium alloy slice, 2 The dotted line represents the pure aluminum support material, and 3 is a cylindrical sheath, which specifically includes the following steps:

[0050] 1) According to the 3D CAD model of the titanium alloy gear, the 0.5mm thick slice and the 2D information of the slice are obtained after being processed by the slicing software. -All two-dimensional slices are processed on the 4V titanium alloy plate;

[0051] 2) Select pure aluminum as the support material, and cut out the corresponding slice shape from the pure aluminum sheet support material with a thickness of 0.5mm and a diameter of 280mm according to the slice information of each layer of the target part, where the diameter of the support material is slightly larger than the di...

Embodiment 2

[0061] The product of preparation and process are identical with embodiment 1, just step 5) in vacuum tightness is 10 -4 Pa, in step 6), the temperature and pressure are raised to 600°C and 200MPa at the same time, and the heat preservation and pressure are maintained for 2 hours. 4V titanium alloy gear.

Embodiment 3

[0063] The product of preparation and process are identical with embodiment 1, just step 5) in vacuum tightness is 10 -4 Pa, in step 6), the temperature and pressure are raised to 600°C and 80MPa at the same time, and the heat preservation and pressure are kept for 7 hours. 4V titanium alloy gear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com