Tube grinder hollow shaft R area anti-fatigue performance designing method

A design method and anti-fatigue technology, which can be used in grinding machine parts, machine tools designed for grinding workpiece rotating surfaces, grinding/polishing equipment, etc., can solve problems such as unreasonable structural design of hollow shaft R area, and The effect of avoiding R zone fracture, good fatigue resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

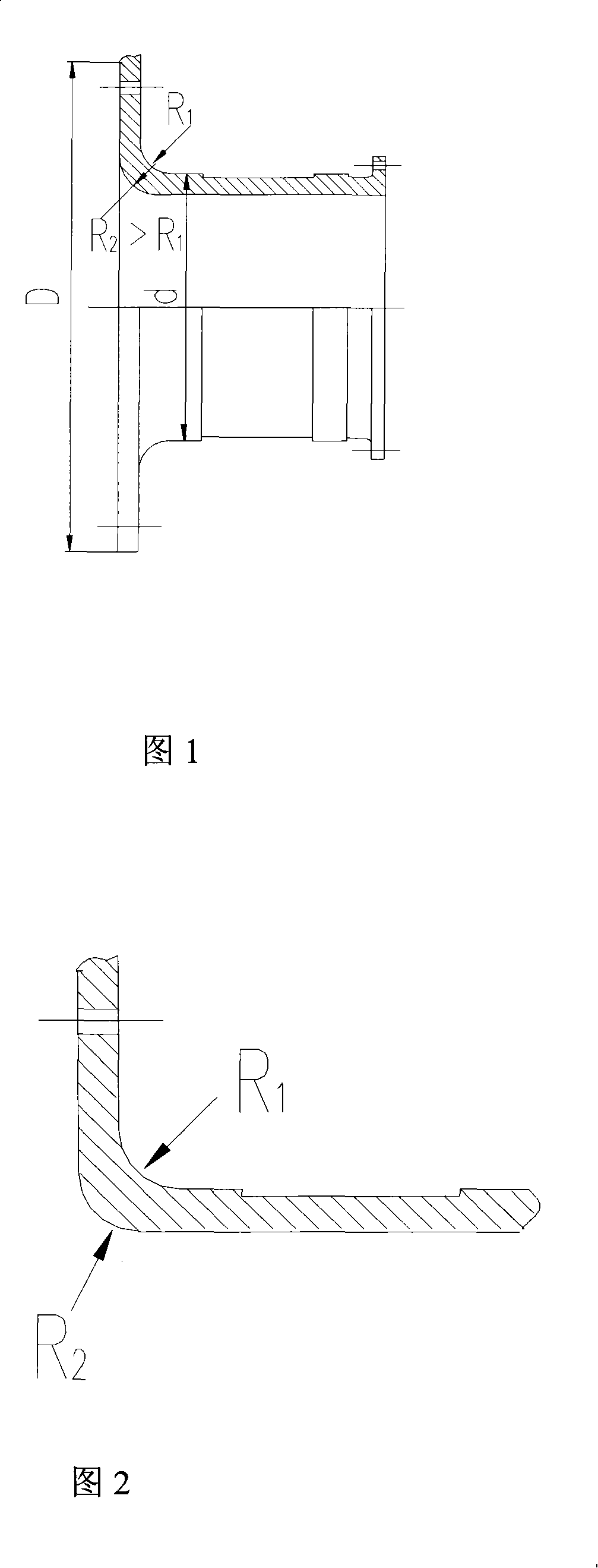

[0012] The design method of the anti-fatigue performance of the hollow shaft R zone of the tube mill of the present invention, wherein the R angle of the hollow shaft R zone is directly related to its stress concentration, that is, the inner circle R of the R zone 1 The larger the angle, the smaller the stress concentration; and the outer circle R of the R area 2 The greater the angle is, the thickness of the R zone becomes thinner. Under the same conditions, Figure 1 rotates along the axis of the hollow shaft compared with Figure 2, and the area of rotation decreases by 23.3-38.5%, which reduces the fatigue strength of the hollow shaft. Therefore, the outer circle R 2 The suitable angle range is: 0.8R 1 ≤R 2 ≤R 1 .

[0013] The durability limit of the hollow shaft material is the direct basis for determining the strength of the hollow shaft under alternating stress. Therefore, improving the durability limit of the hollow shaft is very important for increasing the ability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com