Design of pure static pressure sliding shoe structure for fixed end and free end in tube mill supporting device

A technology of a support device and a design method, which is applied to machine tools designed for grinding the rotating surface of workpieces, large fixed members, grinding/polishing equipment, etc., can solve the problems of short bearing life, high sliding shoe temperature, and complex processing, etc. Achieve the effect of strong load performance, good self-calibration performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

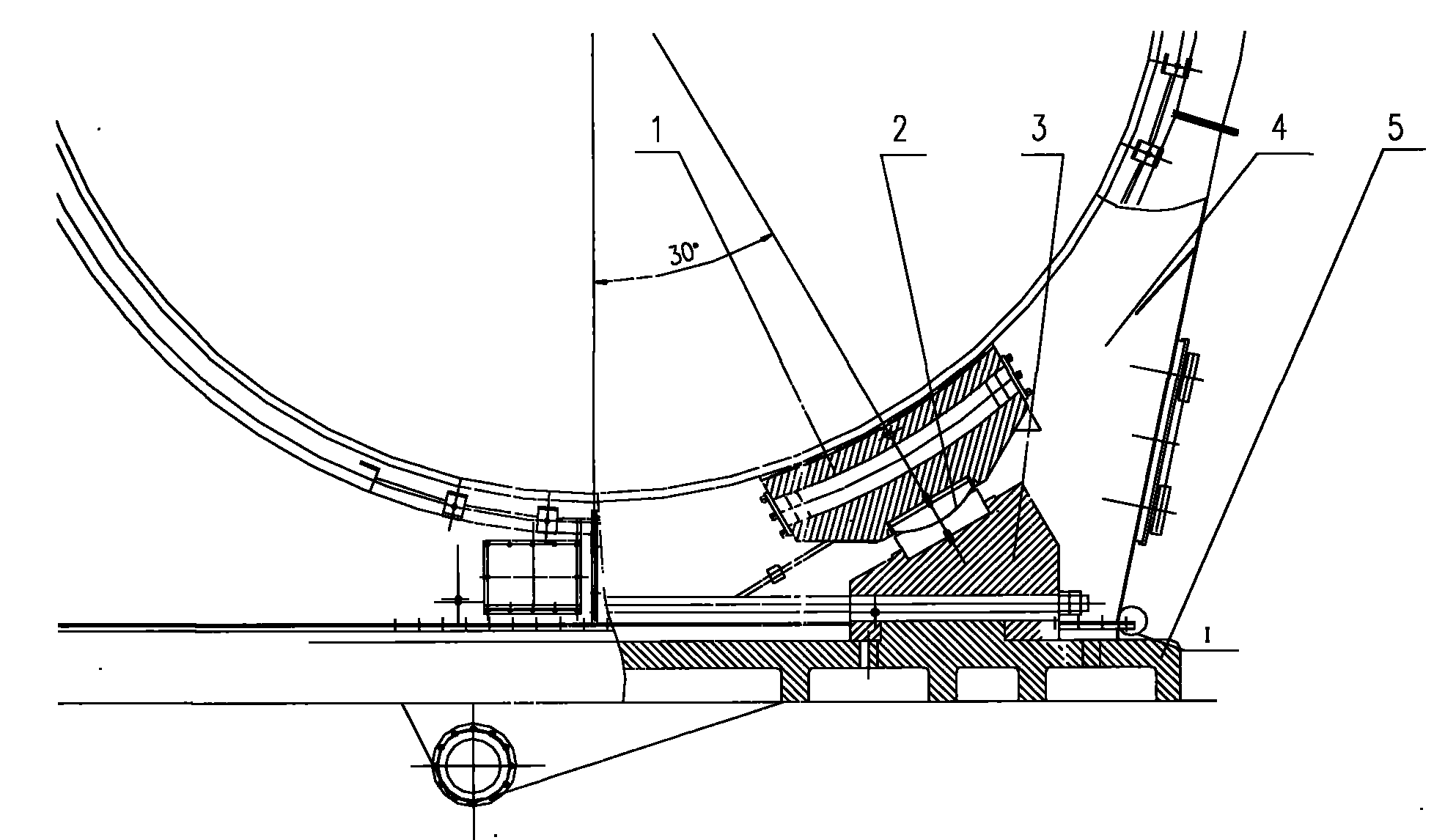

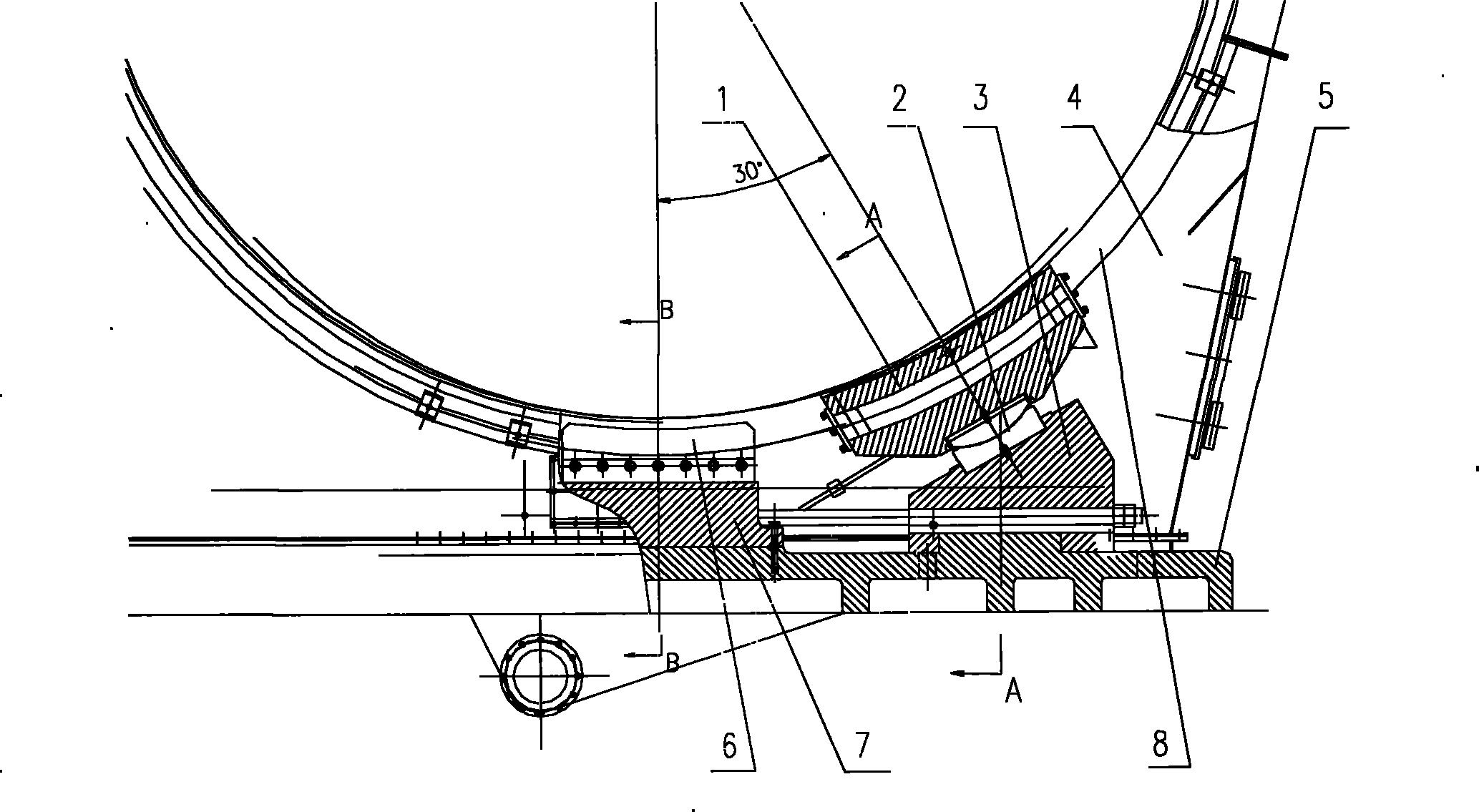

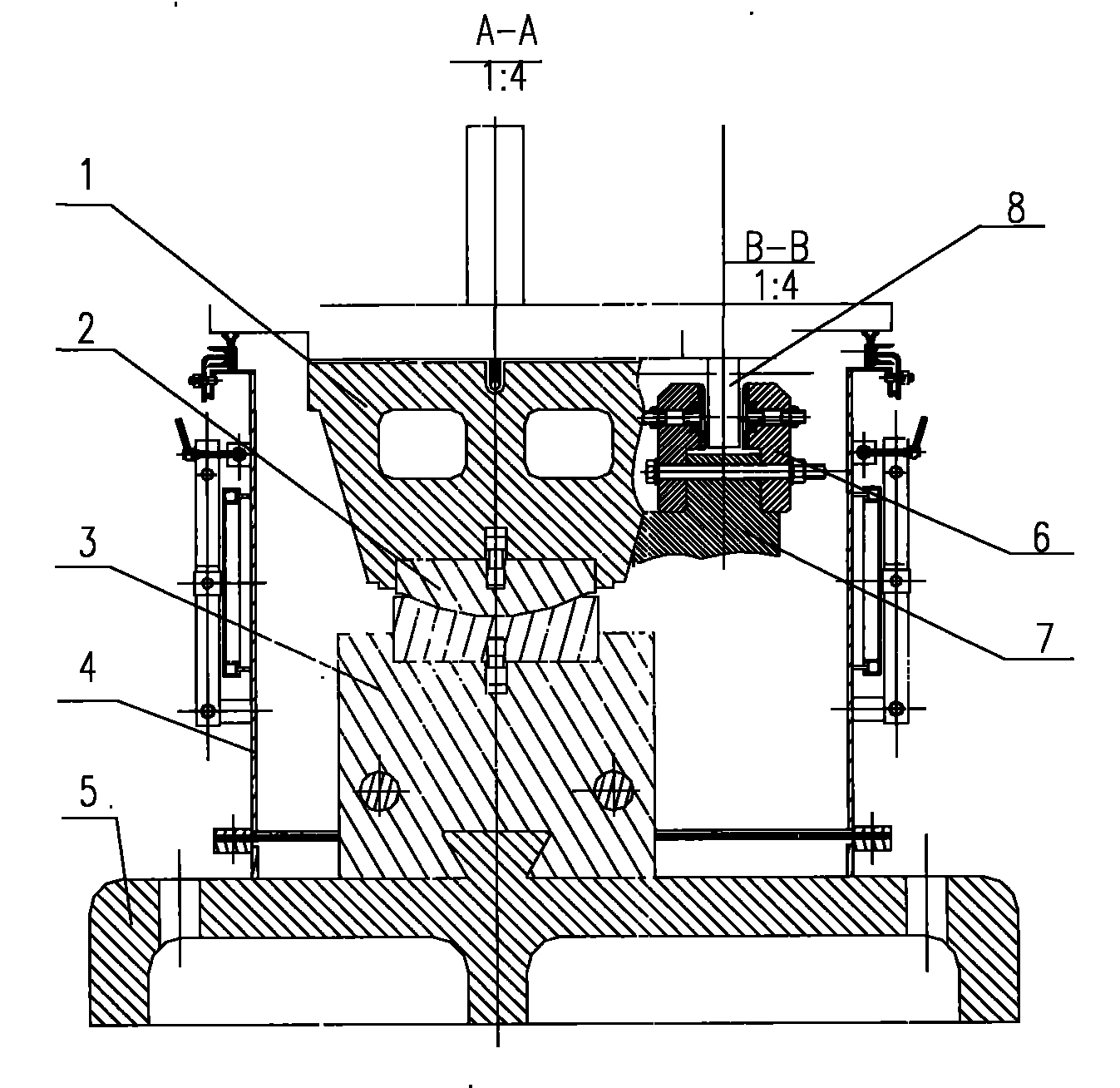

[0025] The design method of the fixed and movable end pure static pressure sliding shoes in the support device of the tube mill of the present invention is to design the movable end in the support device of the tube mill, that is, the feed end, as an axially movable radial pure static pressure sliding shoe structure See figure 1 , the fixed end, that is, the discharge end, is designed as an axial thrust and radially movable axial + radial combination of combined pure static pressure sliding shoe structure see Figure 2-3 .

[0026] combine figure 1 , the design method for the radial pure static pressure sliding shoe structure is as follows: the sliding shoe structure is supported by two supporting tiles 1 at an angle of 30° to the vertical direction at the movable end of the tube mill, and the lower part of each supporting tile 1 is provided with a concave The sphere and the convex sphere 2, the convex sphere is seated in the concave sphere, the two are in spherical contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com