Thickness changing sewing needle rod wire selecting mechanism

A sewing needle and thickness-changing technology, which is applied to the sewing machine thread take-up device, sewing machine components, sewing equipment, etc., can solve the problems of large needle stroke, poor stitch quality, and high labor intensity, and achieve moderate and balanced sewing thread tension. Appropriate tightness, neat and beautiful stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

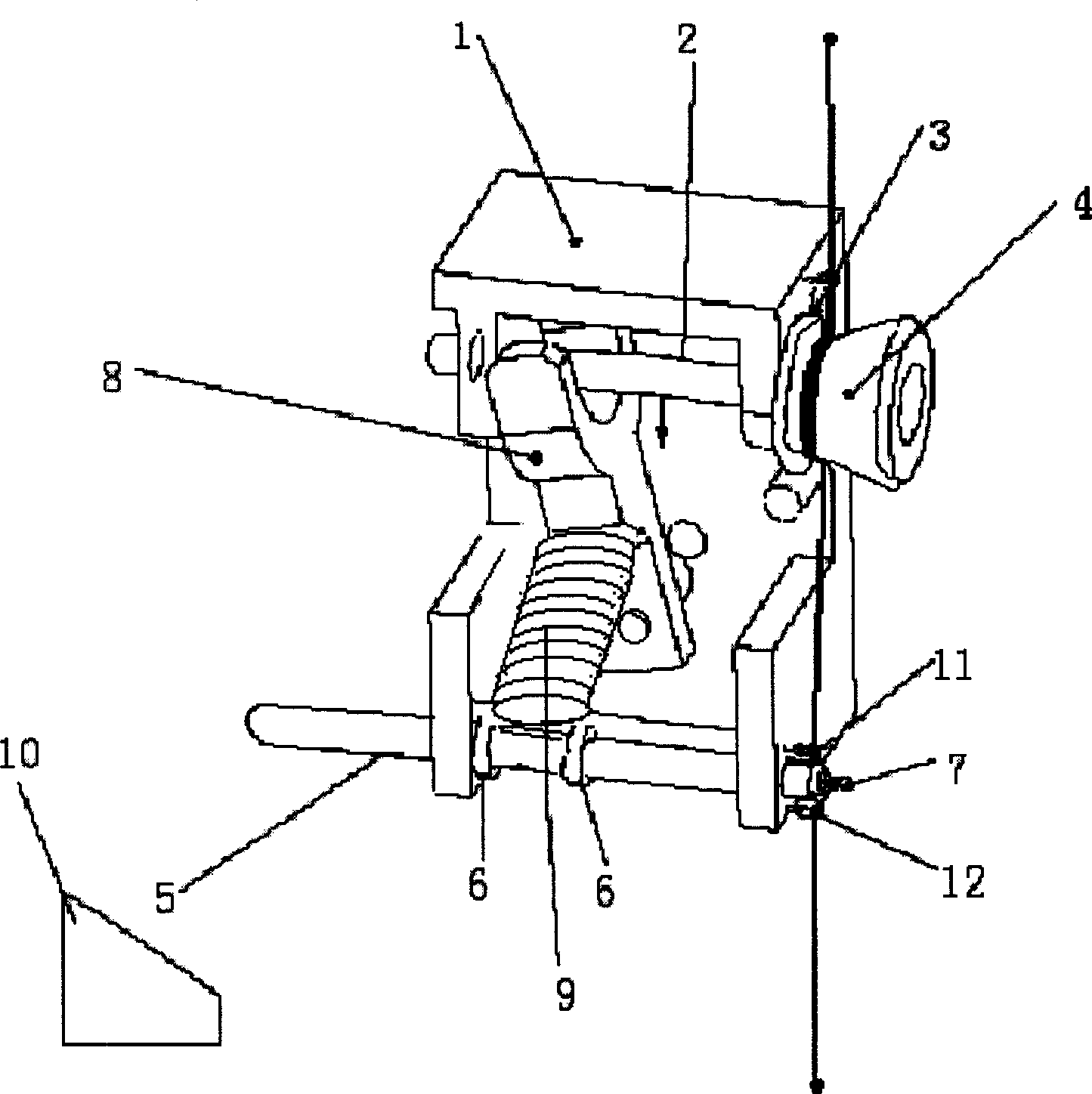

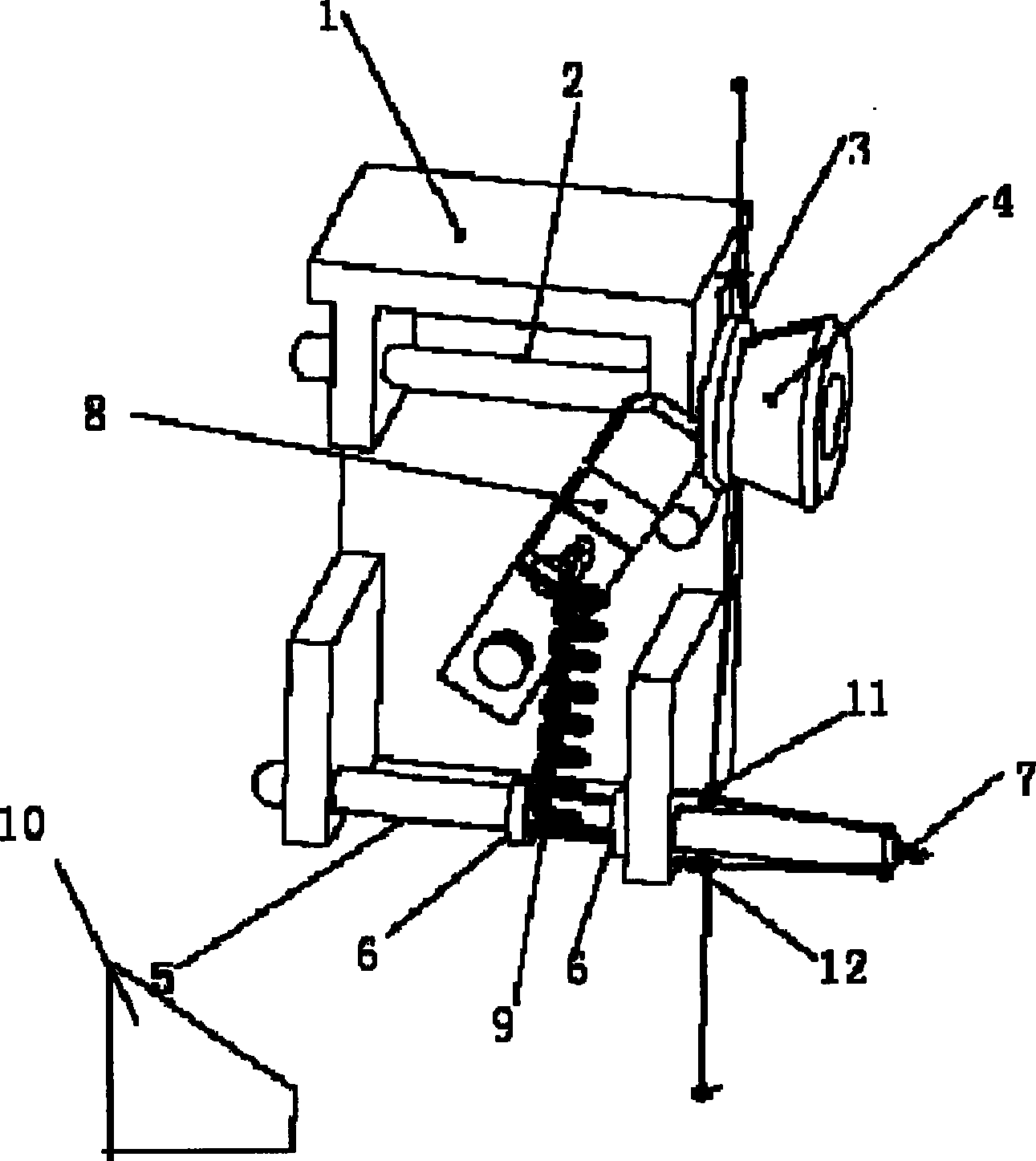

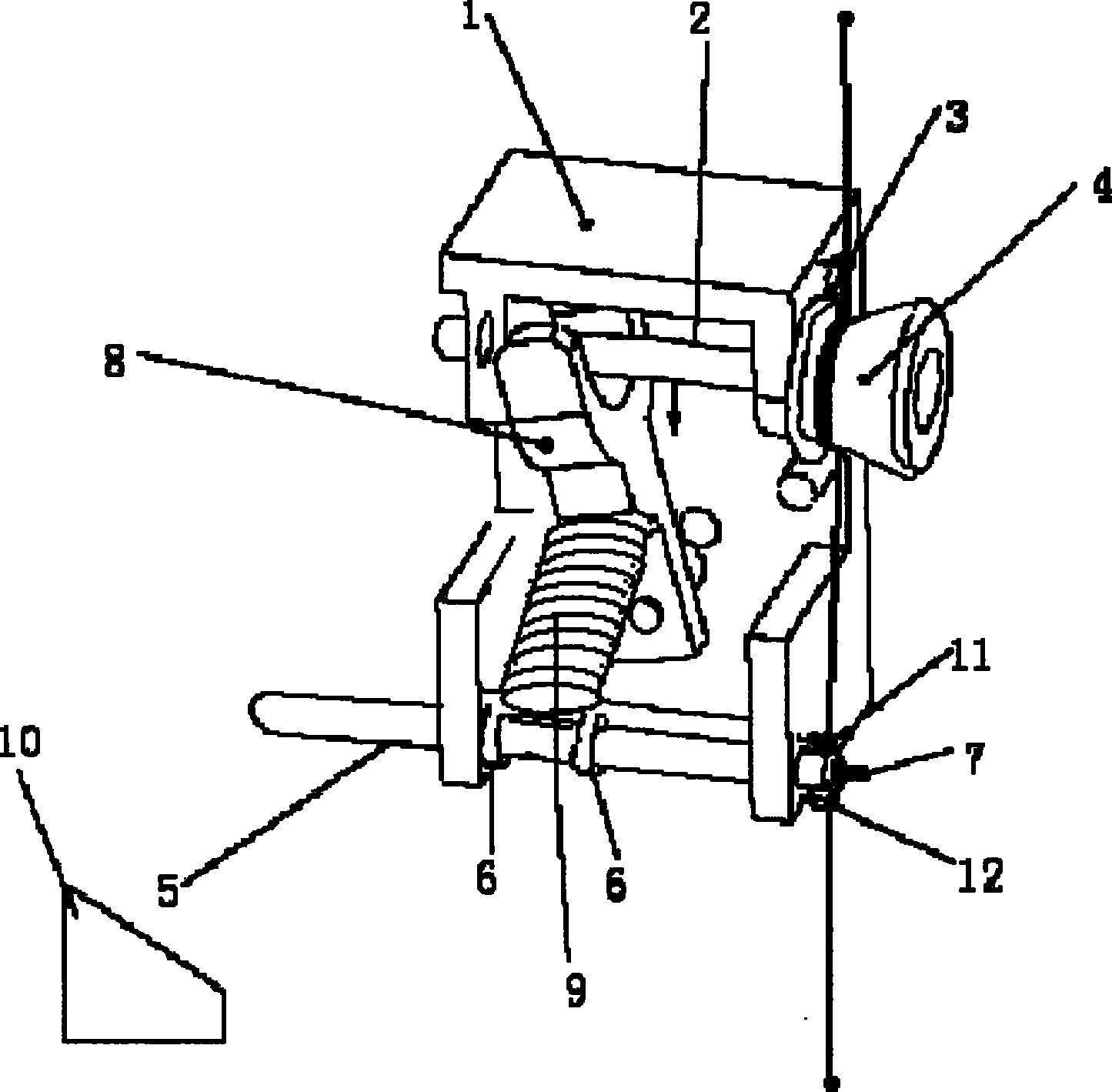

[0013] refer to figure 1 , figure 2 , a variable-thickness sewing needle bar thread take-up mechanism, including a mounting bracket 1, a horizontally arranged mounting shaft 2 is fixed on the mounting bracket 1, and a thread clamping gasket 3 and a thread clamping pad 3 are arranged on the mounting shaft 2 Nut 4 , the clamping washer 3 is slidably sleeved on the installation shaft 2 , and the clamping nut 4 is fixedly connected to the installation shaft 2 . Both the clamp spacer 3 and the clamp nut 4 are located on the outside of the mounting bracket 1, the clamp spacer 3 is located on the inside of the clamp nut 4, and the clamp spacer 3 and the clamp nut 4 to form a threading gap.

[0014] The mounting bracket 1 is pierced with a slide bar 5 that can slide horizontally, the slide bar 5 is located below the installation shaft 2, and the slide bar 5 between the two sides of the mounting bracket is provided with two stops. Sliding convex ring 6, the head of the slide bar 5 ...

Embodiment 2

[0019] refer to figure 1 , figure 2 The outer side of the mounting bracket is also provided with a second threading ring 11 and a third threading ring 12, the second threading ring 12, the third threading ring 13 and the threading ring 7 of the head of the slider are located at the On the same side of the mounting bracket 1 , the sliding bar 5 is located between the second threading ring 12 and the third threading ring 13 . This moment, the needle thread first walked around the threading slit, and then passed through the second threading ring 12, the threading ring 7, and the third threading ring 13 successively and drawn out. The rest of the structure and implementation are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com