Discharging system and method capable of implementing self-adaption adjustment of discharging speed

An adaptive adjustment and speed technology, applied to conveyor control devices, conveyors, vibrating conveyors, etc., can solve problems such as wasting manpower, wasting energy, and low efficiency, and achieve the effect of improving use efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

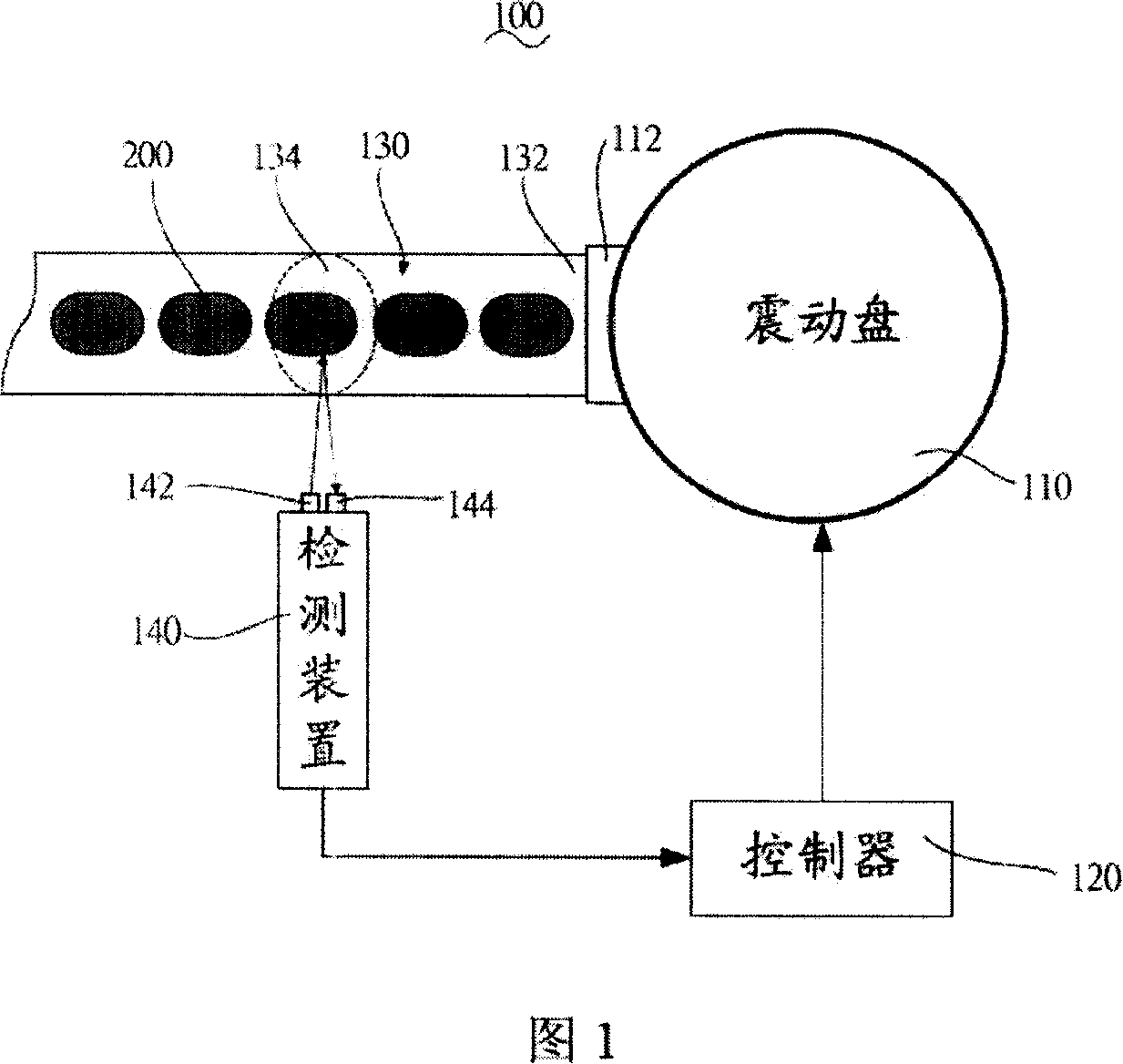

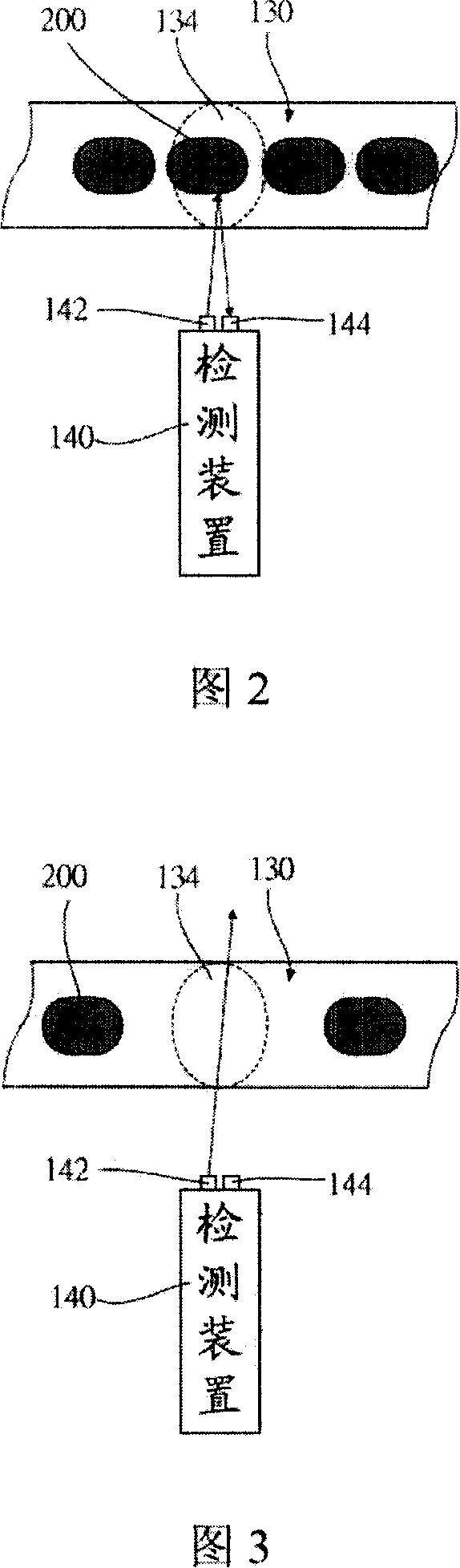

[0016] Referring to FIG. 1 , a discharge system 100 capable of adaptively adjusting the discharge speed provided by the first embodiment of the present invention includes a vibration plate 110 , a controller 120 , a conveying platform 130 , and a detection device 140 .

[0017] The vibrating plate 110 is used to contain the materials 200 and generate vibrations. The vibration plate 110 has a material outlet 112 . Generally, the vibrating plate 110 can be a hollow cylinder, and the inner wall thereof is provided with a spiral upward track. The spiral upward track communicates with the material outlet 112 and is used to guide the material 200 in the vibrating plate 110 to be discharged from the material outlet 112 to the conveying platform 130 during the vibrating process of the vibrating plate 110 .

[0018] The controller 120 is used to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com