Pixel structure and its manufacturing method

A technology of pixel structure and manufacturing method, which is used in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of inconsistent parasitic capacitance and uneven display, and achieve the effect of reducing parasitic capacitance and reducing parasitic capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

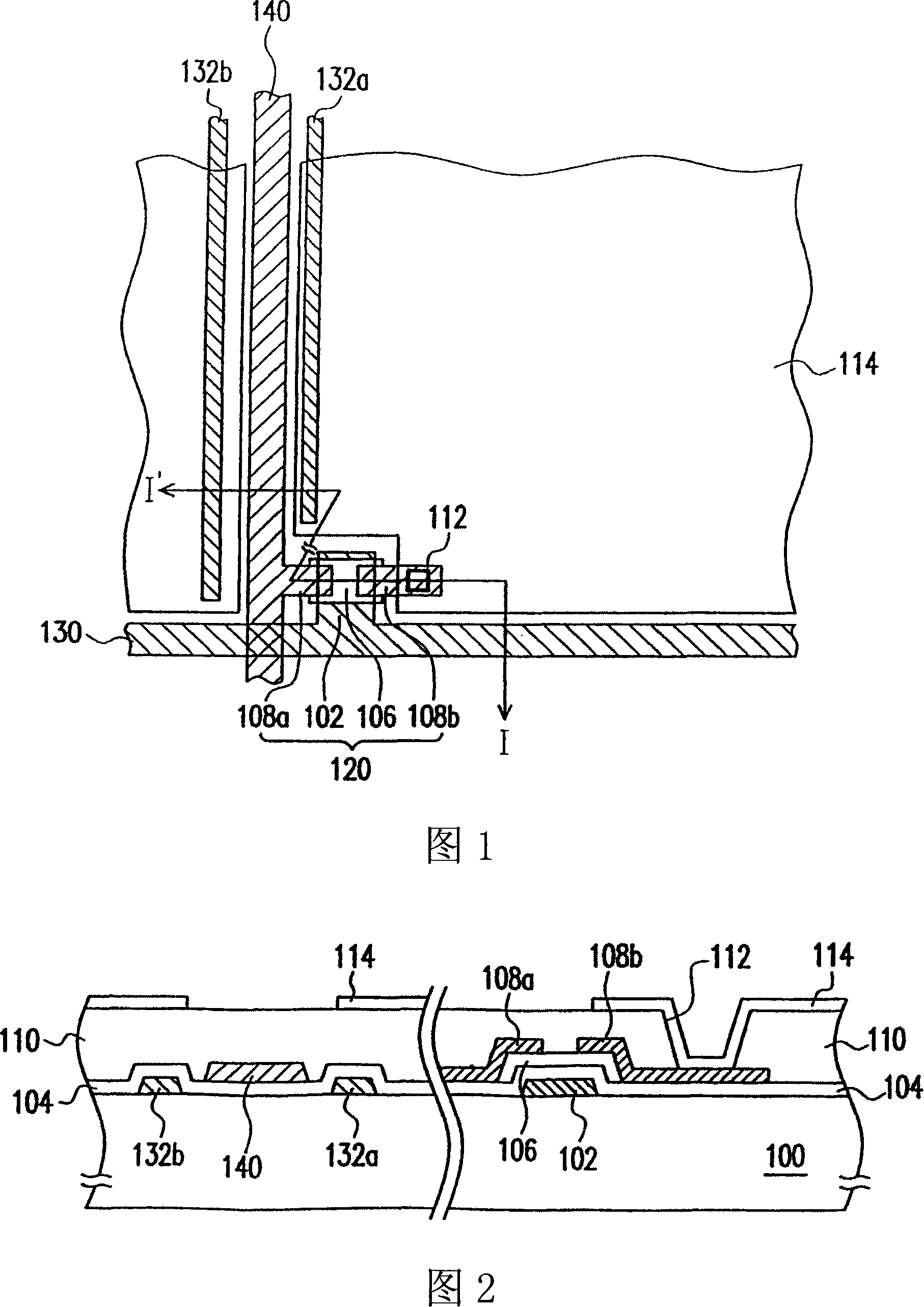

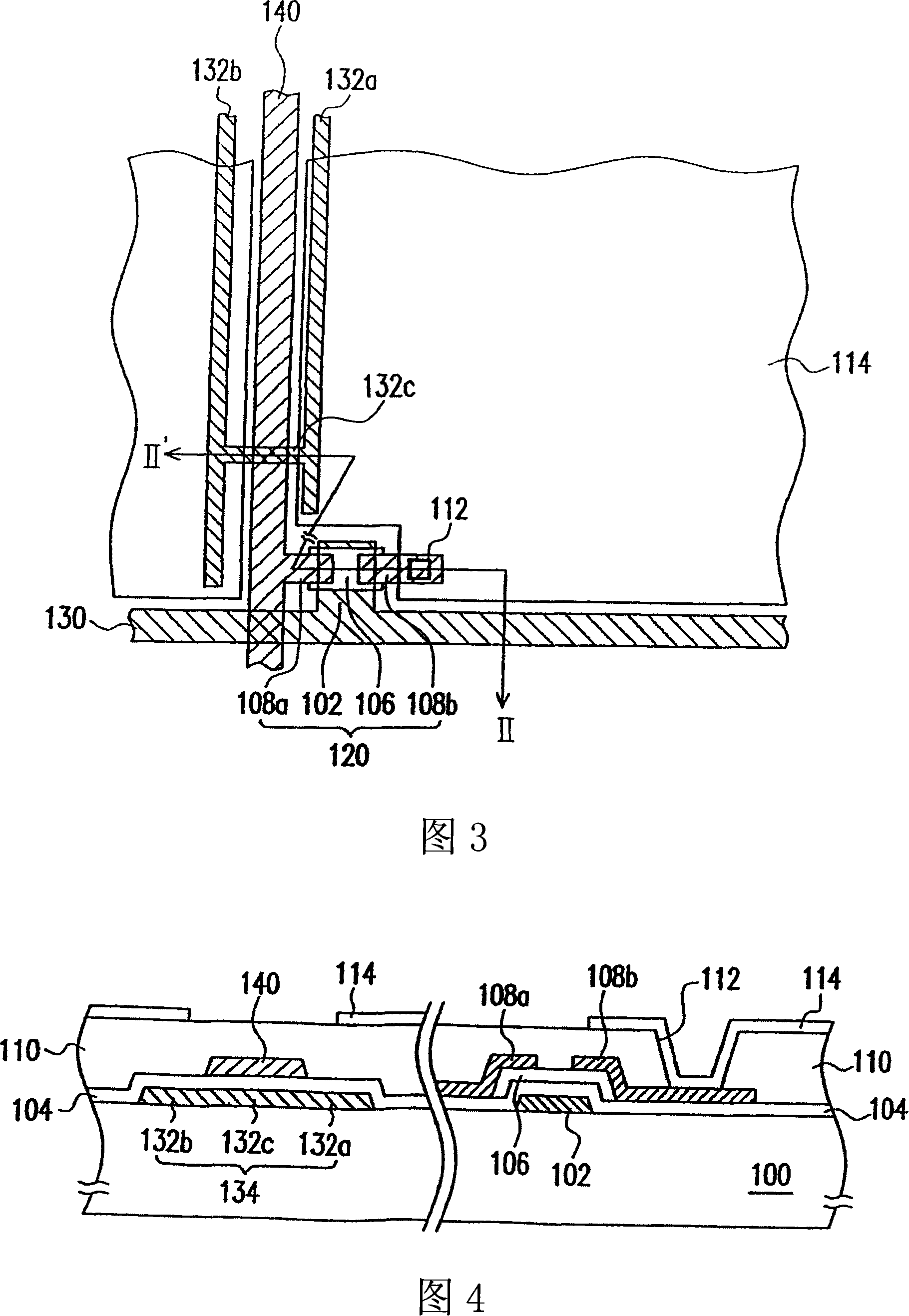

[0033] As shown in FIG. 3 , it is shown as the above-mentioned schematic diagram of a pixel structure according to a preferred embodiment of the present invention; as shown in FIG. 4 , it is shown as a schematic cross-sectional view from II-II' in FIG. 3 .

[0034] Referring to FIG. 3 and FIG. 4 , firstly, a transparent substrate 100 is provided, wherein the transparent substrate 100 is, for example, a glass substrate or a plastic substrate. Next, a gate 102 and a scan line 130 connected to the gate 102 are formed on the transparent substrate 100 , and a light-shielding layer 134 is formed on the transparent substrate 100 at the same time. Wherein, the light-shielding layer 134 is composed of a light-shielding portion 132a, 132b and a connecting portion 132c, and the light-shielding portion 132a, 132b is arranged on both sides of a predetermined data wiring, and the connecting portion 132c connects the light-shielding portion 132a, 132b. stand up.

[0035] In this embodiment,...

no. 2 example

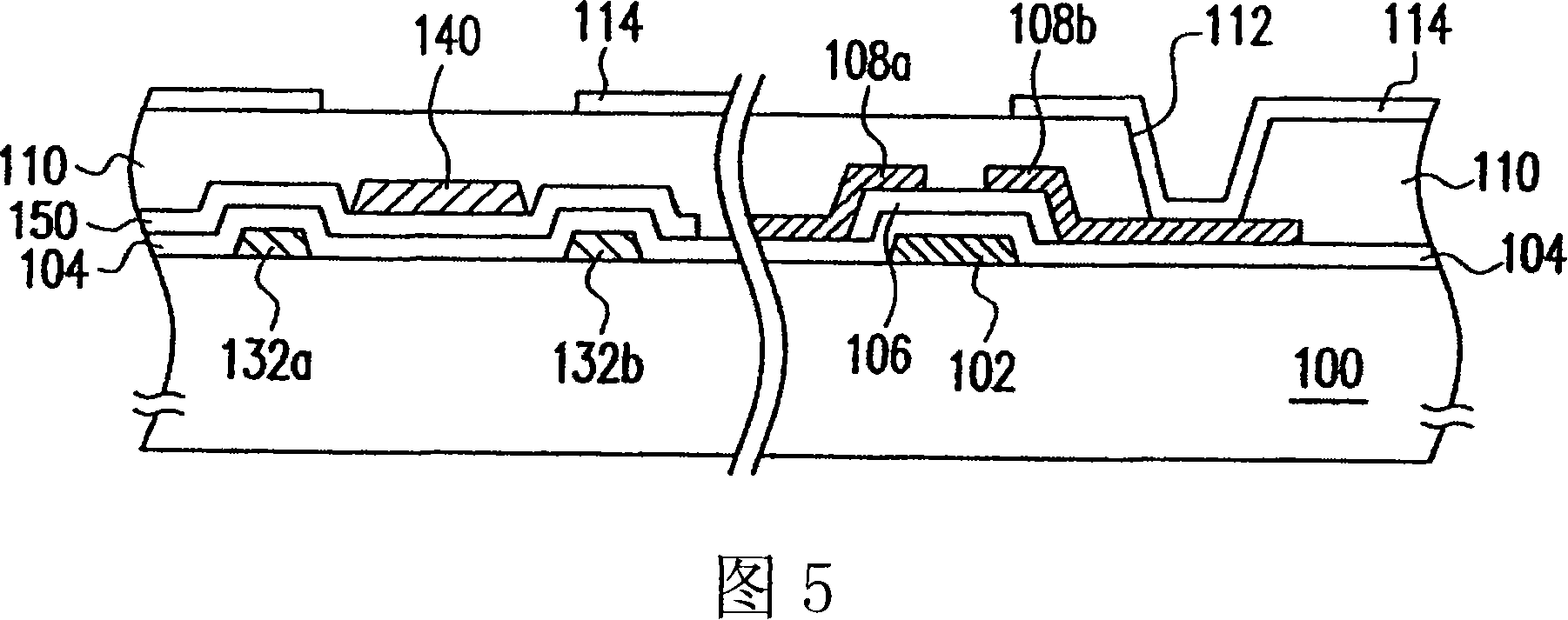

[0045] Another method of manufacturing a pixel structure that can prevent uneven display of the present invention is shown in FIG. 5 , which is a schematic plan view of a pixel structure according to another preferred embodiment of the present invention.

[0046] Referring to FIG. 5 , as previously described in the prior art, when the gate 102 and the scanning wiring 130 are formed on the transparent substrate 100 , the light-shielding layers 132 a and 132 b are also formed on the transparent substrate 100 . After that, a gate insulating layer 104 is formed on the transparent substrate 100 to cover the gate 102 , the scan wiring 130 and the light-shielding layers 132 a and 132 b. Next, a dielectric layer 150 is additionally formed on the gate insulating layer 104 on the light shielding layers 132a and 132b, wherein the material of the dielectric layer 150 is, for example, silicon nitride.

[0047] Next, a channel layer 106 , a source / drain 108 a / 108 b , and a data wiring 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com