Rotating springback wedging type electrically connected method and device

An electrical connection device and connection device technology, applied in flexible/rotatable wire connectors, clamping/spring connections, connections, etc., can solve the problem of poor reliability of plug sockets or couplers, failure to ensure synchronous insertion, and damage to electrical appliances and other problems, to achieve the effect of good electrical connection, excellent drop resistance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

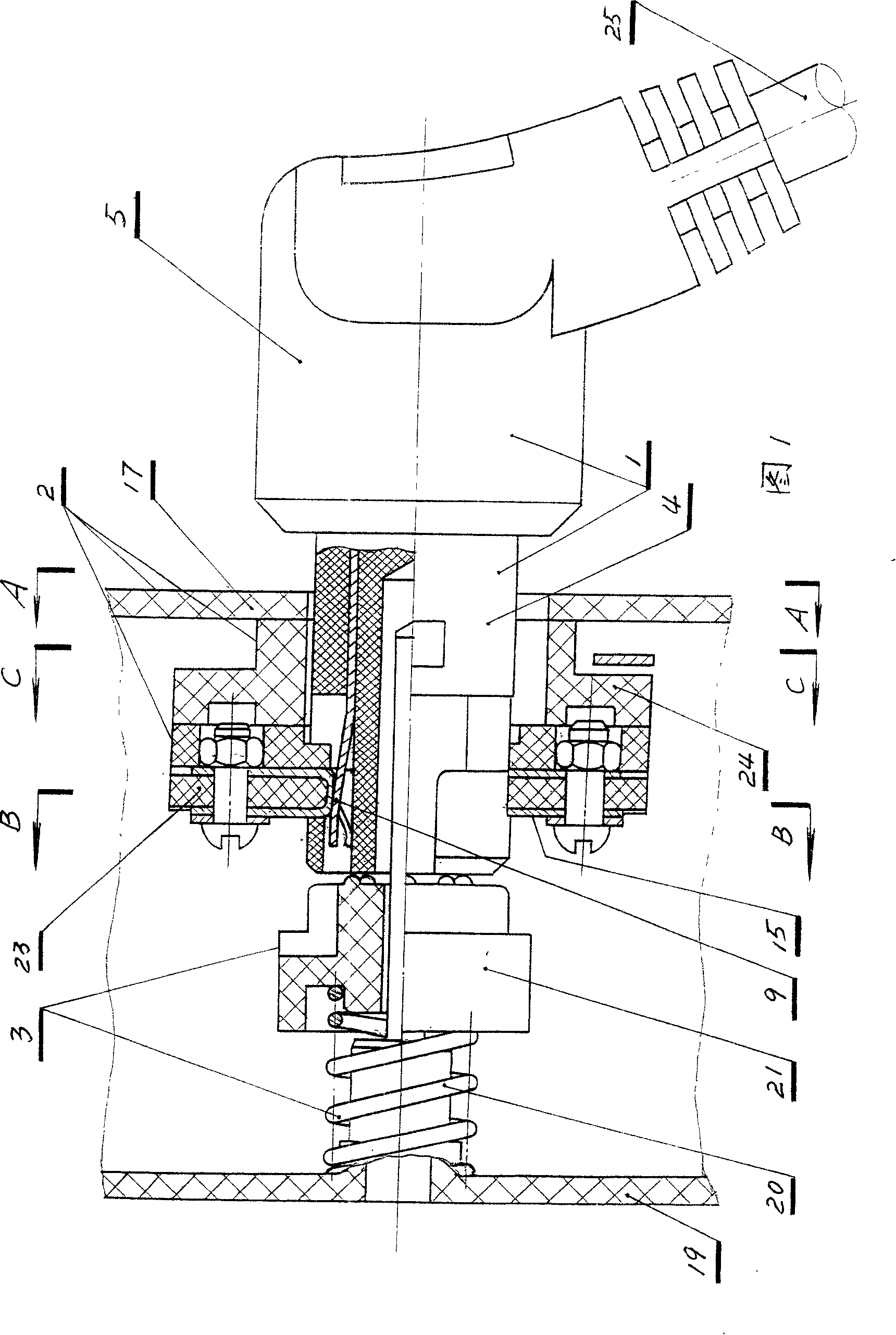

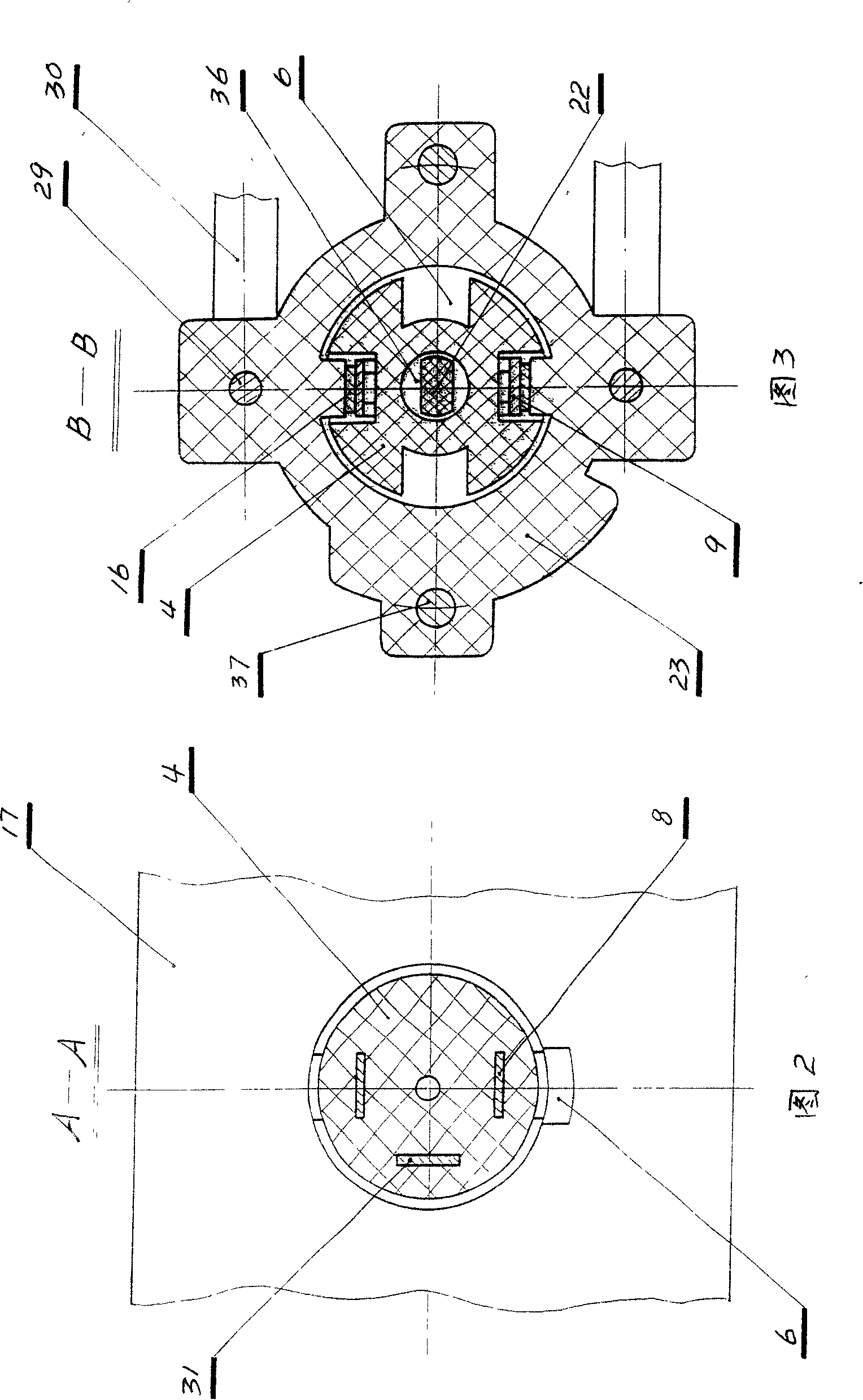

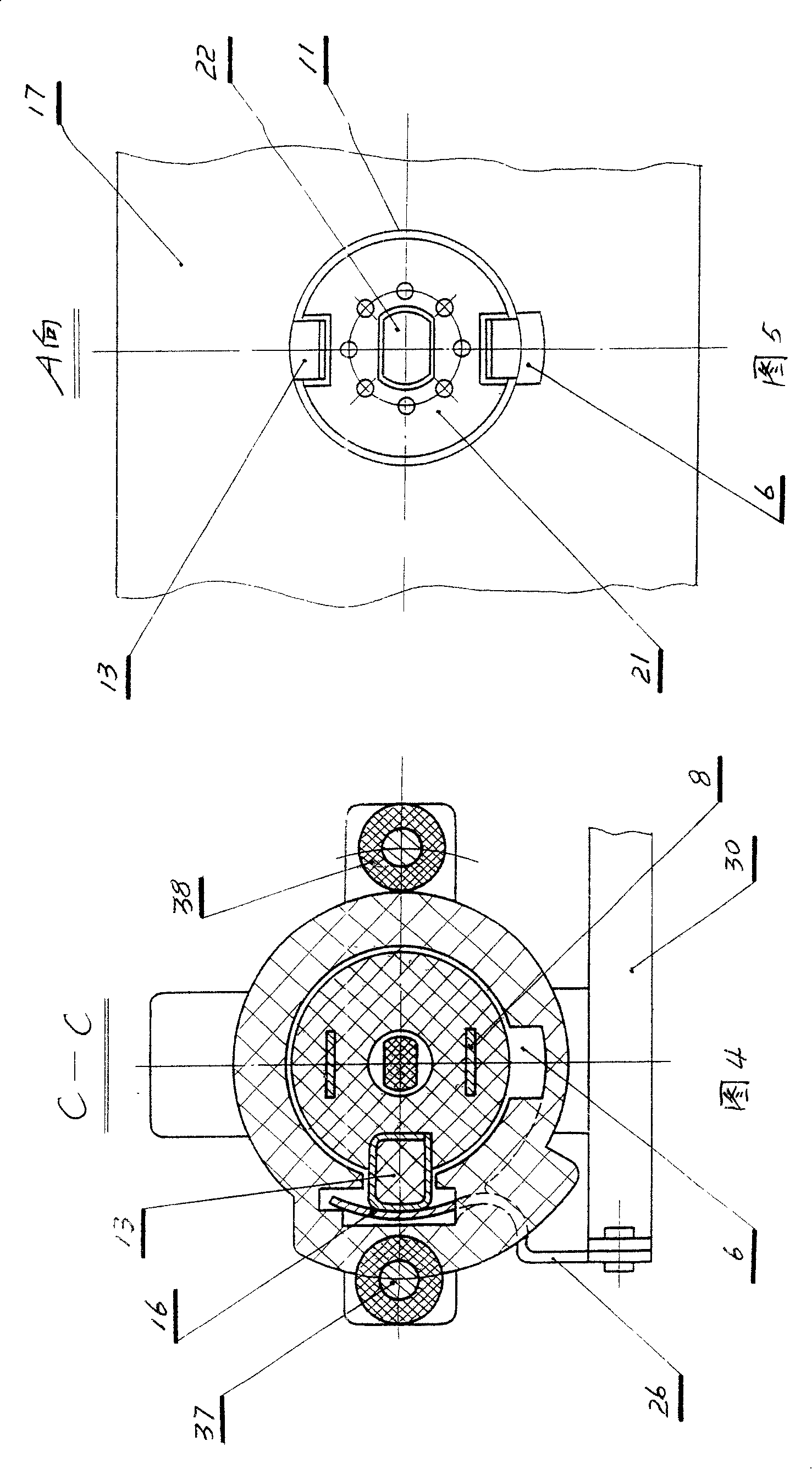

[0039] Please refer to Figure 1 to Figure 18. First, according to the required specifications, shape, size and appearance design, process, assemble, and then process the connecting head bolt body (4) and the connecting head operating body (5) with two guide positioning grooves (6) and One section has a wedging surface C (9), the metal contact piece A (8) connected to the electric wire (25) at its other end and a guide positioning boss (13) and one section has a wedging surface C (9) , the other end of which is connected to the grounded metal contact piece A (31) of the electric wire (25) and is ready to be used; similarly, according to the required specification, shape, size, appearance design, Process the connecting seat back cover (19) and the main body module [comprising the main body module A (23) and the main body module B (24)] with a connecting seat panel (17) and a positioning guide step column (22) Connecting seat bolt hole (11), two guiding positioning bosses (13) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com