End connecting method for extremely fine coaxial cables

An ultra-thin coaxial and connecting method technology, which is applied in the direction of connection, connecting parts, protective grounding/shielding devices, circuits, etc., can solve the problems of gap generation, unsuitable for ultra-thin coaxial cable 100 end connection, poor operability, etc.

Inactive Publication Date: 2010-11-24

SMK CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Furthermore, in the cutting operation of the central conductor 101, it is difficult to cut the flexible central conductor 101 with the same length so as to prevent protrusion from the connector 110, and there is contact between the central conductors 101 with inconsistent cutting, or contact with the shield cover (not shown) covering the periphery of the connector 110 to cause a short circuit

The problem caused by the diameter error of the above-mentioned center conductor 101 is that, if the outer diameter of the center conductor 101 is relatively large, although the center conductor 101 can be connected to the center conductor 101 by crimping or pressure welding Solve the problem by positioning the center contacts 111 with slits or crimp grooves for pressure welding, but at the connection parts of the center contacts 111 arranged at a narrow pitch to the central conductor 101, the formation of slits for pressure welding cannot be ensured. Or the size of the crimping groove becomes an unsolvable problem when connecting the ends of a plurality of ultra-thin coaxial cables 100 to a miniaturized connector.

In addition, in the ultra-fine coaxial cable 100 in which the central conductor 101 itself has a small diameter, if the central conductor 101 is connected to the central contact 111 by crimping or pressure welding, the central conductor 101 may come off from the central contact 111 or a gap may be generated. However, the problem of being unable to electrically connect with the central contact 111 with a predetermined contact pressure becomes a connection method that is not suitable for the terminal connection of the ultra-thin coaxial cable 100.

Therefore, each center conductor 101 needs to be connected to the center contact 111 by soldering or welding. Combining wiring is an extremely difficult operation, and it becomes an operation with poor operability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

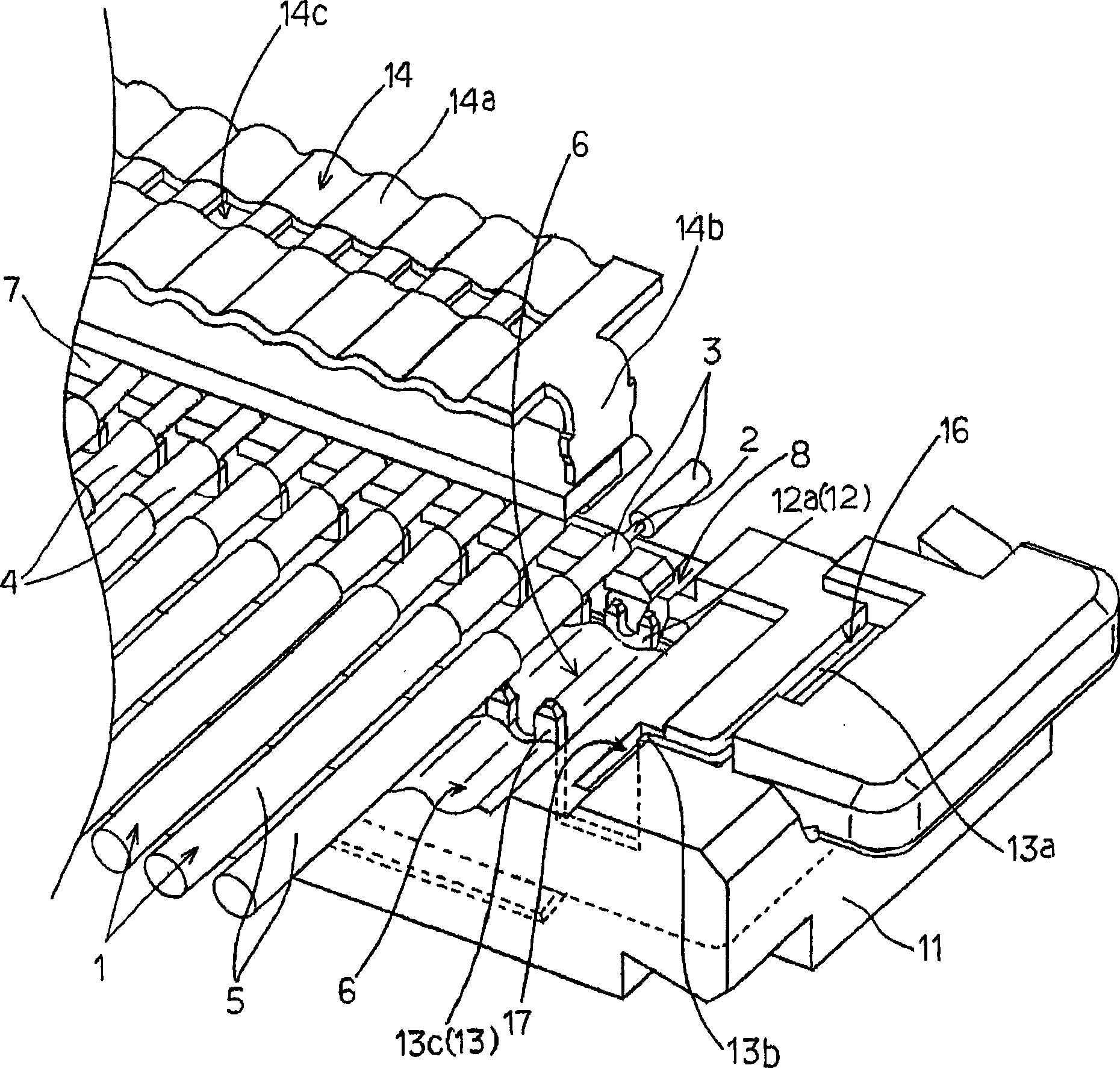

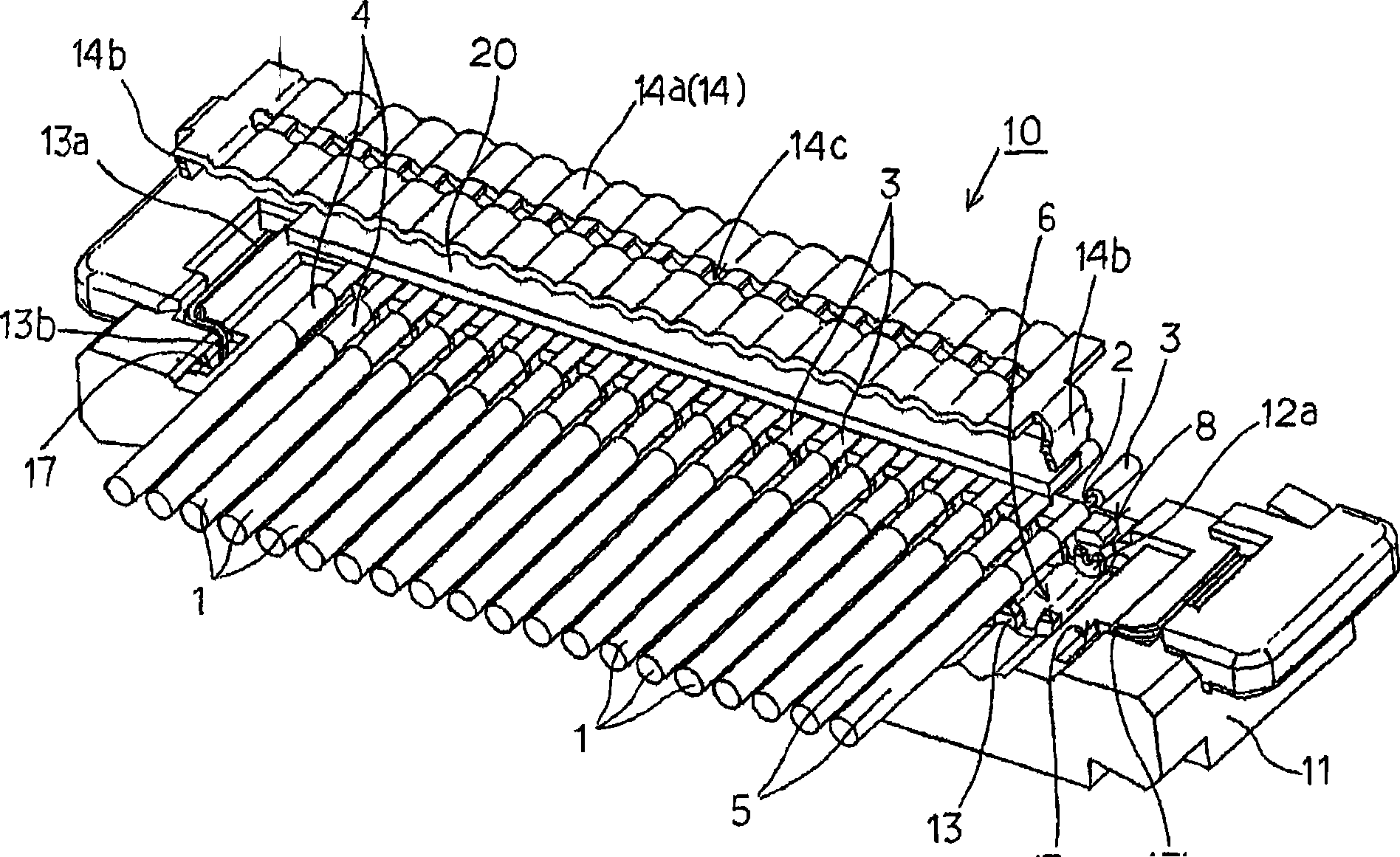

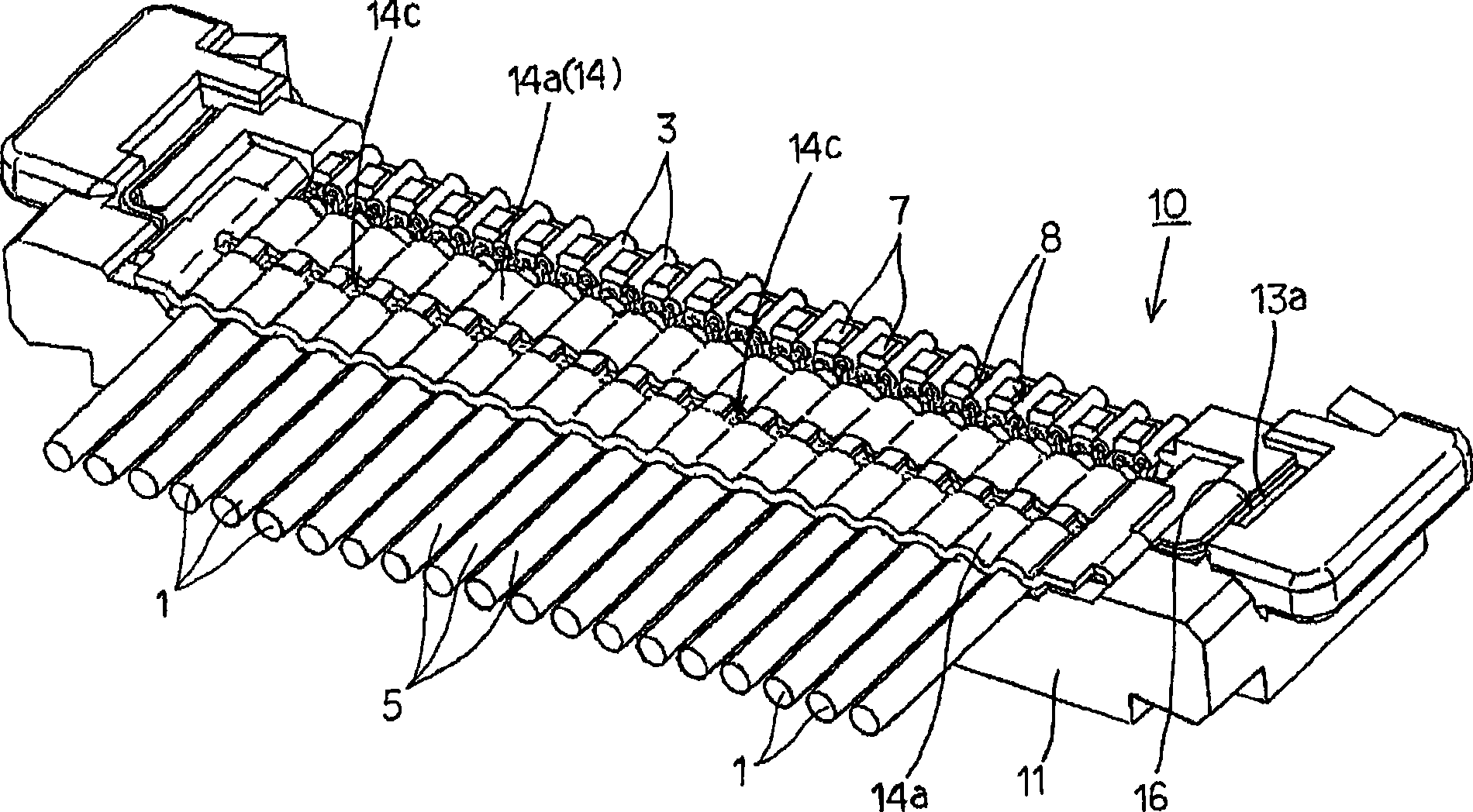

The present invention provides an end connecting method capable of connecting ultrathin coaxial cable of each end without locating multiple ultrathin coaxial cables arranged at equal interval of central contact of connector, comprising that: configuring ultrathin coaxial cable to the guiding slot disposed concavely at equal interval along arrangement direction on the insulation housing, retainingthe exterior conductor of multiple ultrathin coaxial cables arranged along arrangement direction and forward and backward direction and the solder plate between an earth plate fixed on the insulationhousing and a guiding slot, fusing the solder plate and soft soldering to the earth plate.The exterior conductor of the ultrathin coaxial cable is coupled electrically to the earth plate and fixed tothe insulation housing under arrangement condition, which is capable of connecting electrically the exposed front central conductor of exterior conductor to the central contact of connector.

Description

How to connect the end of micro coaxial cable technical field The present invention relates to a plurality of ultra-fine coaxial cables arranged on a connector at narrow intervals, and the central conductor stripped at the end of each ultra-fine coaxial cable is electrically connected to the central contact of the connector. How to connect the end of the shaft cable. Background technique With the miniaturization and multi-functionalization of electronic equipment, the thinning of coaxial cables has been promoted. For example, the use of ultra-thin coaxial cables with an outer diameter of the center conductor of about 0.3 mm, and by high-density mounting on printed circuit boards , Miniaturization of electronic components, etc., the ultra-thin coaxial cable is connected to the connector at a narrow pitch, so that the connector that connects multiple coaxial cables is also miniaturized. A micro coaxial cable is coaxially formed with a central conductor, an intermediate die...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01R13/648H01R43/02

Inventor 富樫晃司

Owner SMK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com