Indoline-like photosensitive dyestuff and application thereof

A technology of indoline dyes and dyes, which is applied in the field of indoline dyes and their applications, and can solve the problems of unstable service life of dye-sensitized batteries, slow carrier migration rate, and difficult packaging technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

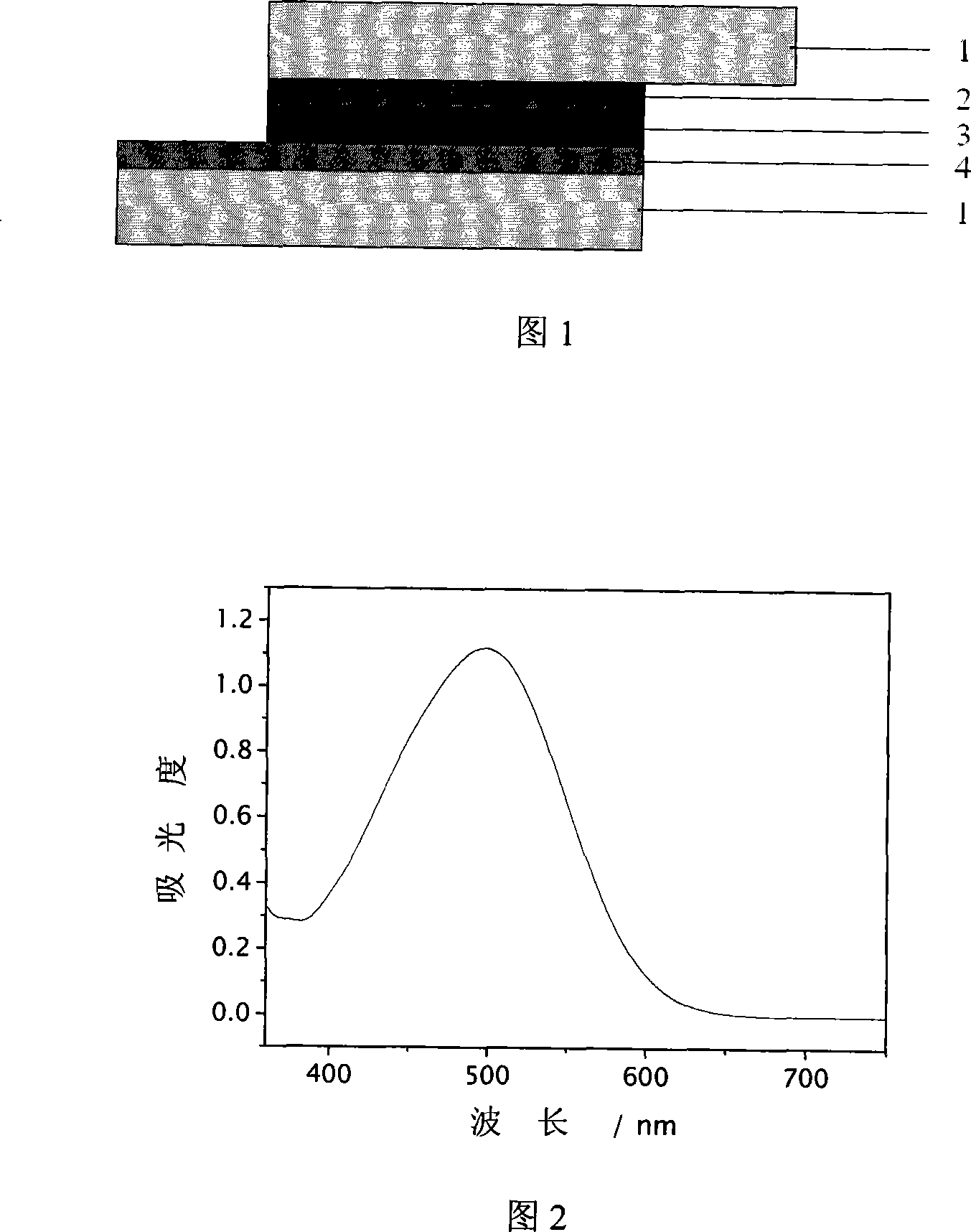

[0025] The preparation method of the quasi-solid-state dye-sensitized solar cell device comprises the following steps:

[0026] A) The nano-titanium dioxide colloid is evenly coated on the transparent conductive glass, dried at room temperature, treated at 400° C. for 30 minutes, and cooled to obtain a nano-titanium dioxide electrode with a thickness of 4 microns to 5 microns;

[0027] B) Heating the above-mentioned nano-titanium dioxide electrode to 80°C, and then immersing it in a concentration of 10 -4 Mole / L of the compound represented by formula (1) in solution for 12 hours (sensitization). Then take it out, rinse it with the corresponding solvent, and dry it;

[0028] C) A quasi-solid-state dye-sensitized solar cell device is composed of a nano-titanium dioxide electrode sensitized by the compound represented by formula (1), a platinum-coated conductive glass, and a quasi-solid electrolyte.

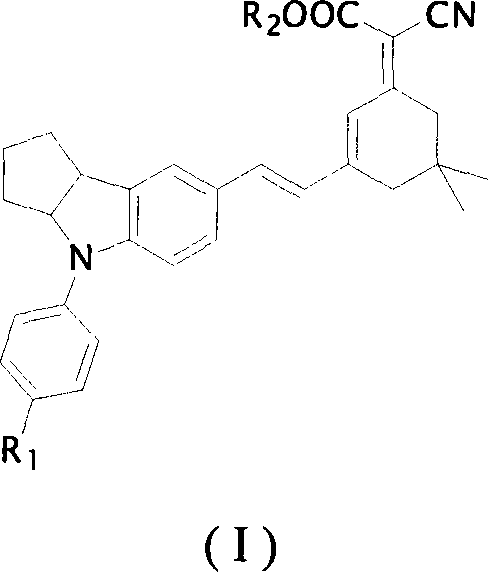

[0029] Adopt existing two-electrode system (B.O'Regan, M.Grtzel, Nature, 199...

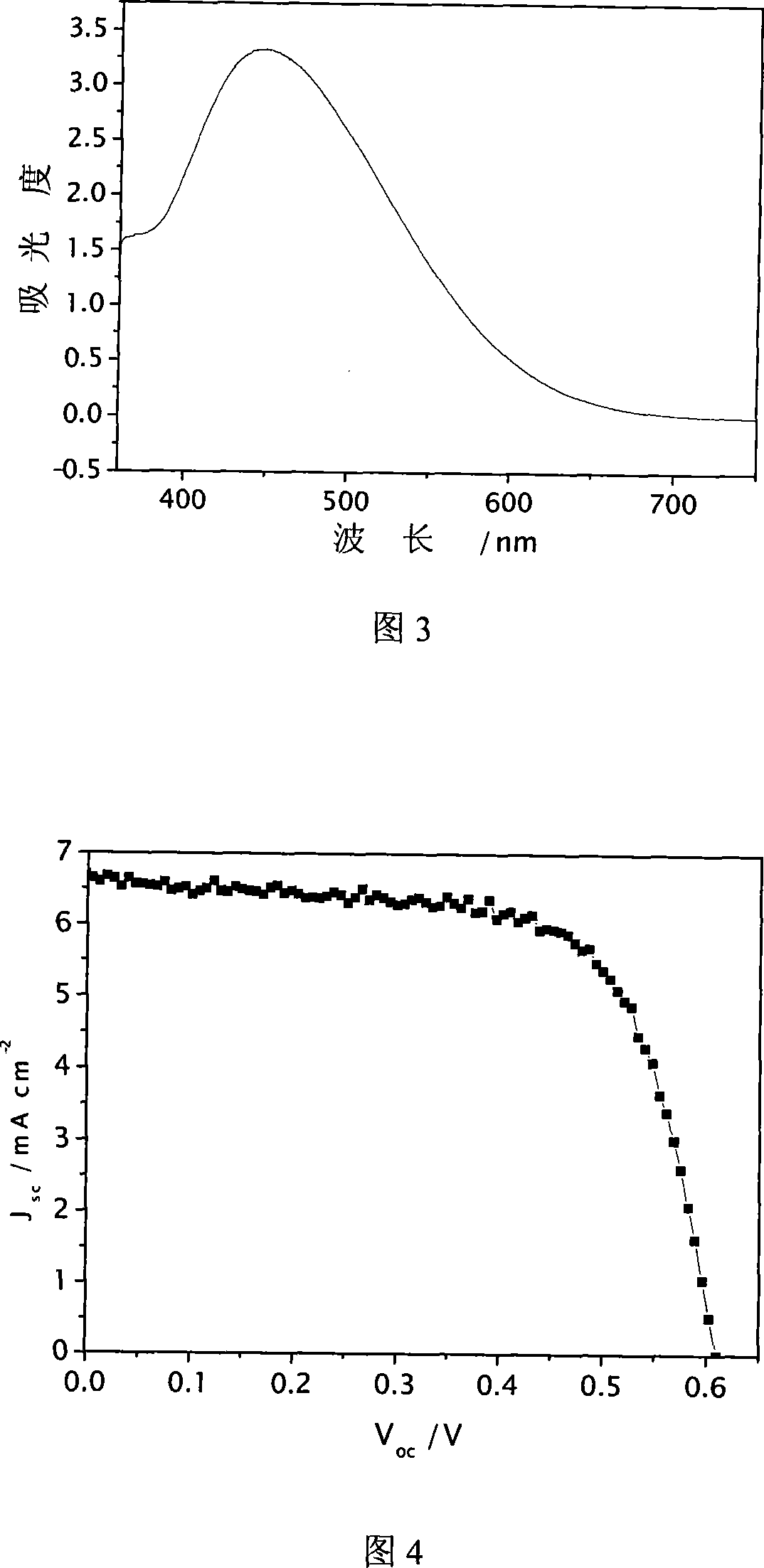

Embodiment 1

[0032]

[0033] In a 250 mL three-necked flask, 15 g of isophorone, 11.3 g of ethyl cyanoacetate, 1.54 g of ammonium acetate, 6 mL of acetic acid and 50 mL of toluene were sequentially added, and the reaction was refluxed for 18 h under argon protection. The reactant was poured into 200mL of water, stirred well and then separated. The organic layer was dried and distilled under reduced pressure. The fraction at 155-160°C was taken to obtain 17.3g of dark yellow viscous liquid, compound 2, with a yield of 74%.

[0034]

[0035] Add 47g of compound a, 84g of compound b, 3.6g of copper powder, 80g of potassium carbonate and 420mL of dichlorobenzene into a 1500mL three-neck flask, heat up to 150-160°C under Ar protection, and stir for 48 hours. After the reaction was completed, the solvent dichlorobenzene was distilled off under reduced pressure. The solid was extracted three times with 300 mL / time of dichloromethane, and the obtained liquid was spin-dried, and column chroma...

Embodiment 2

[0047]

[0048] In a 250mL three-neck flask, 15g of isophorone, 11.3g of ethyl cyanoacetate, 1.54g of ammonium acetate, 6mL of acetic acid and 50mL of toluene were respectively added, and the reaction was refluxed for 18h under the protection of argon. The reactant was poured into 200mL of water, stirred well and then separated. The organic layer was dried and distilled under reduced pressure. The fraction at 155-160°C was taken to obtain 17.3g of dark yellow viscous liquid, compound 2, with a yield of 74%.

[0049]

[0050] Add 47g of compound a, 92g of compound d, 3.6g of copper powder, 80g of potassium carbonate and 420mL of dichlorobenzene into a 1500mL three-necked flask, heat up to 150-160°C under Ar protection, and stir for 48 hours. After the reaction was completed, the solvent dichlorobenzene was distilled off under reduced pressure. The solid was extracted three times with 300 mL / time of dichloromethane, and the obtained liquid was spin-dried, and column chroma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap