Transformer

A technology of transformers and iron cores, applied in the field of transformers, can solve problems such as increasing the cost of transformer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

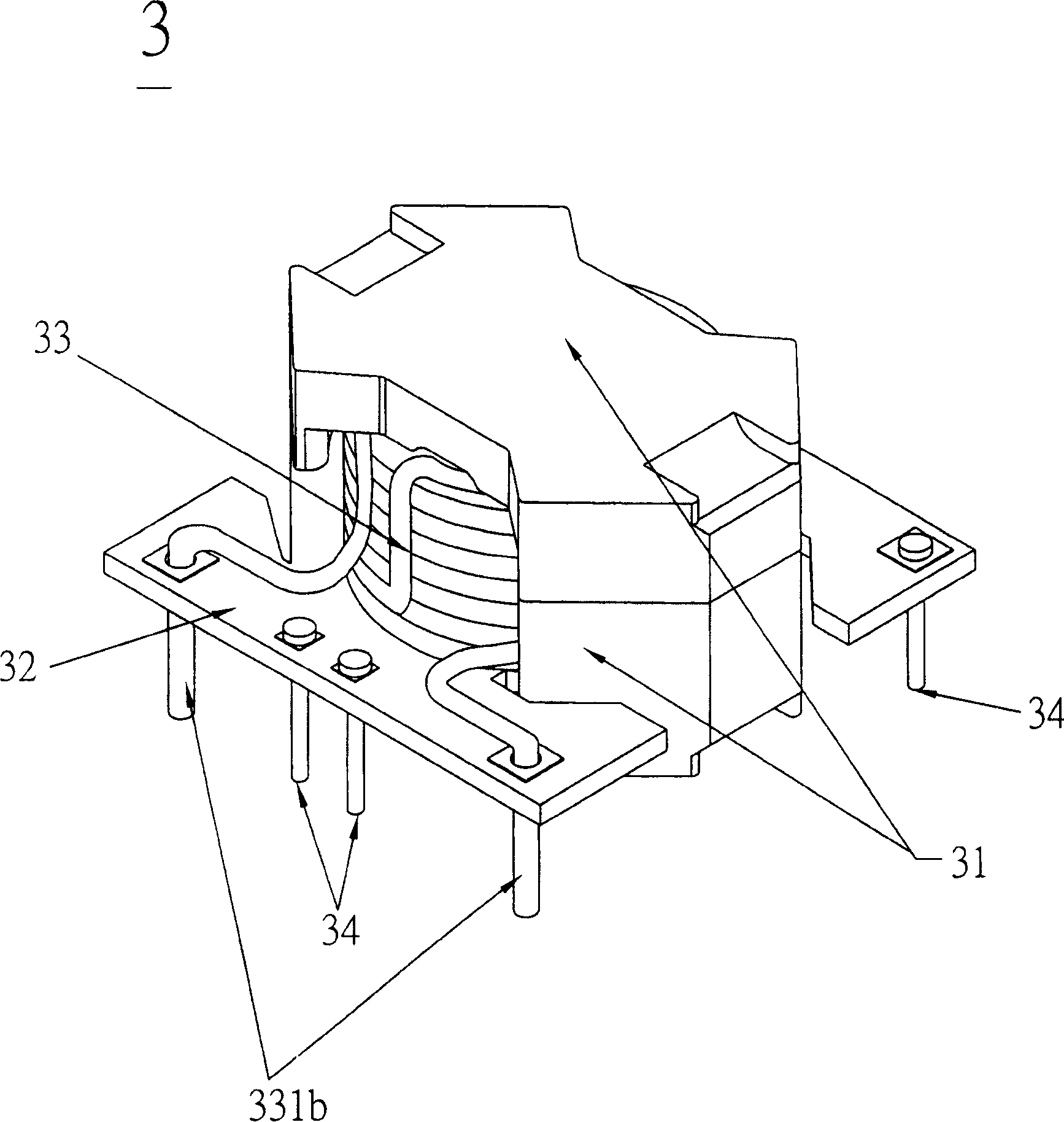

[0038] The following implementation manners will be described according to the related drawings of a transformer 3 in a preferred embodiment of the present invention, wherein the same components will be denoted by the same reference symbols.

[0039] Please refer to Figure 3A and Figure 3B As shown, a transformer 3 according to a preferred embodiment of the present invention includes a core set 31 , a circuit board 32 and a winding set 33 , and the transformer 3 is used in an electronic device.

[0040] The iron core set has a first iron core 311 and a second iron core 312. After the two are clamped, a circuit board 32 and a winding group 33 are provided in the middle, wherein the winding group 33 further includes an insulating coil. 331 and a conductive sheet 332, and the conductive sheet 332 is placed between the double-layer structure formed after the insulating coil 331 is wound. The first iron core 311 and the second iron core 312 of the iron core group 31 have a rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com