Shape retaining member and shape retaining structure

A technology for retaining parts, three-dimensional shapes, applied in the direction of transportation and packaging, packaging, wood compression, etc., to achieve stable shape retention and easy attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention (hereinafter simply referred to as "embodiments") will be described below with reference to the accompanying drawings.

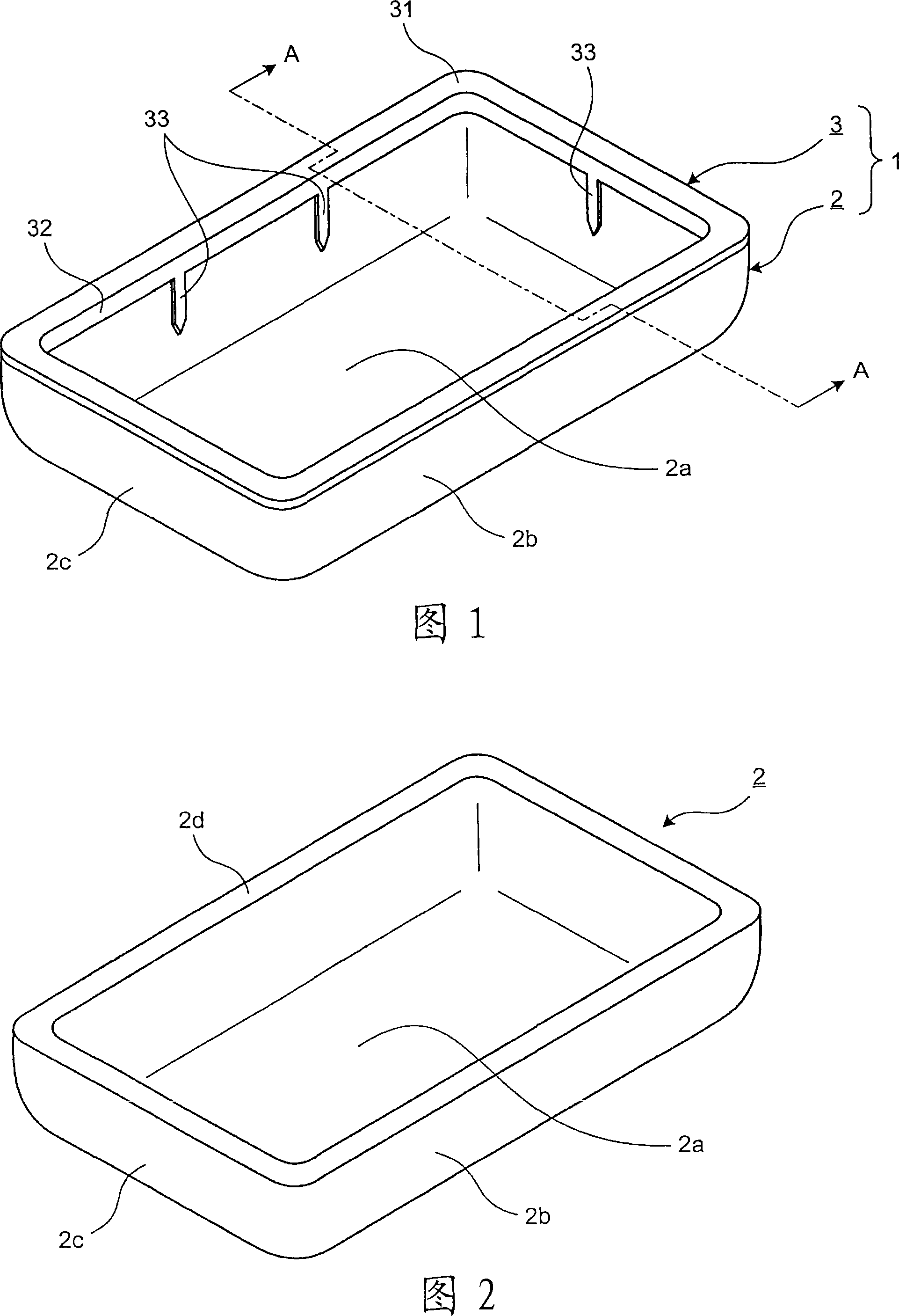

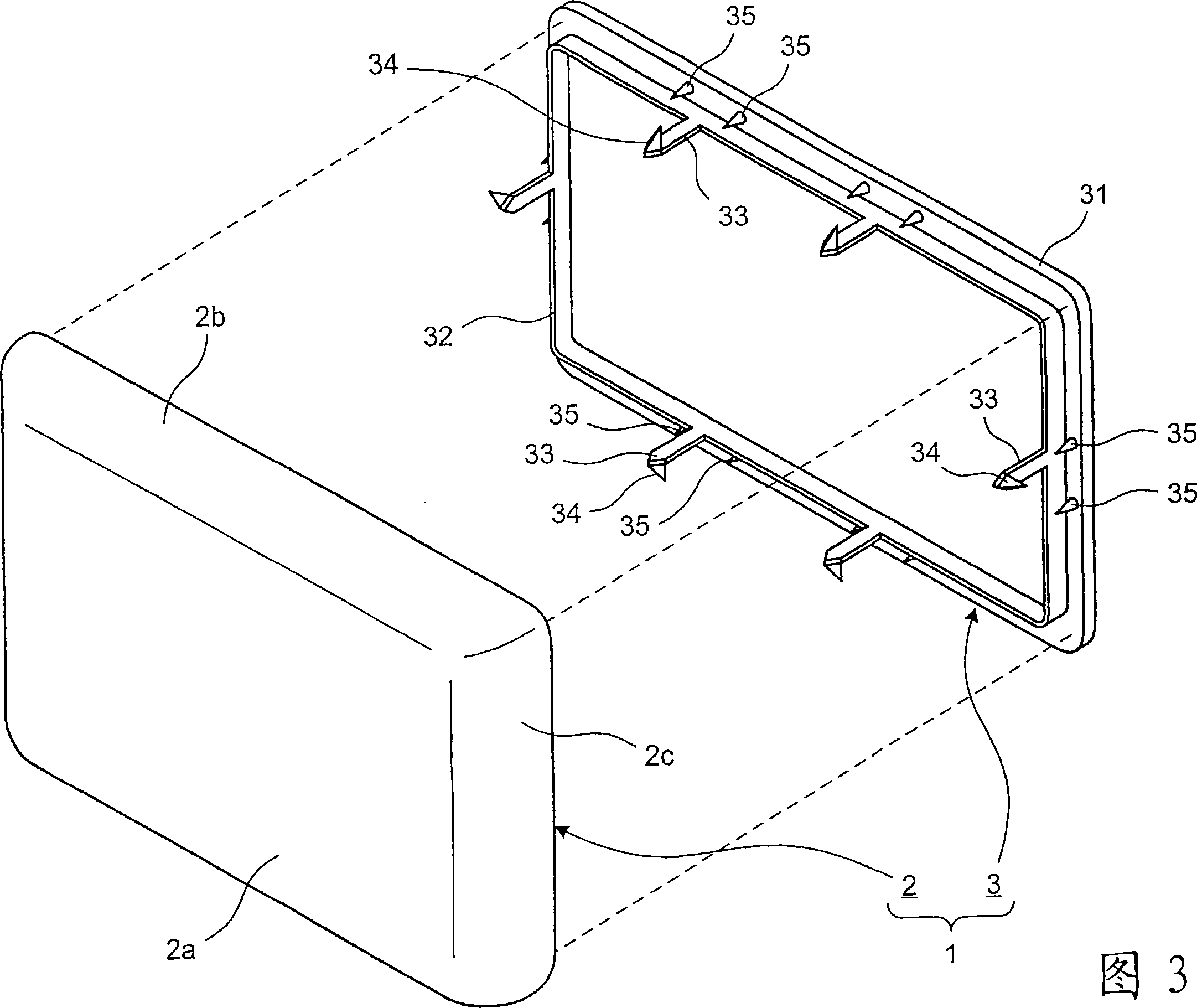

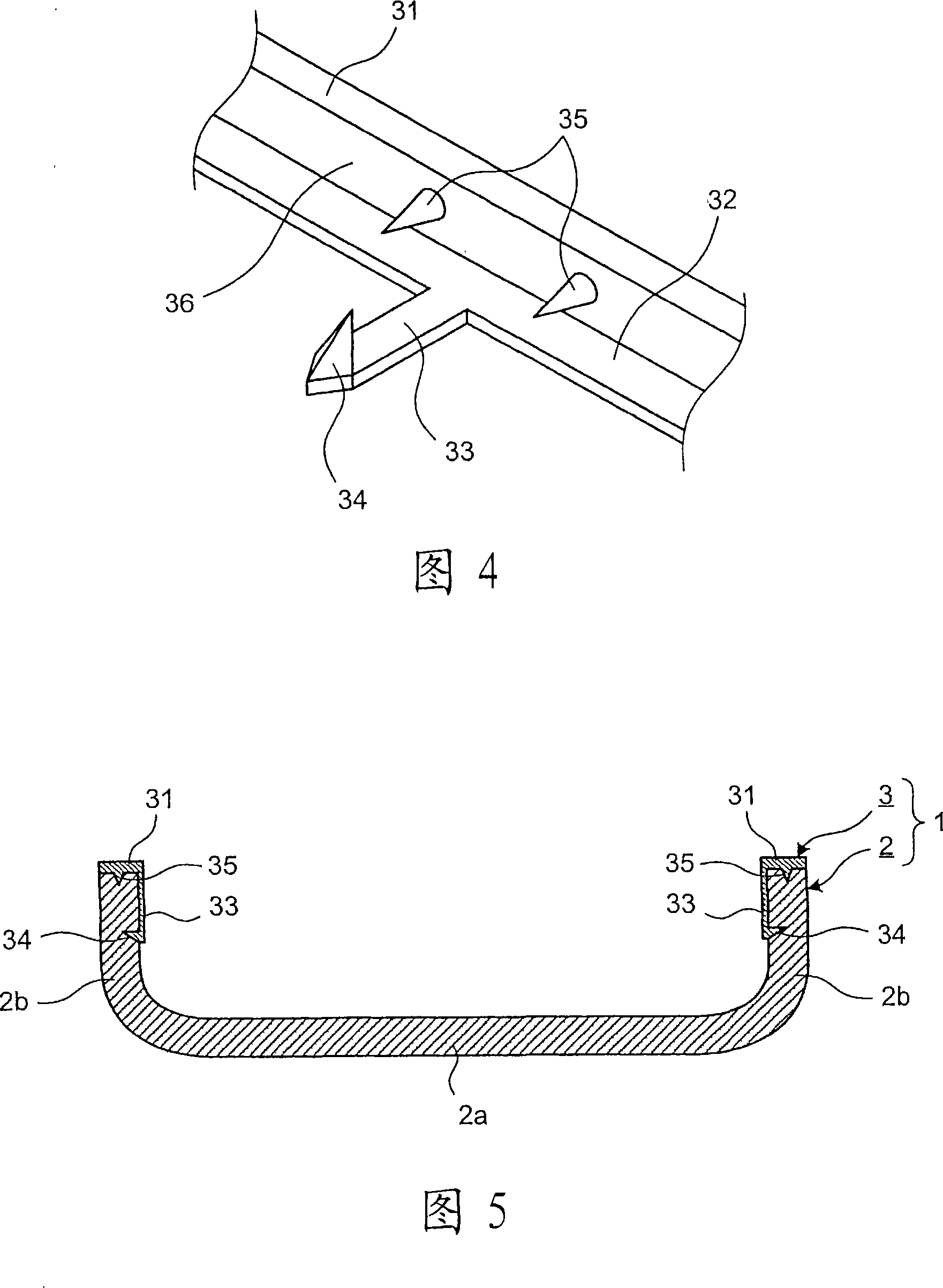

[0030] Fig. 1 is a perspective view of the configuration of a compressed wooden product including a wooden piece formed by compression (compressed wooden piece) and a shape retainer of a first embodiment of the present invention attached to the compressed wooden piece. Fig. 2 is a perspective view showing the structure of compressed wood of the compressed wood product shown in Fig. 1 . A compressed wood product 1 shown in FIG. 1 includes a substantially bowl-shaped wooden piece 2 (wooden piece), and a metal shape holder 3 attached to the wooden piece 2 . Fig. 3 is an exploded perspective view of the compressed wood product 1 of Fig. 1 viewed from its bottom side. The configurations of the wooden member 2 and the shape retaining member 3 will be described below with reference to FIGS. 1 to 3 .

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com