Electrode mixture paste applying method and device

A coating method and a coating device technology, which are applied to the surface coating liquid device, electrode collector coating, electrode manufacturing, etc., can solve the problem of inability to perform continuous welding, long welding time, and obstruction of roller electrode rotation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In water with a wet ball mill, the composition formula MmNi 3.55 co 0.75 mn 0.4 Al 0.3 The shown hydrogen storage alloy was pulverized to an average particle diameter of 30 µm to obtain a hydrogen storage alloy powder. After immersing the hydrogen storage alloy powder in an alkaline aqueous solution for surface treatment, 10 kg of a carboxymethyl cellulose aqueous solution having a solid content ratio of 1.5% and 0.4 kg of Ketjen black were added to 100 kg of the hydrogen storage alloy powder. After kneading, 1.75 kg of an aqueous solution of styrene-butadiene copolymer rubber particles having a solid content ratio of 40% was added and stirred to prepare electrode mixture slurry 5 .

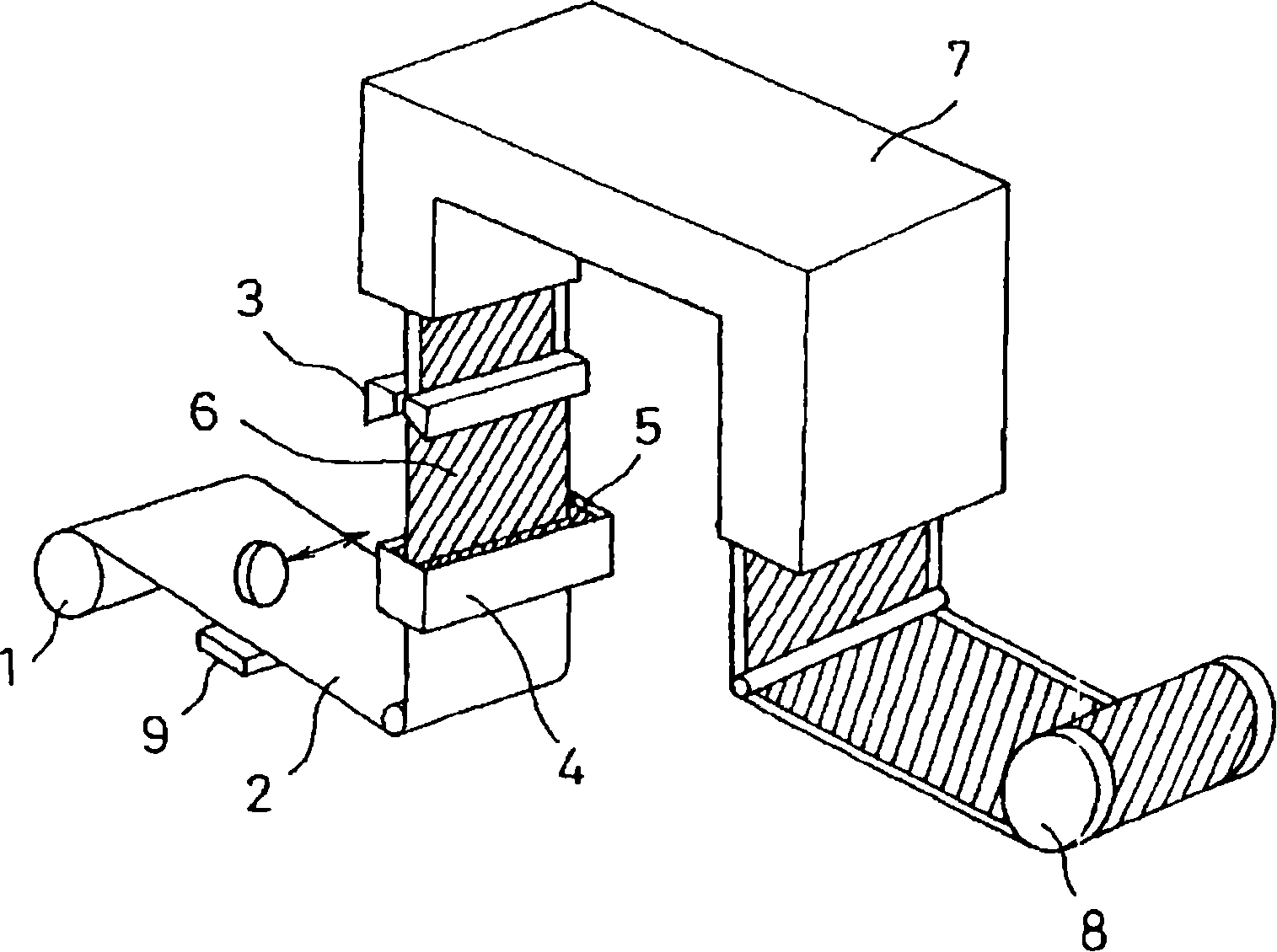

[0024] On both sides of the core material 2 (the total length of one coil is 200m) consisting of a nickel-plated iron punching metal with a thickness of 60 μm, a width of 300 mm, a punching diameter of 1 mm, and an opening ratio of 42%. , while scraping 20 mm of the electrode mixture s...

Embodiment 2

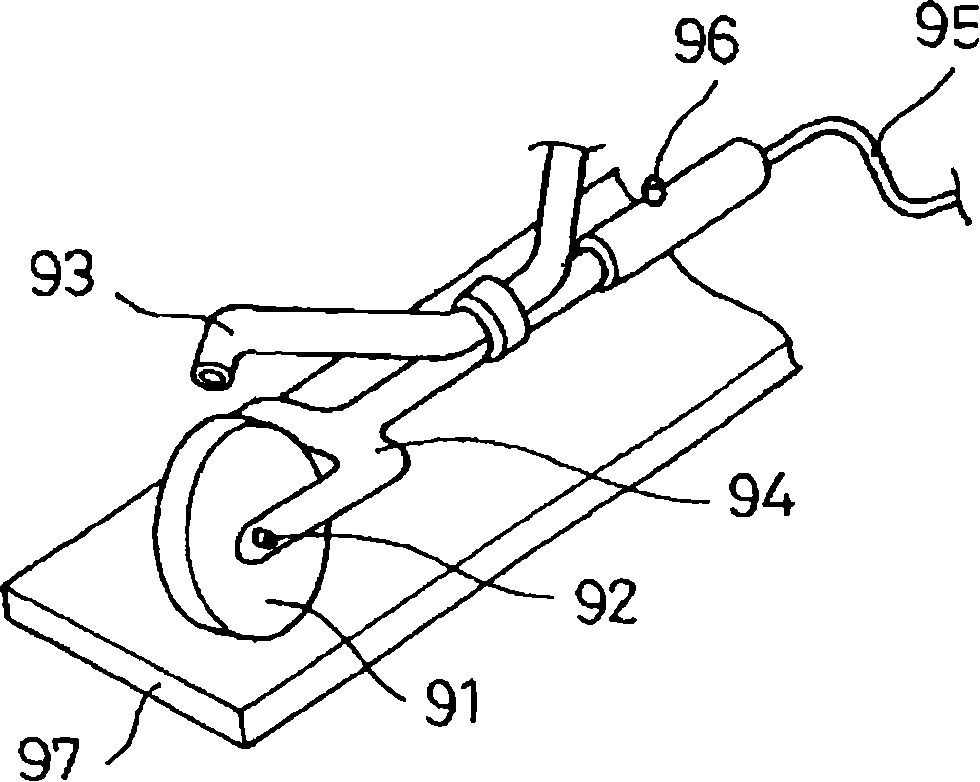

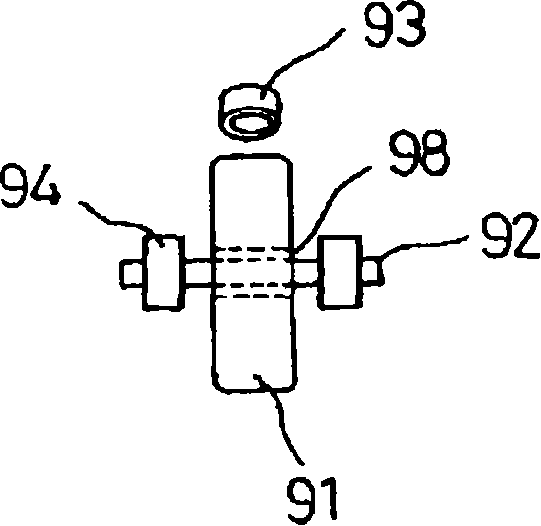

[0028] With respect to Example 1, except that the roll electrode 91, the roll pin 92, the roll holder 94, and the plate electrode 97 were made of tungsten, it carried out similarly to Example 1, and produced the slurry coating sheet 6.

[0029]In the four times of seam welding, the problem that the roller electrode 91 did not rotate did not occur. In addition, after coating over 1000 m, the distance from one end of the core material 2 to the coated part of the electrode mixture slurry 5 was measured on the rearmost part (the part where the coating was completed) of the slurry coated sheet 6. Size, the result is relative to the initial set value of 20mm, its offset is 0.6mm.

Embodiment 3

[0031] With respect to Example 1, except that the welding current and the action of gas injection are linked by a sequencer, and air (compressed air) is injected from the gas injection port 93 only when the switch 96 is pressed, the same method as in Example 1 is produced. Slurry coated sheet 6.

[0032] In the four times of seam welding, the problem that the roller electrode 91 did not rotate did not occur. In addition, after coating over 1000 m, the distance from one end of the core material 2 to the coated part of the electrode mixture slurry 5 was measured on the rearmost part (the part where the coating was completed) of the slurry coated sheet 6. Size, the result is relative to the initial set value of 20mm, its offset is 0.05mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap