Electric mounting box and cooling storage

A technology for electrical installation and box installation, which is applied in the direction of coolers, electrical components, cooling fluid circulation devices, etc., and can solve problems such as forgetting to connect the connector, complicated operation, and narrow mechanical room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

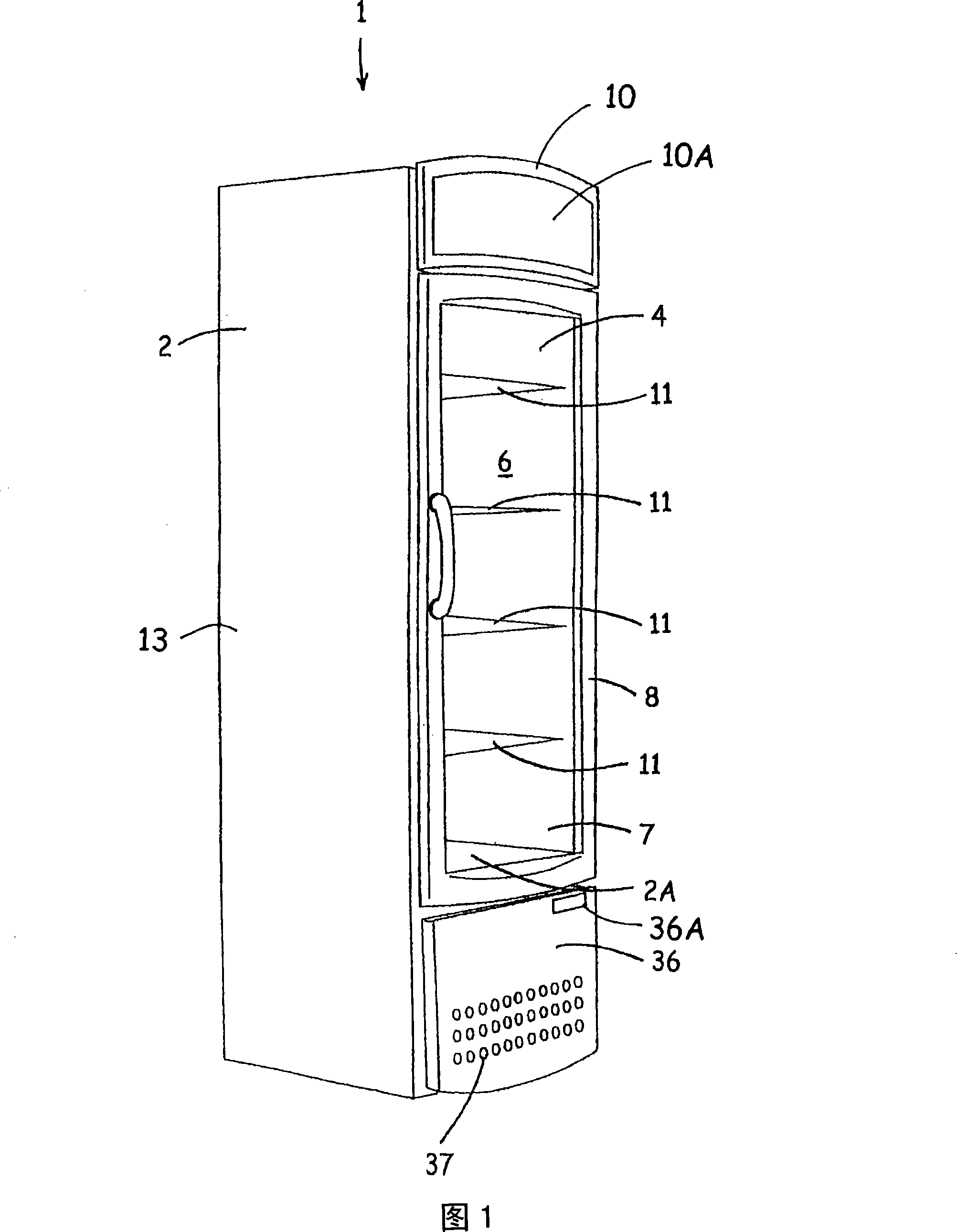

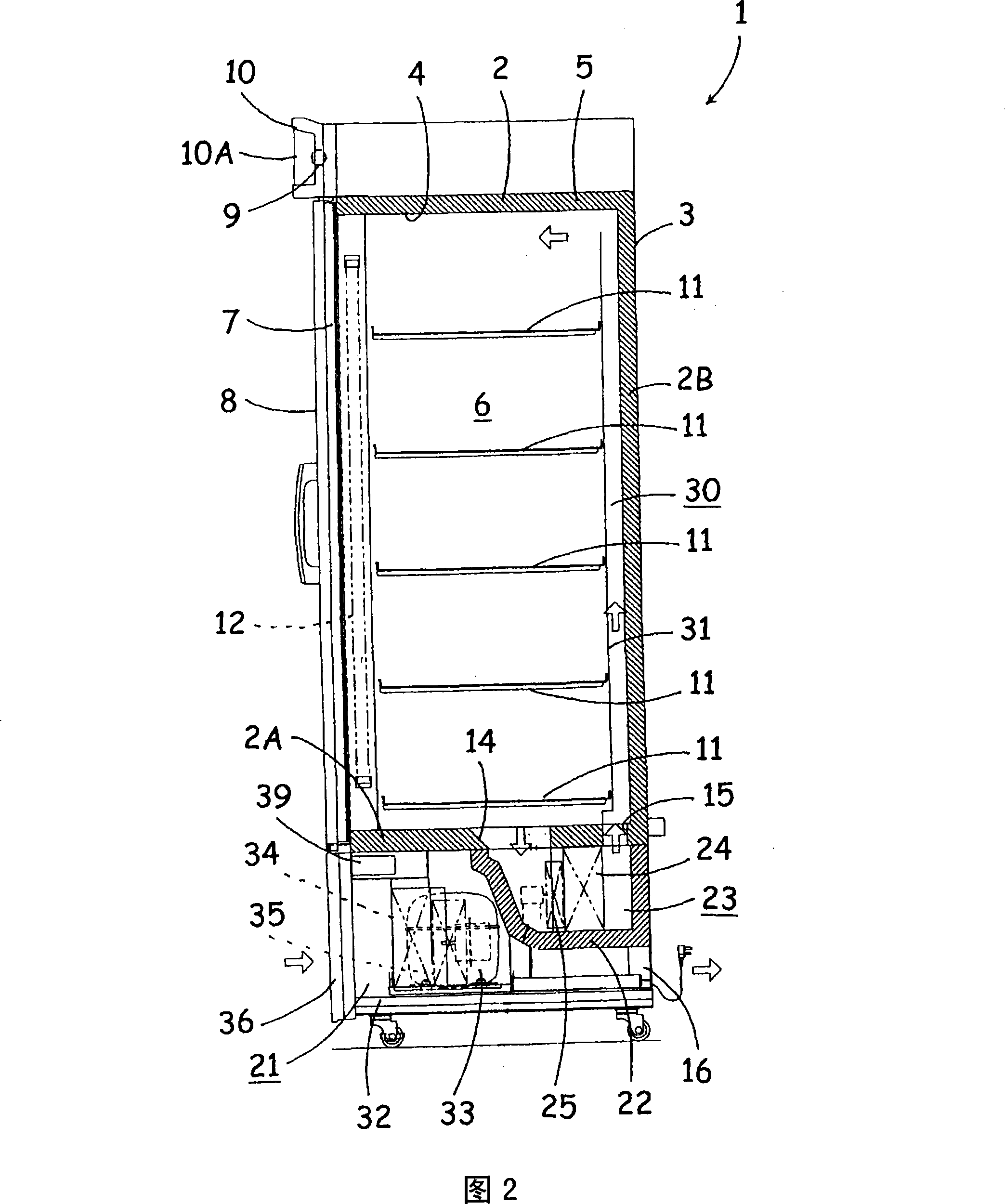

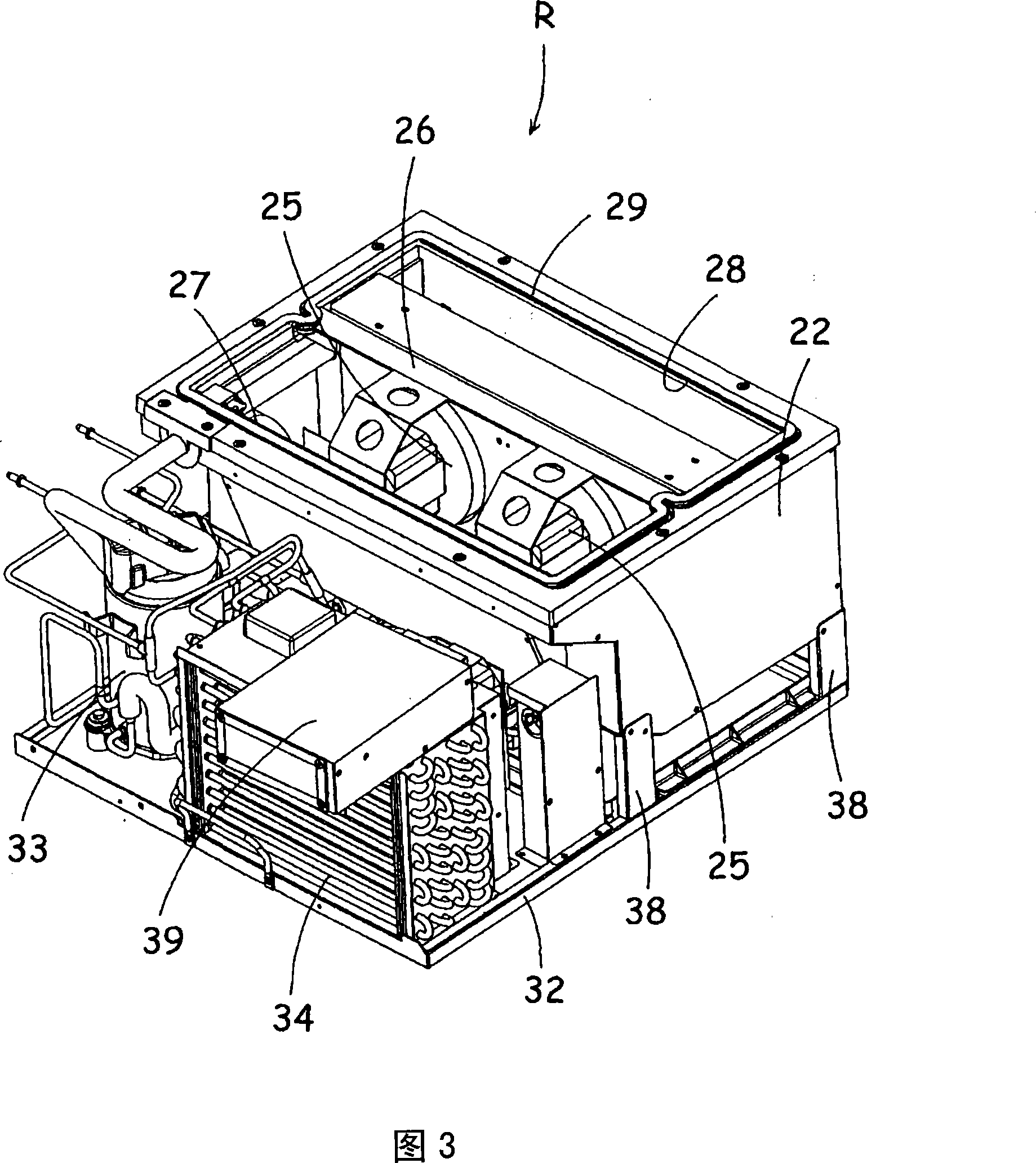

[0045] First, the cooling storage 1 provided with the electrical installation box 39 which is Example 1 is demonstrated, referring FIGS. 1-5. Fig. 1 shows the perspective view of the cooling storage room 1 to which the present invention is applied, Fig. 2 shows the longitudinal section side view of the same cooling storage room 1, Fig. 3 shows the perspective view of the cooling unit, Fig. 4 shows the side view of the cooling unit, and Fig. 5 shows the cooling unit. Perspective view of unit and lifting mechanism L.

[0046] The cooling storage 1 of the present embodiment has a main body constituted by a rectangular heat insulating box 2 opened at the front. The heat insulating box 2 includes: an outer box 3 made of steel plate having an opening at the front; an inner box 4 having an opening at the front; In addition, a store room 6 opening on the front is formed in the heat insulating box 2, and the front opening of the store room 6 is closed openably and closably by a door 8...

Embodiment 2

[0082] First, as a second embodiment, with reference to the partial enlarged cross-sectional views of FIGS. The holding structure in 52 is described. In addition, in each figure, the parts attached with the same symbols as those in Fig. 7 and Fig. 8 have the same mechanism and effect, so the description thereof will be omitted.

[0083] In the above-described embodiment, a flange portion 53 protruding outward toward the cover 42 is formed on the upper end of the coupler mounting member 50 , specifically, on the upper end of the sliding surface 50A. On the other hand, on the side surface of the cover 42 that slides on the sliding surface 50A, except for the above-mentioned engagement hole 42A, in the state where the coupler mounting member 50 is accommodated in the coupler accommodating part 44, the corresponding flange part 53 Engagement holes 54 , 55 are provided through the position corresponding to the flange portion 53 in a state where the coupler mounting member 50 is pu...

Embodiment 3

[0088] Next, as a third embodiment, with reference to the partially enlarged cross-sectional views of FIGS. Be explained. In addition, in each figure, the parts attached with the same symbols as those in Fig. 7 and Fig. 8 have the same mechanism and effect, so the description thereof will be omitted.

[0089] In the above-described embodiment, the protrusion 57 protruding outward toward the cover 42 is formed on the upper end of the coupler mounting member 50 , specifically, on the sliding surface 50A. On the other hand, on the side surface of the cover 42 that slides on the sliding surface 50A, except for the above-mentioned engagement hole 42A, when the coupler mounting member 50 is accommodated in the coupler accommodating portion 44, the position corresponding to the protruding portion 57 , and in the state where the coupler mounting member 50 is pulled out from the coupler accommodating portion 44 to be exposed, engagement holes 58 , 59 are respectively penetrated at pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com