Electric resistance measuring device and method for tire

一种电阻测定、测定装置的技术,应用在测量装置、轮胎零部件、测量电阻/电抗/阻抗等方向,能够解决很长时间等问题,达到维持测定精度、简化测定作业、保证导电性性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

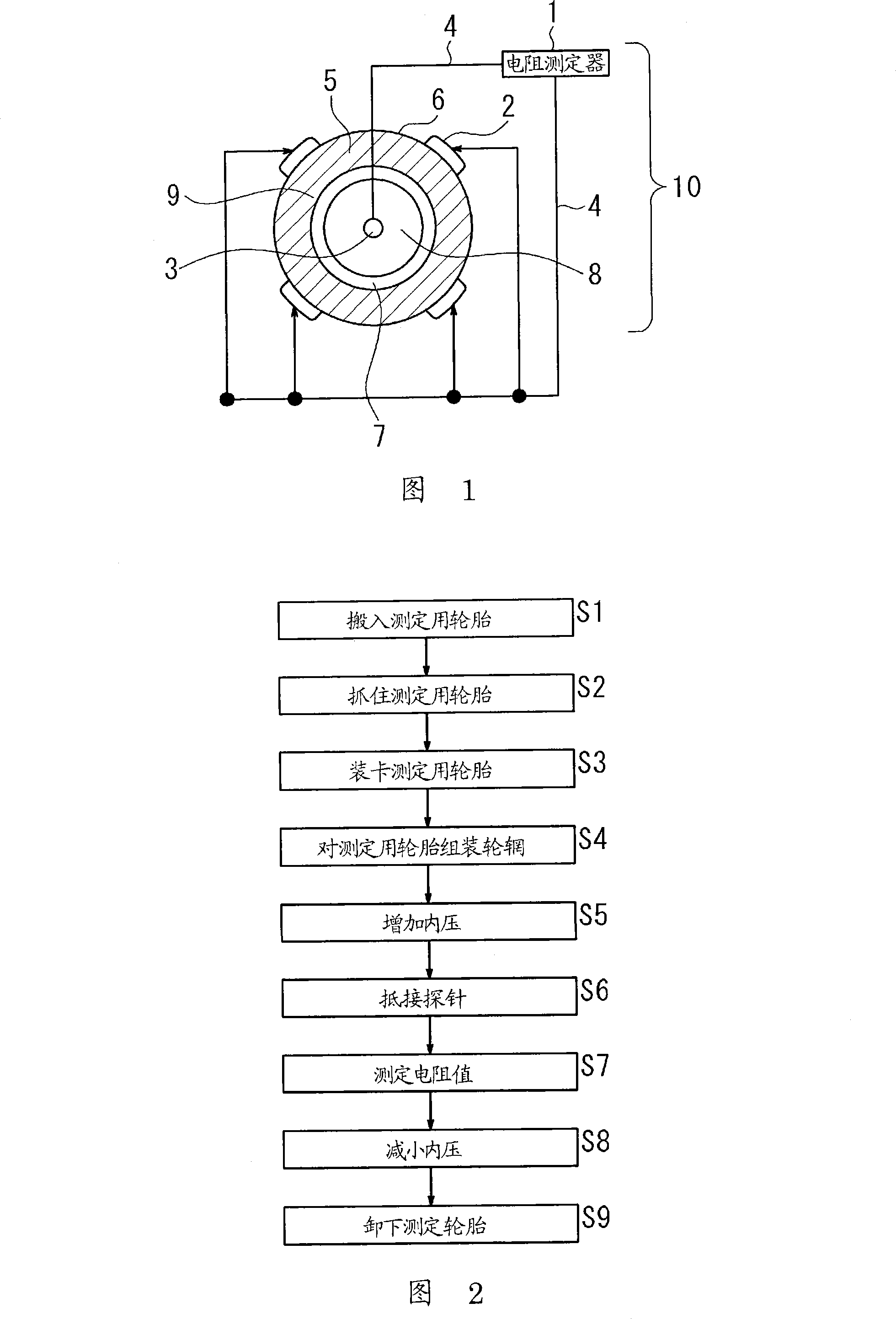

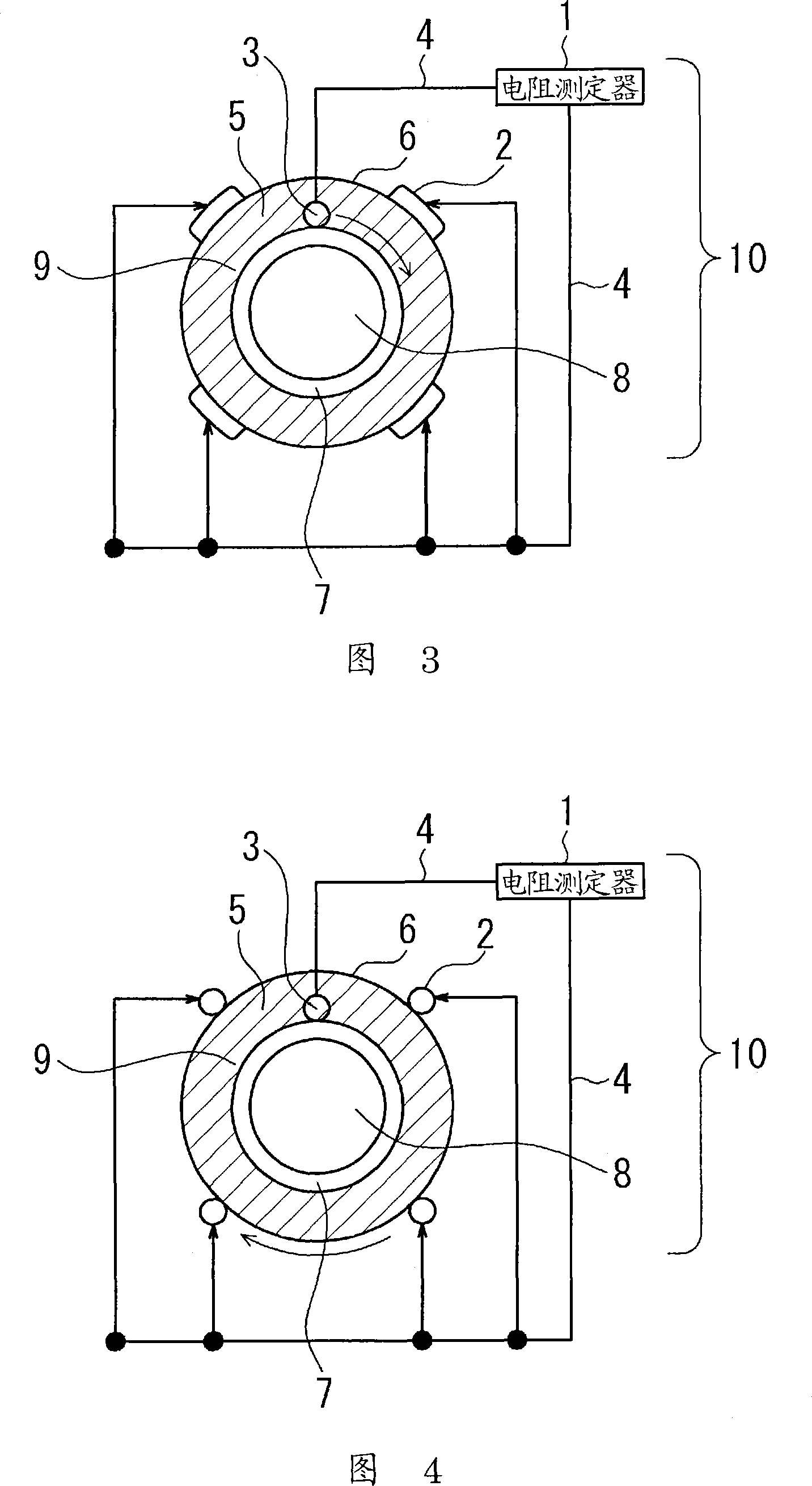

[0048] The steps of measuring the resistance value of the tire 5 in the second embodiment are only different from the first embodiment in the two working steps S6 and S7 shown in the first embodiment, and the other working steps are the same as in the first embodiment, so the descriptions are omitted. Description of other job steps. The four first probes 2 are brought into contact with the central part of the width of the tire 5 (the width of the tread portion 6) that divides the tread outer peripheral surface of the tire 5 into four equal parts, and then the second probes 2 mounted on the rotating member are The probe 3 is in contact with the side wall surface of the bead portion 9 (S6), and while the resistance measuring device 1 is powered on, the second probe 3 is rotated once to measure the distance between the tread portion 6 and the bead portion 9. between the resistance value (S7).

[0049] A conceptual diagram showing the overall configuration of a third embodiment o...

no. 3 Embodiment approach

[0050] The steps of measuring the resistance value of the tire 5 in the third embodiment are only different from the first embodiment in the two operation steps S6 and S7 shown in the first embodiment, and the other operation steps are the same as in the first embodiment, therefore, the descriptions are omitted. Description of other job steps. Four columnar first probes 2 are brought into contact with the central part of the width of the tire 5 (the width of the tread portion 6 ) that divides the outer peripheral surface of the tread portion 6 of the tire 5 into four equal parts, and then mounted on a normal The second probe 3 on the gripping member of the first contact with the side wall surface of the bead portion 9 (S6), while turning on the power of the resistance measuring device 1, rotate the tire 5 to be measured by a normal rotating member for a while, While measuring the resistance value between the tread portion 6 and the bead portion 9 (S7). In addition, the reason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com