Displacement sensor testing frock of electrohydraulic servo valve

A technology of displacement sensors and electro-hydraulic servo valves, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. The effect of development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

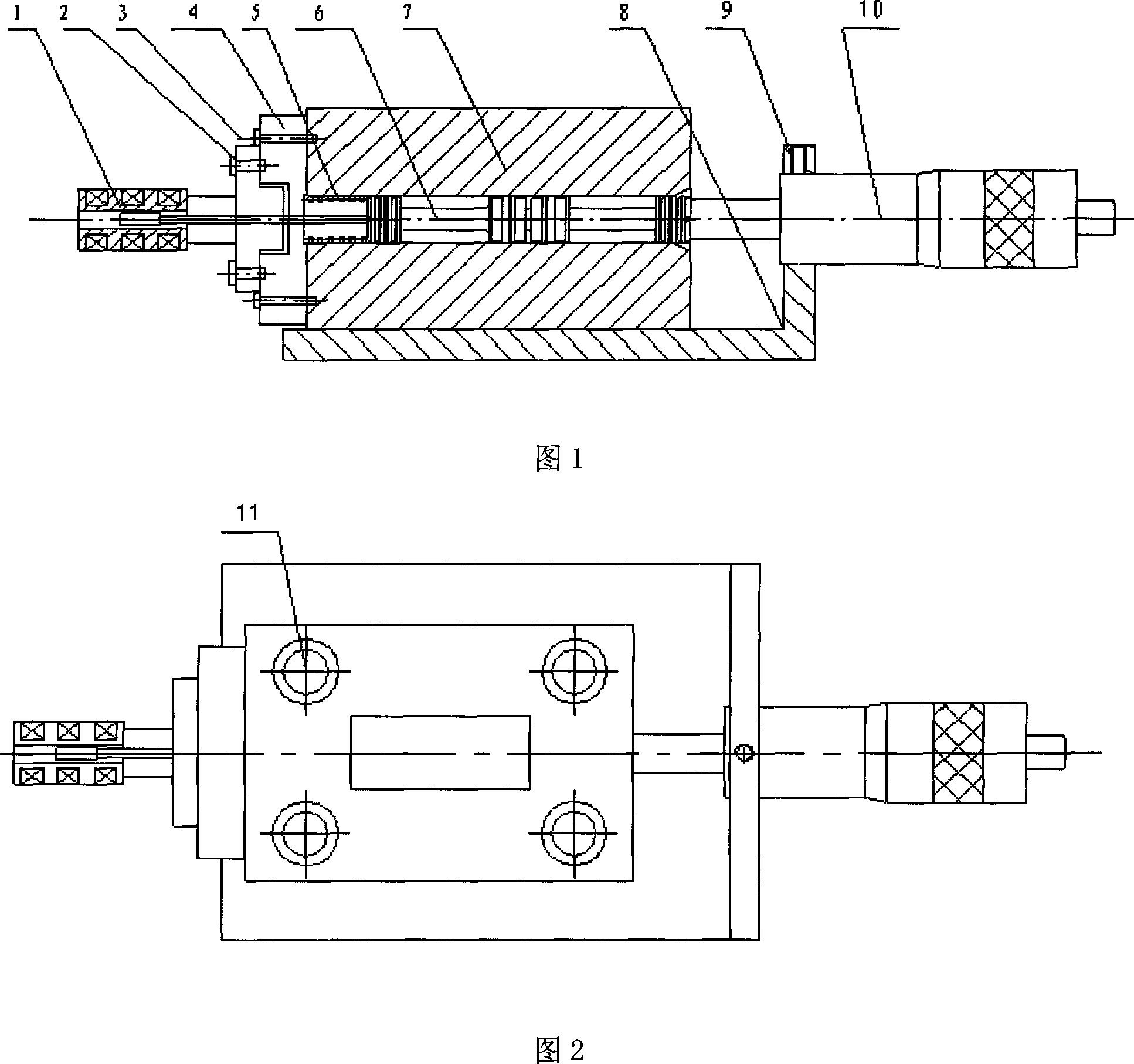

[0014] As shown in Figure 1, a displacement sensor test tool for electro-hydraulic servo valves, including valve core test seat 7, handle micrometer 10, iron core rod sleeve 6 and displacement sensor fixed end cover 4, the iron core The rod sleeve 6 is installed in the valve core test seat 7, one end of which is equipped with a return spring 5, and a stainless steel rod sleeve is installed on its outer sea, and the end cover 4 is connected to the iron core rod sleeve 6 and the displacement sensor coil 1 by screws 2 and 3 , the screw micrometer head 10 is positioned and fixed by the screw 9, and the valve core test seat 7 is fixed on the valve core test seat 8 by the screw 11; the displacement sensor coil 1 is externally connected with a built-in amplifier (input excitation signal, output secondary Coil excitation signal), the screw micrometer head 10 feeds (or retreats), so that the core rod sleeve 6 is displaced, and the secondary coil generates a voltage difference, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com