Centrifugal type coffee machine

A coffee machine and centrifugal technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of no coffee taste, bland and tasteless coffee, etc., and achieve the effect of strong aroma and prolonged contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

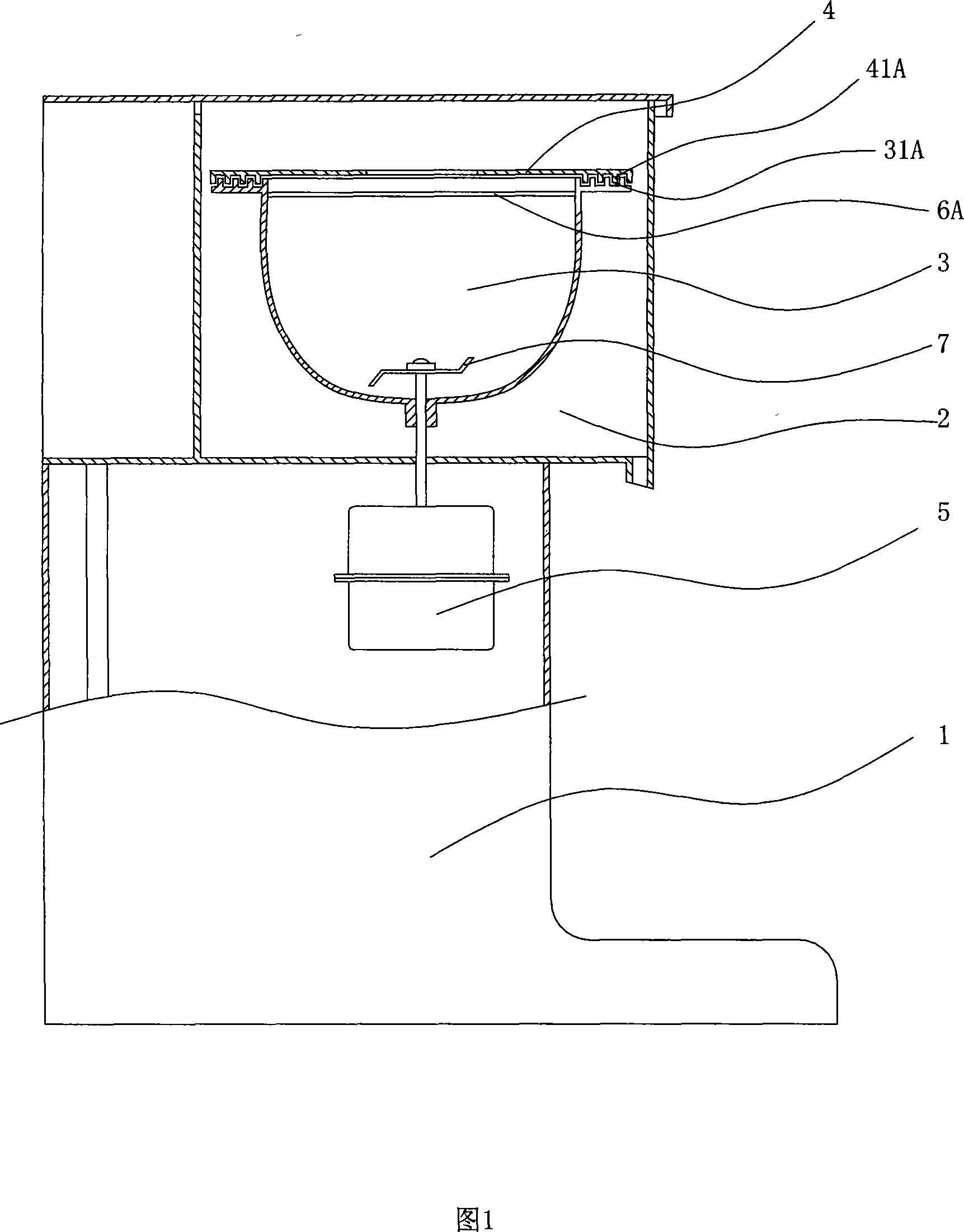

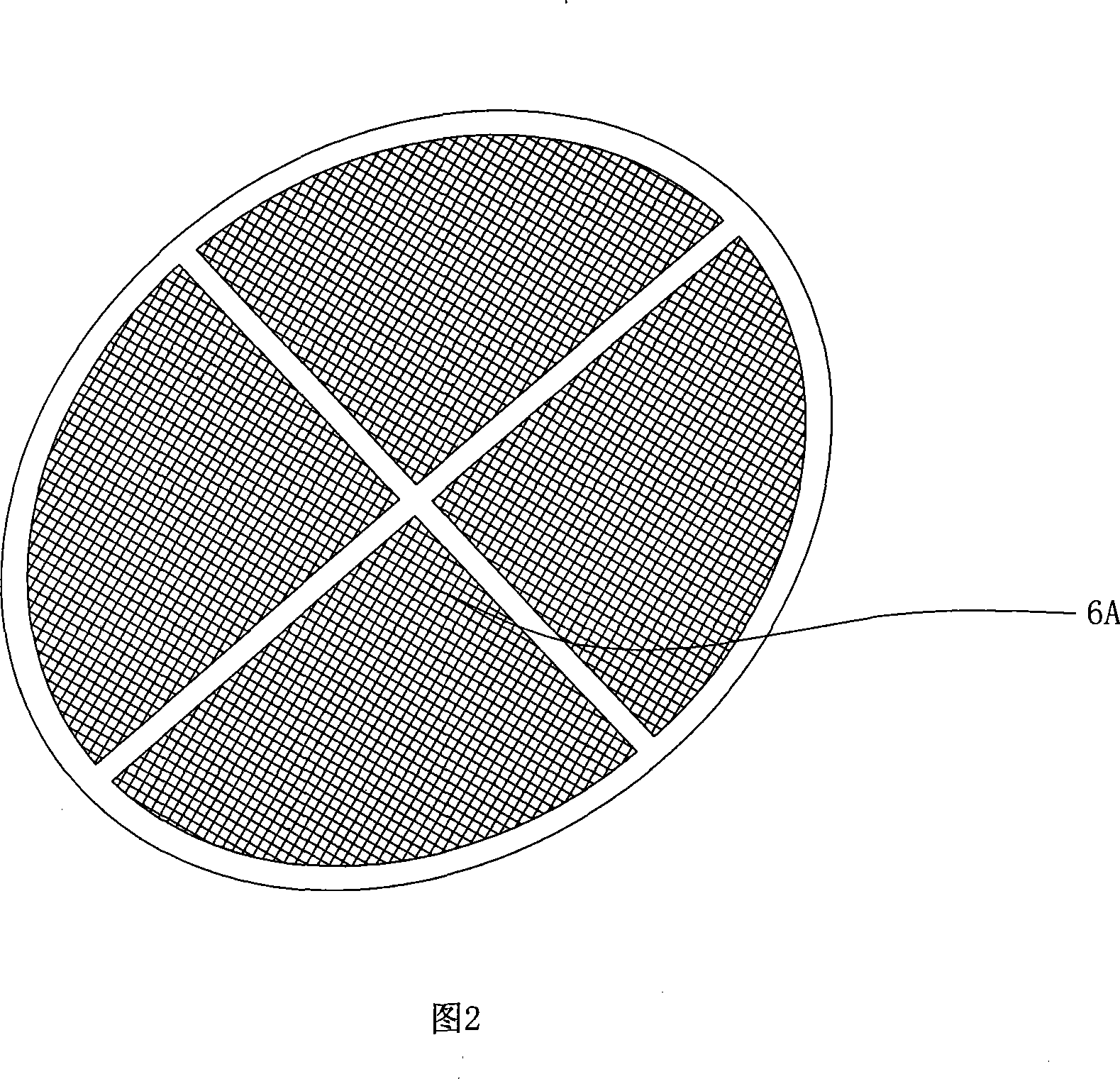

[0014] As shown in Figures 1 and 2, a centrifugal coffee machine according to the first embodiment of the present invention includes a base 1, a coffee liquid collection chamber 2, a funnel 3, a funnel cover 4 and a motor 5; the funnel 3 is located in the collection chamber 2 Inside, the motor 5 is fixed in the base 1, and the motor 5 can drive the funnel 3 to rotate. Several grooves 31A of the funnel 3 and several bumps 41A of the funnel cover 4 are matched to form a coffee liquid damping channel; the upper part of the funnel 3 is open A filter screen 6A is arranged at the place; a blade 7 for grinding coffee beans is arranged at the bottom. The coffee liquid in the funnel 3 flows into the coffee liquid damping channel after passing through the filter screen 6A under the action of centrifugal force, and finally enters the coffee liquid collecting chamber 2 .

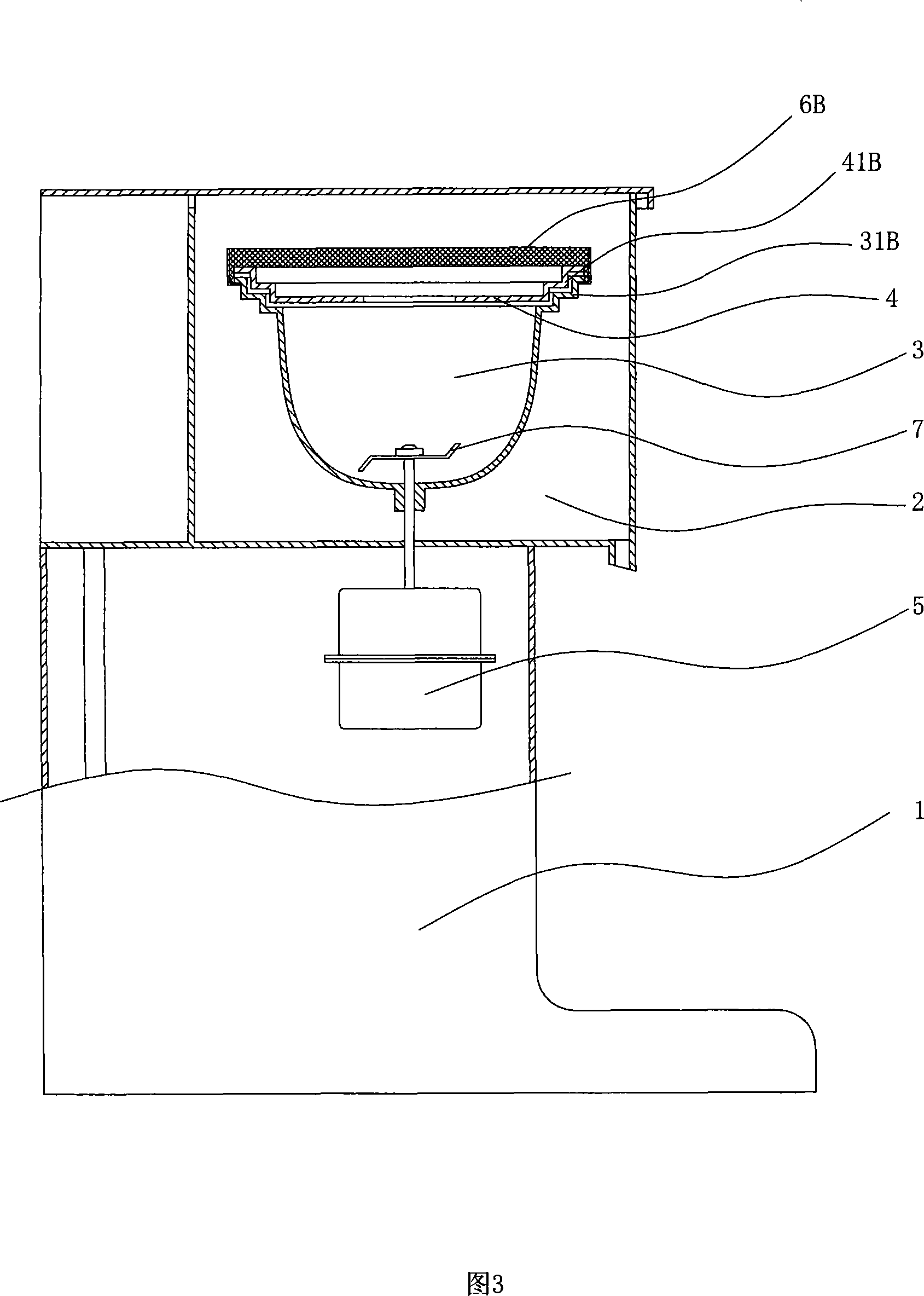

[0015] As shown in Figure 3; a centrifugal coffee machine according to the second embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com