Ring shaped radial arrayed fluidized bed membrane reactor

A membrane reactor, radial technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor heat transfer effect, unsuitable for small-scale distributed hydrogen production, and bulky reactors, etc., to achieve Easy to install arranged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with examples and drawings, but the embodiments of the present invention are not limited to this.

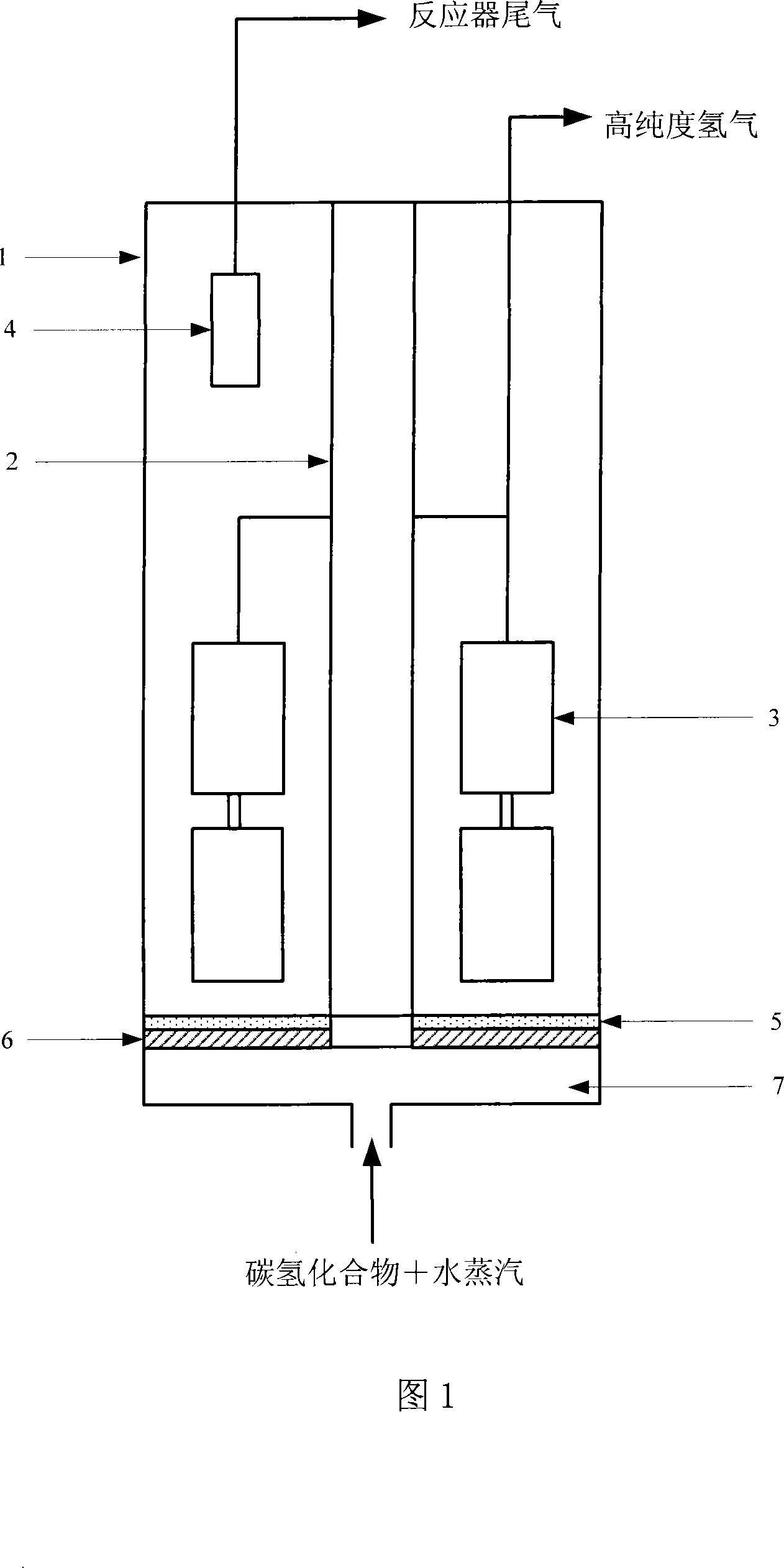

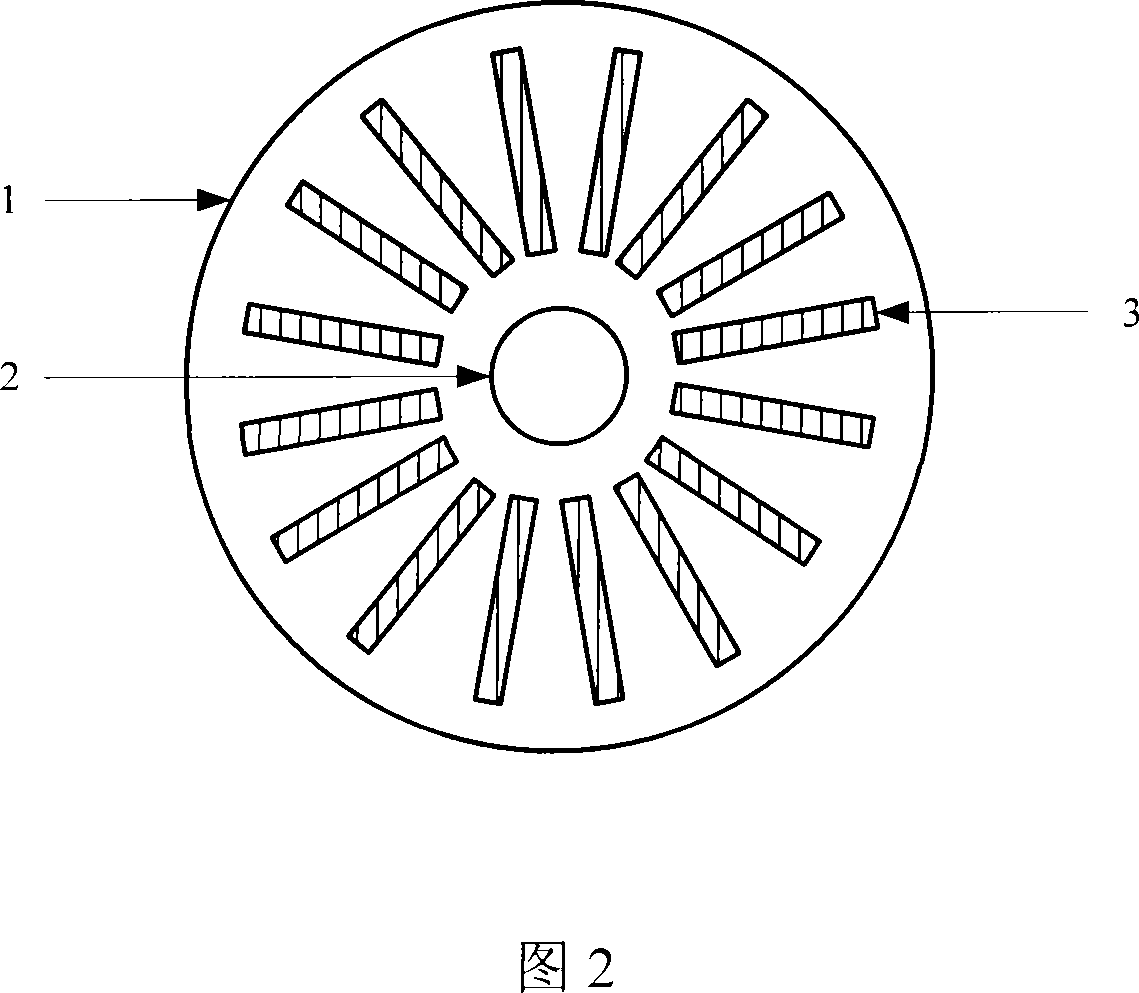

[0022] As shown in Figures 1 and 2, a ring-shaped radially arranged fluidized bed membrane reactor includes a ring-shaped including an outer tube 1, an inner tube 2, a palladium membrane module 3, an exhaust gas filter 4, and a feed air distribution plate 5. , The support plate 6 and the wind box 7; the inner tube 2 is located in the center of the outer tube 1, the outer tube 1 forms the outer wall of the reactor, the inner tube 2 forms the inner wall of the reactor, the annular space is formed between the inner and outer tubes, and a plurality of palladium membrane modules 3 The annular space between the inner tube and the outer tube is arranged radially. Both sides of each membrane module are covered with palladium-silver alloy membranes. The pure hydrogen side of all palladium membrane modules is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com