High speed full automatic paper bowl and paper cup shaping machine

A fully automatic, forming machine technology, applied in the direction of cardboard winding articles, etc., can solve the problems of low positioning accuracy of the turntable, poor pressing and forming effect, difficult alignment of stations, etc. The effect of weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

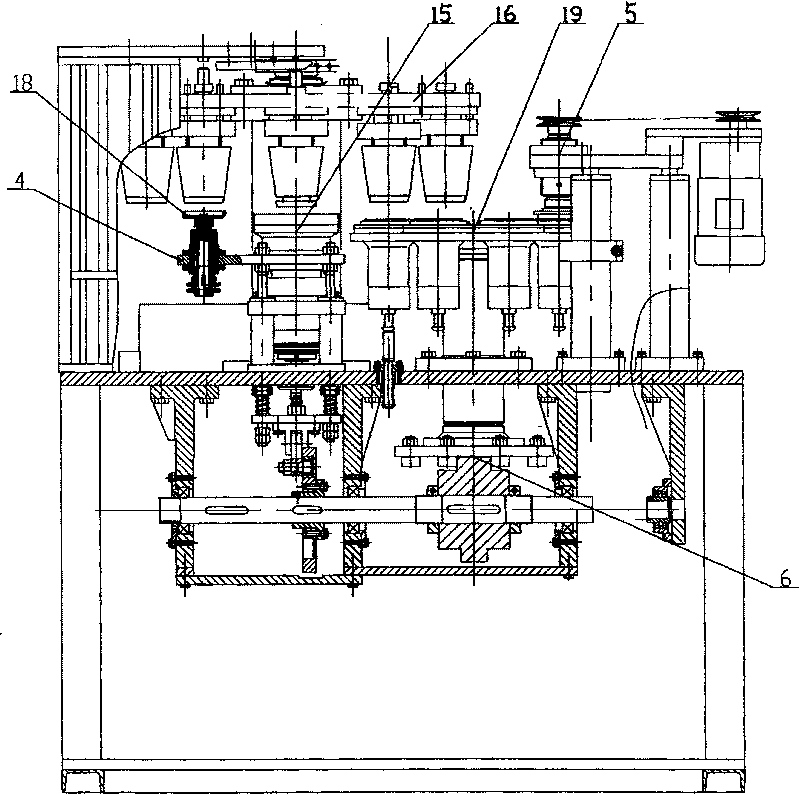

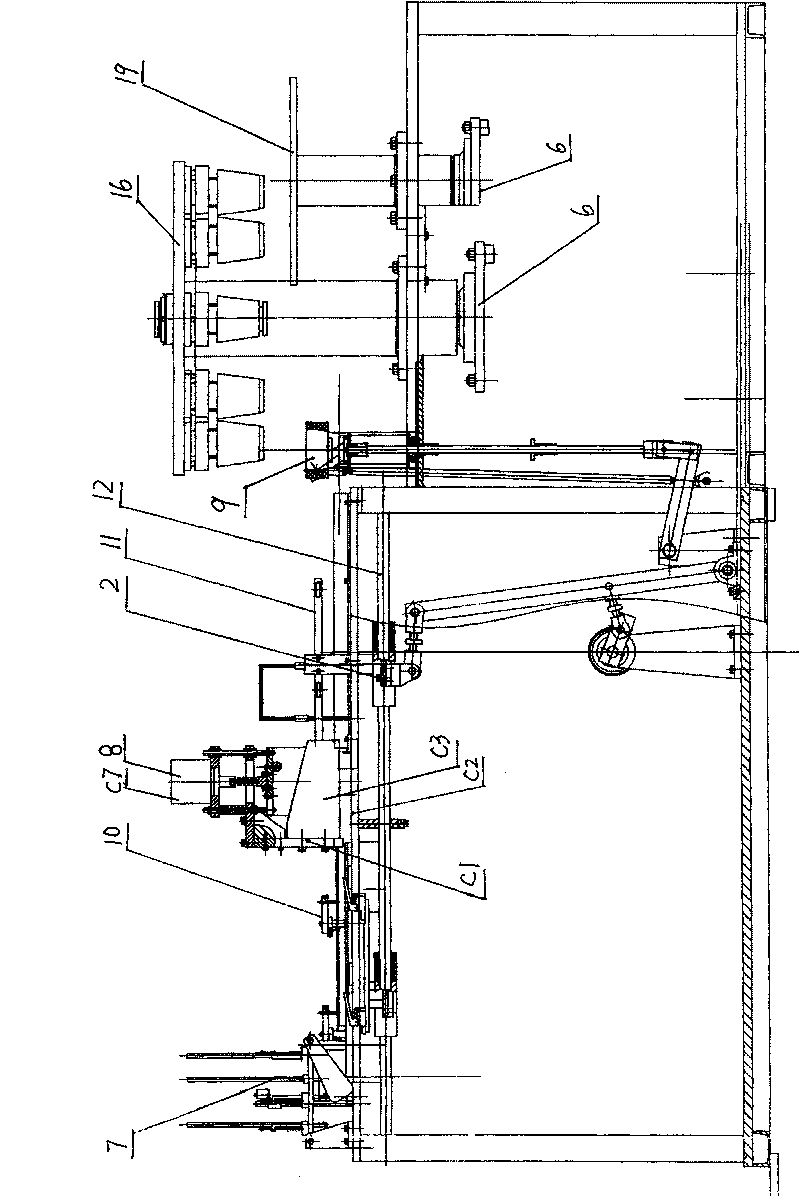

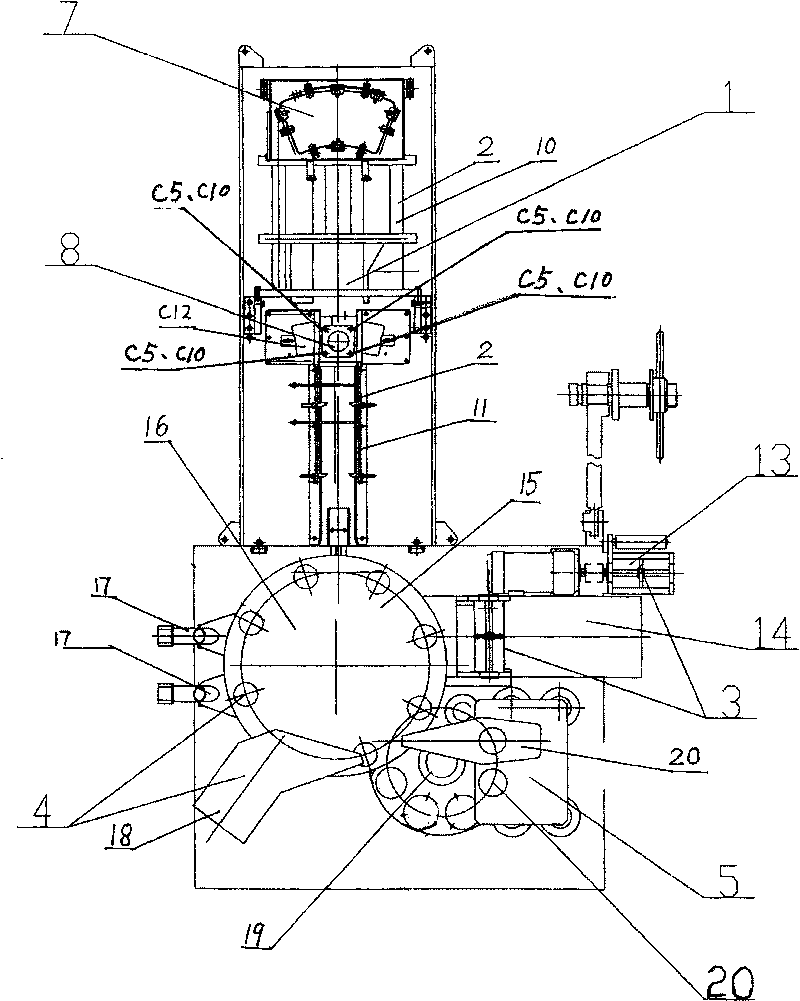

[0026] Such as figure 1 , figure 2 , image 3 The high-speed automatic paper cup forming machine shown includes: a fan forming mechanism (1) connected to a conveying mechanism (2), a cup bottom paper punching mechanism (3) connected to a cup bottom forming mechanism (4), a cup bottom forming mechanism (4) ) is connected to the cup opening forming mechanism (5), and the cup bottom forming mechanism (4) and the cup opening forming mechanism (5) are connected to the turntable indexing mechanism (6).

[0027] 1. When the machine is running, the paper is loaded into the paper take-up mechanism (7), and is transported to the leaf wrapping mechanism (8) by the paper translation mechanism (10) in the conveying mechanism (2) to wrap it into a paper tube. 2. The cup turning mechanism (9) is installed after the paper tube conveying mechanism (11). The cup turning mechanism (9) is close to the first turntable (16), and the paper cup is sent to the Enter the cup-turning mechanism (9), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com