Half-penetration and reflection type liquid crystal panel

A semi-transmissive reflection and liquid crystal panel technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of increasing the number of drive components, reducing process yield, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

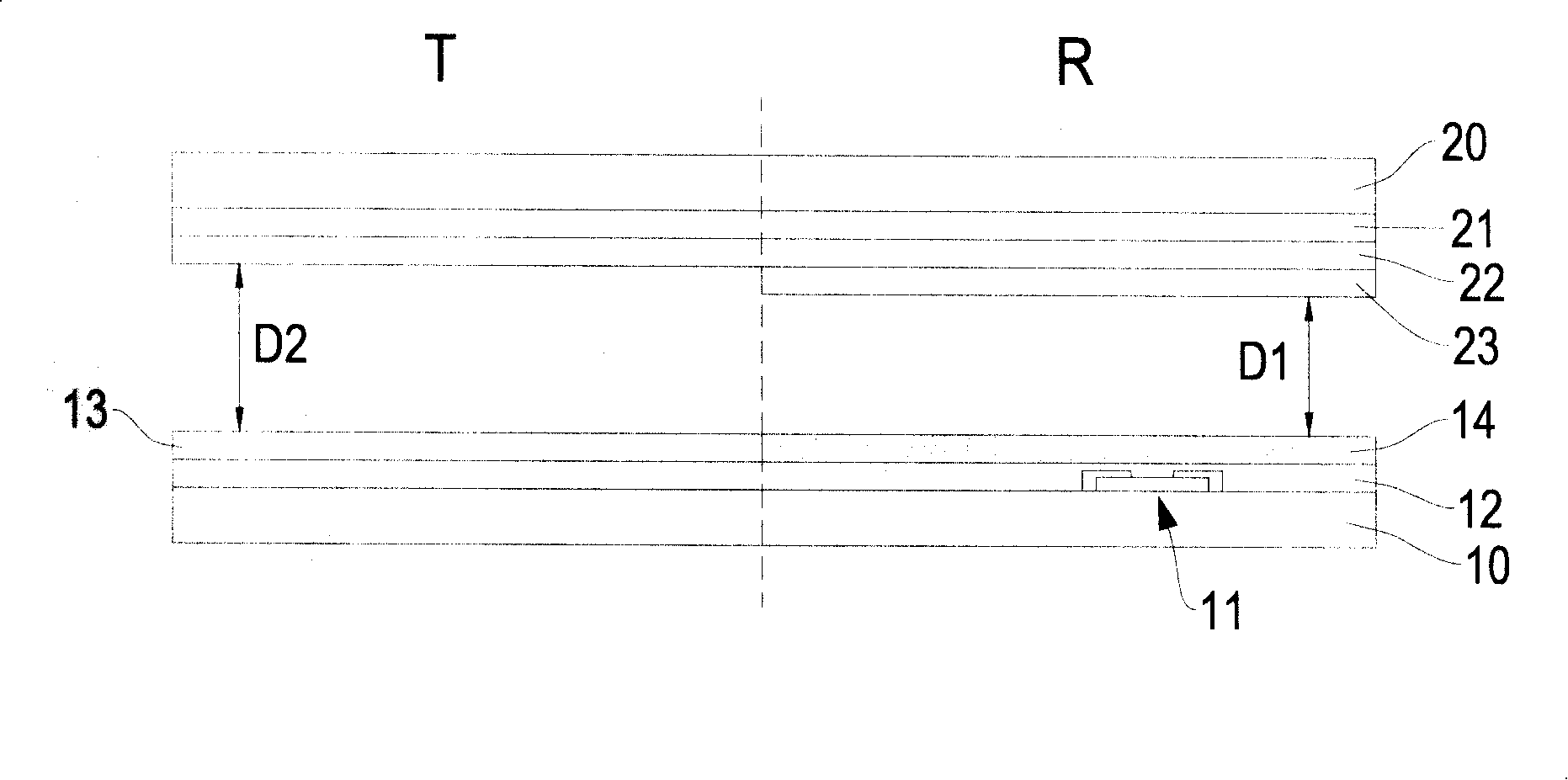

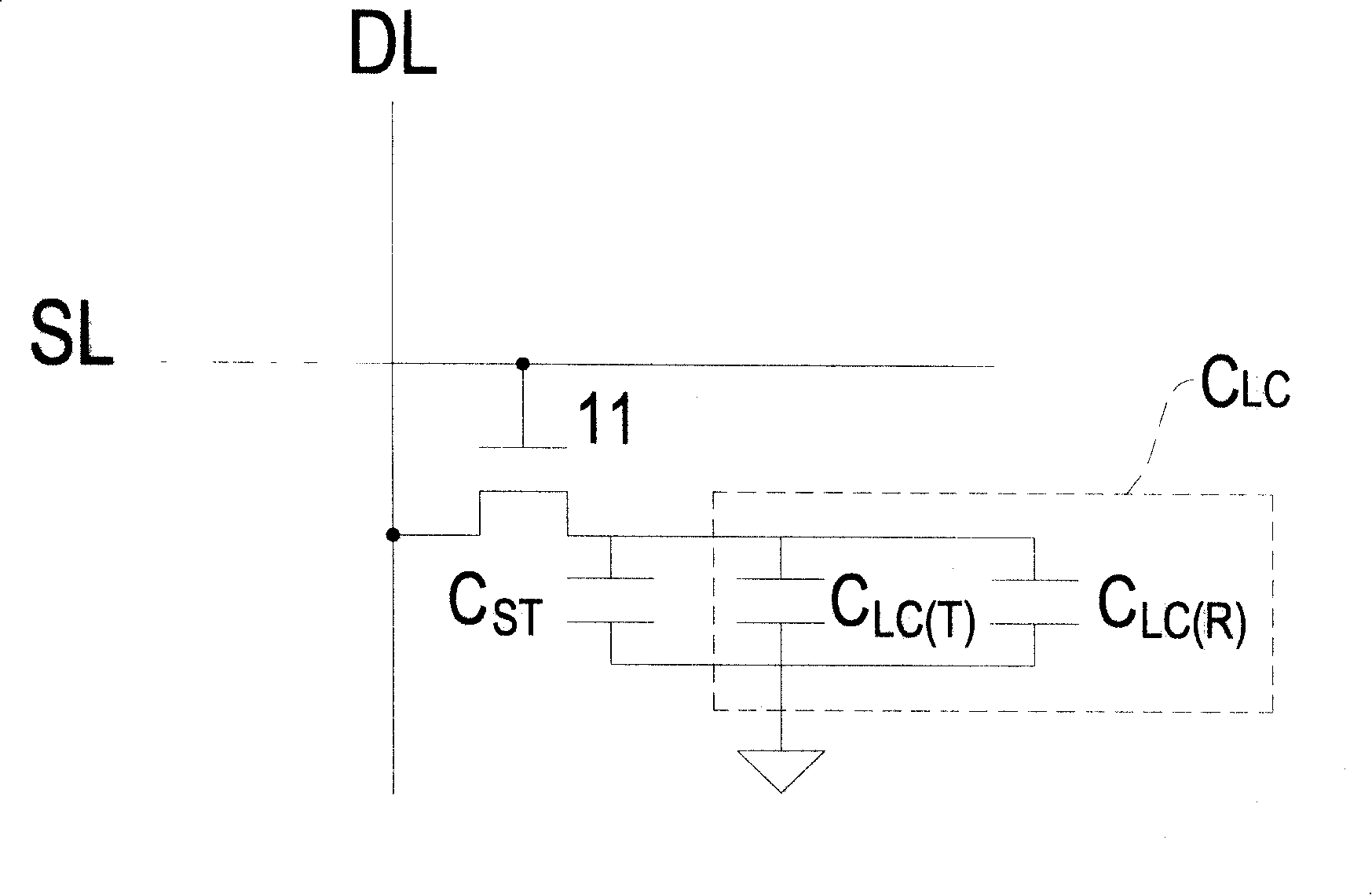

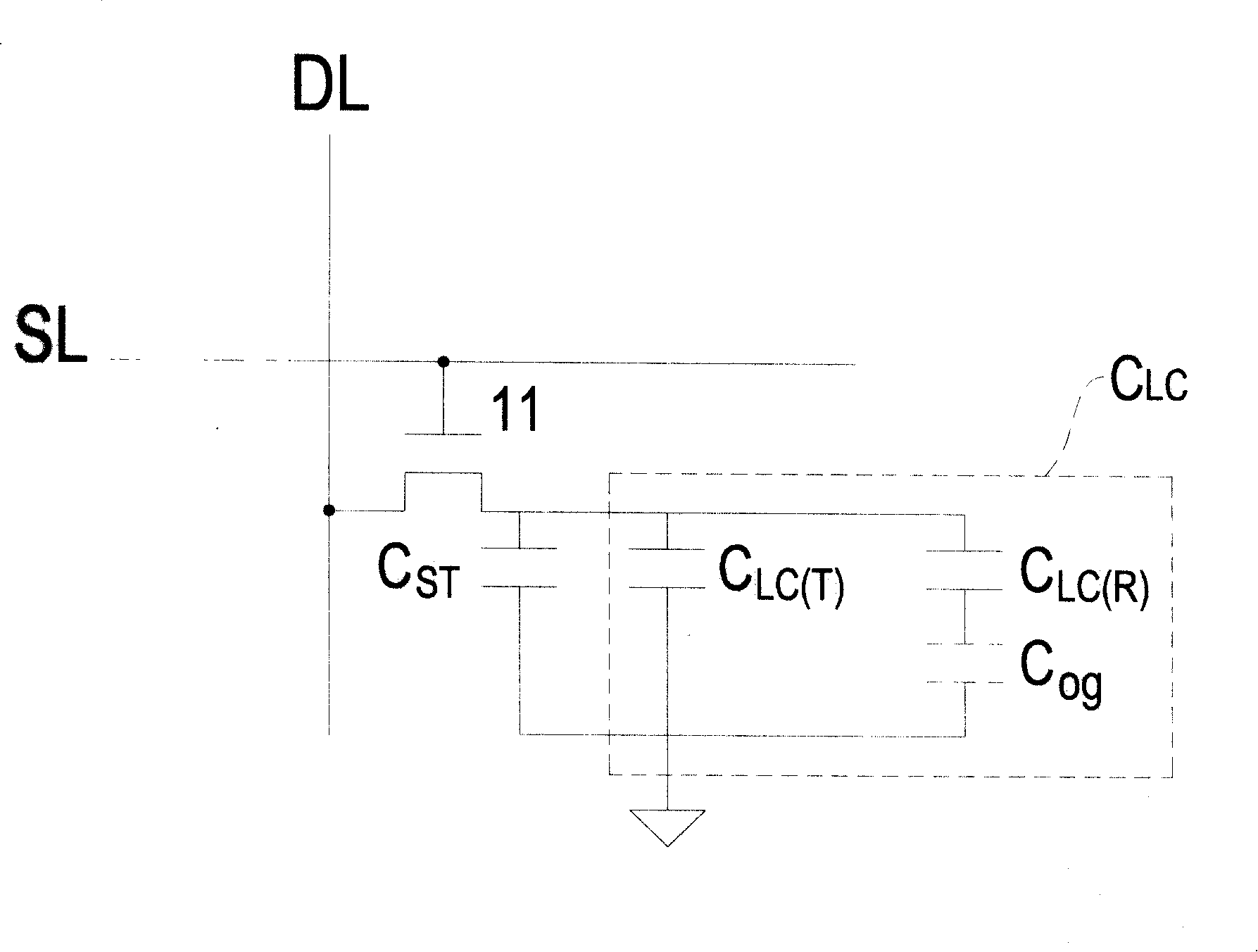

[0031] Regarding the specific implementation manner of the present invention, one of its preferred embodiments is as follows figure 1 As shown, the schematic structure of half of the transflective liquid crystal panel is disclosed in the figure, mainly to form a proper distance (cell gap) between the first substrate (10) and the second substrate (20) which are arranged oppositely, for filling Liquid crystal, to constitute the liquid crystal layer; wherein:

[0032] On one surface of the first substrate (10), at least a plurality of thin film transistors (11) and a plurality of storage capacitors, scanning lines and data lines not shown in the figure are formed, and arranged in a matrix to define a multi-pixel unit; Also the upper layer of the aforementioned components is formed with a protective layer (12), and a pixel electrode (13) (ITO) and a reflective layer (14) are respectively formed on the protective layer (12) at each pixel unit position, and the reflective layer (14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com