Method for producing joint of spectacle and joint of spectacle produced therefrom

A technology of glasses and production steps, which is applied in the field of production of glasses joints, can solve the problems of production reduction, destruction, and discarding in manufacturing factories, and achieve the effect of reducing processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

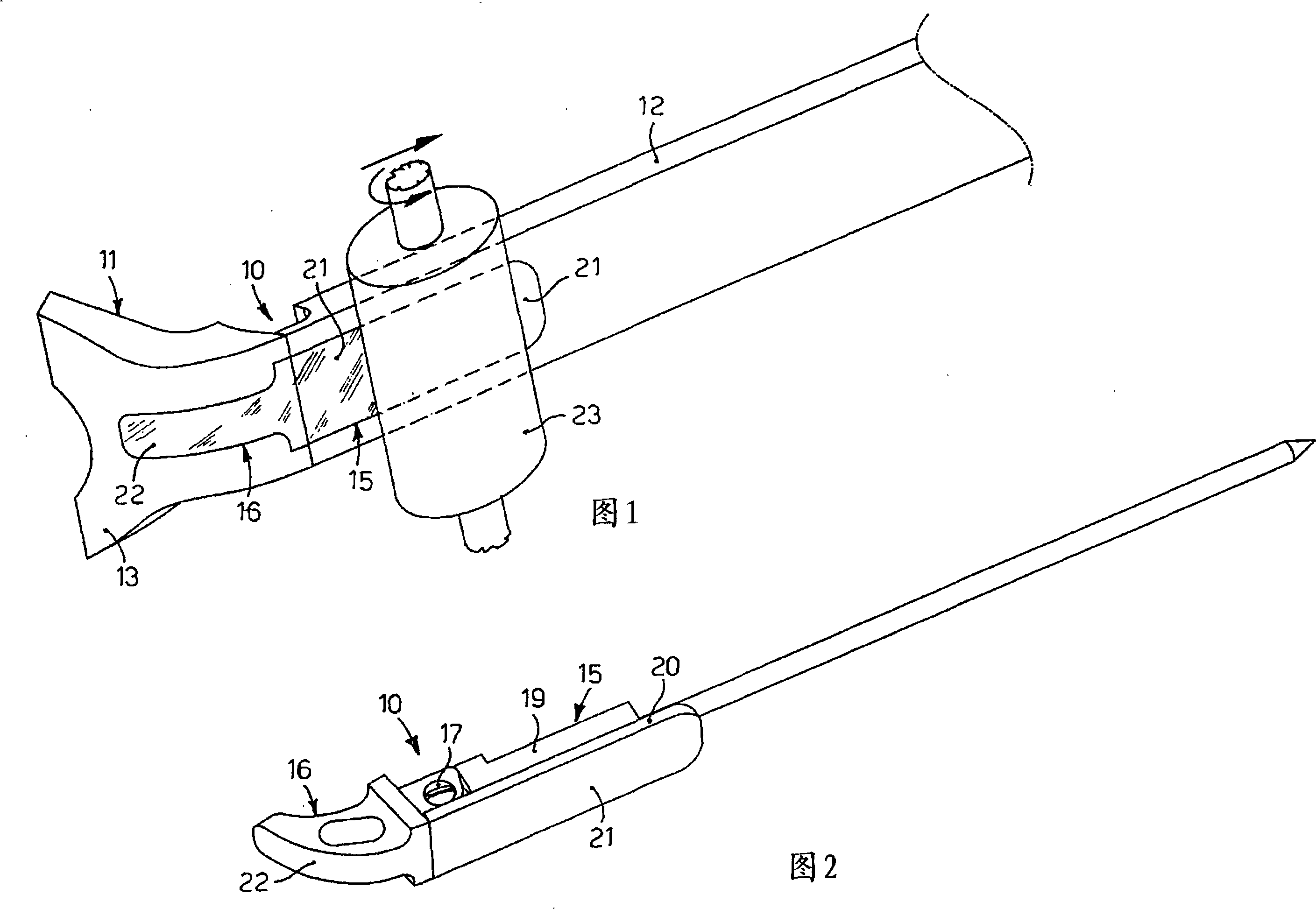

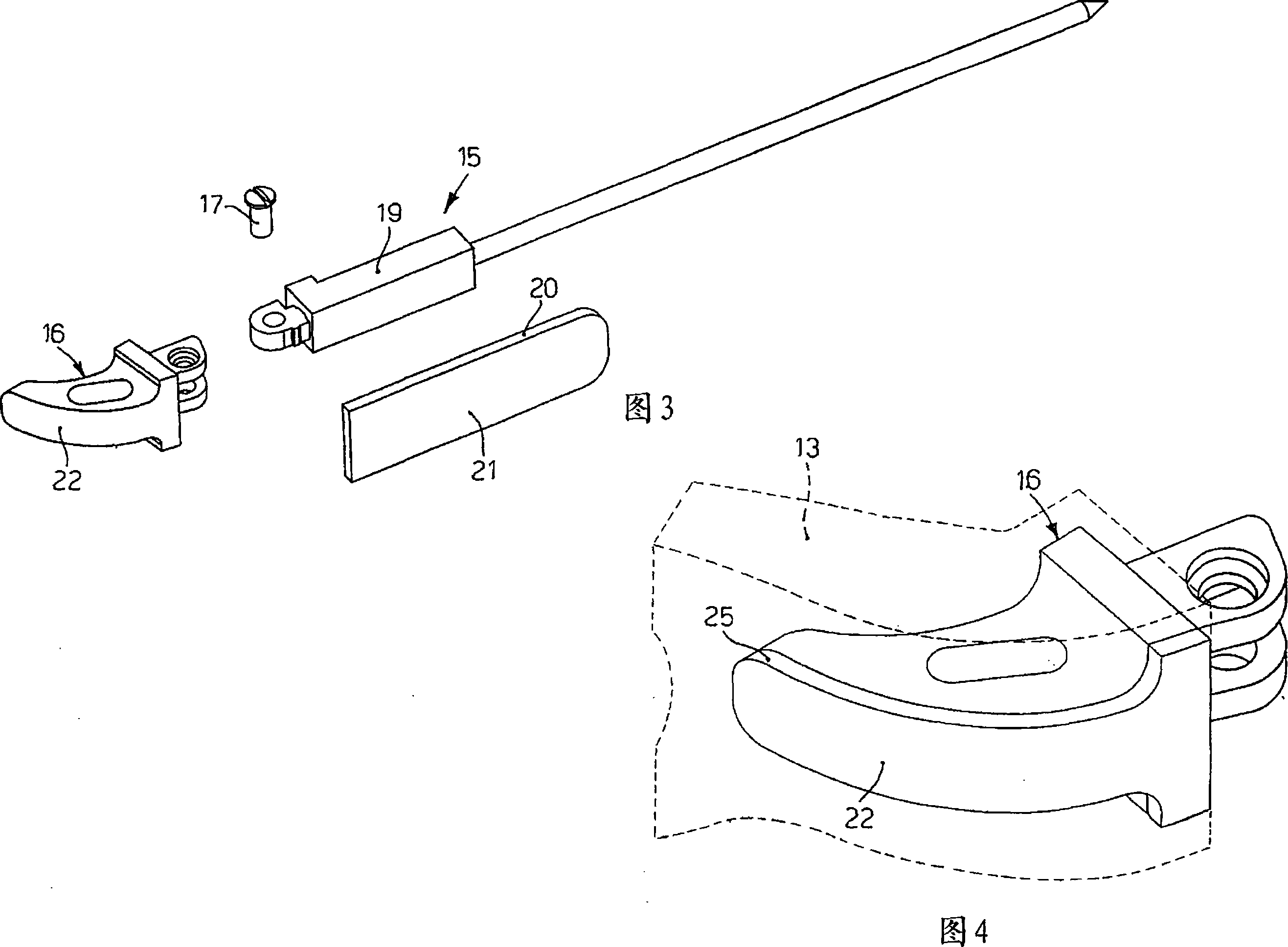

[0028] With reference to the accompanying drawings, a joint 10 according to the invention is applied for relative articulation between the side 12 and the flange 13 of the spectacle frame 11, allowing the side 12 to be selectively positioned in an open position for use and a closed position for non-use between positions.

[0029] In particular, the joint 10 according to the invention comprises two articulation elements in a conventional manner, respectively a first element 15 associated with the side 12 and a second element 16 associated with the flange 13, and the two articulation elements are passed through The pins 17 - in this case screws - pivot relative to each other.

[0030] Specifically as shown in Figures 2 and 3, the joint 10 also includes a small plate 20 and a box-shaped body 19 welded to the small plate 20, and at least one elastic member not shown in the figure is arranged inside the joint to allow The additional movement of the side part 12 with the required e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com