Two freedom mobile parallel connection mechanism with buffering ability

A technology with cushioning capacity and degrees of freedom, applied in the field of two-degree-of-freedom mobile parallel mechanisms, can solve the problems of poor mechanical stress, non-conforming stiffness, and poor anti-vibration performance, and achieve the effects of easy control, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

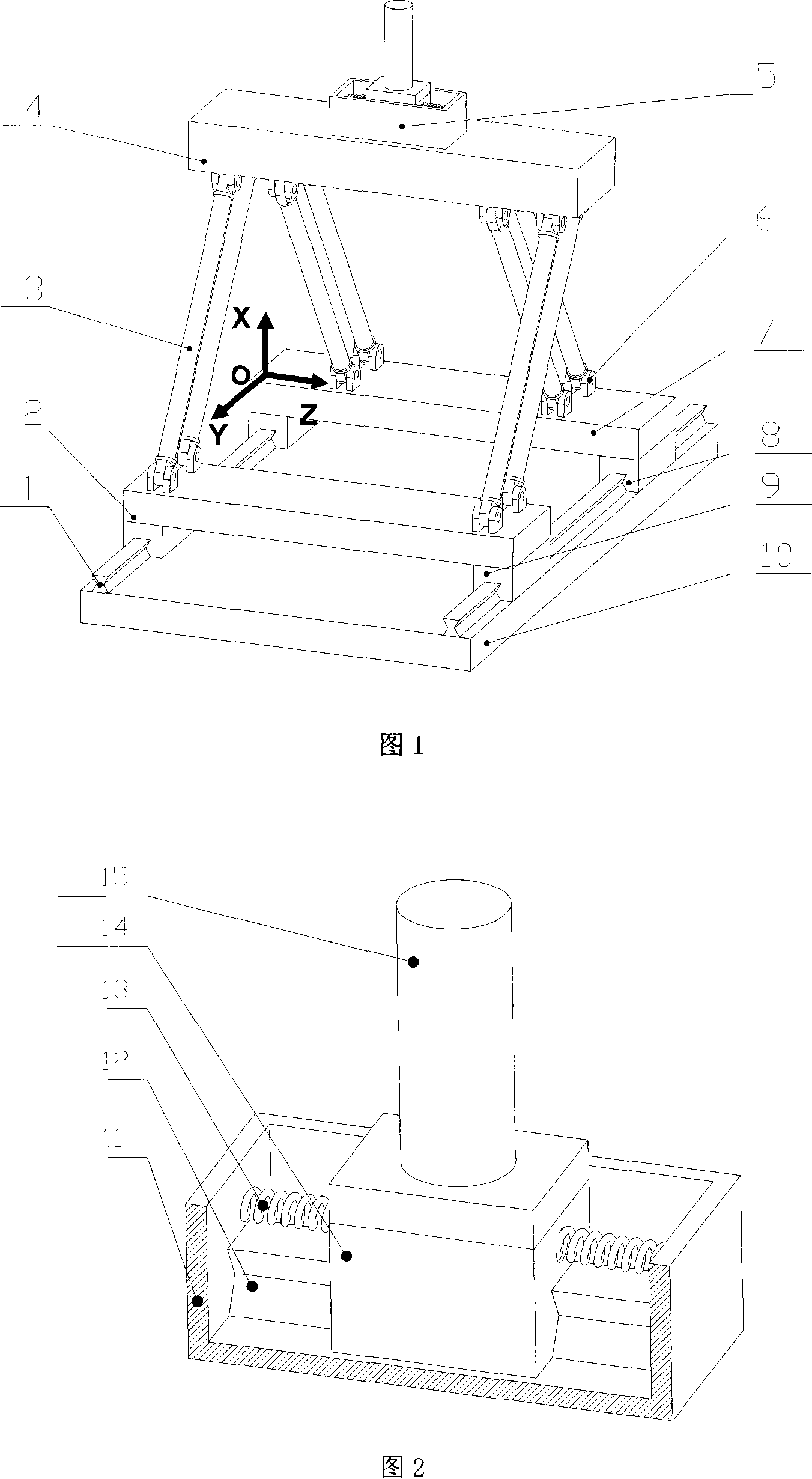

[0016] Embodiment 1: Fig. 1 shows a typical implementation of the present invention, which can realize two-degree-of-freedom movement in the plane, and also has a certain buffering ability and centering ability in the direction perpendicular to the plane.

[0017] As shown in Figure 1-2, this embodiment includes the following components: 1- guide rail, 2- sliding support on the lower left side, 3- supporting rod, 4- moving platform, 5- buffer device and end effector, 6- rotating pair , 7-sliding support on the lower right side, 8-right sliding block, 9-left sliding block, 10-basic platform. The overall mechanism is fixed on the corresponding base platform 10 through the guide rail 1, the left slider 9 and the right slider 8 are fixed on the guide rail 1, and the two lower sliding supports 2 and 7 respectively fix the corresponding left slider 9, The right side slider 8, while the moving platform 4 is connected with the two lower side sliding supports 2 and 7 through a parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com