Shaping device for optical glass preform

A technology for optical glass and preforms, which can be used in glass forming, glass pressing, glass manufacturing equipment, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Before presenting a detailed description, it is noted that in the following description, similar components are denoted by the same numerals.

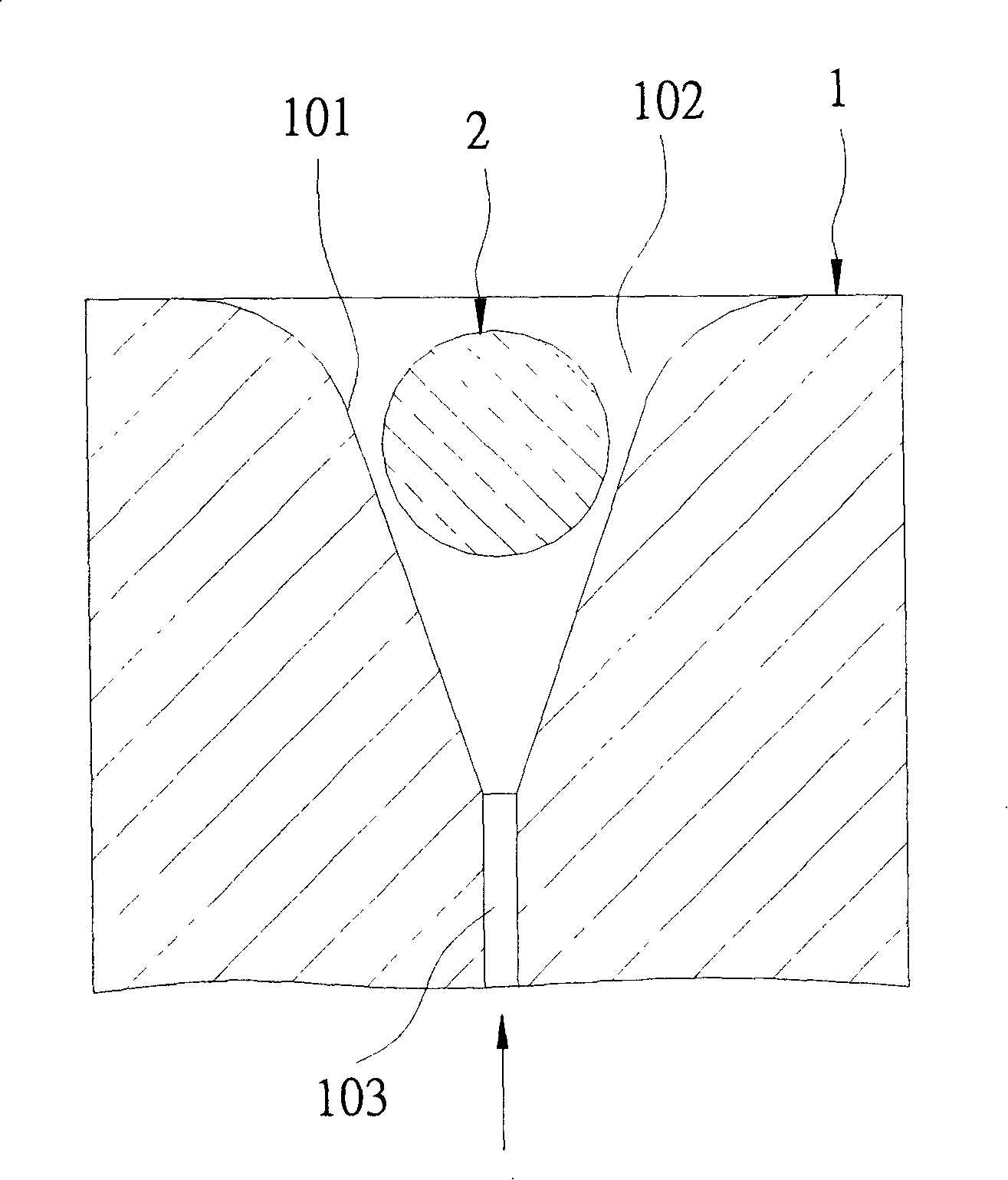

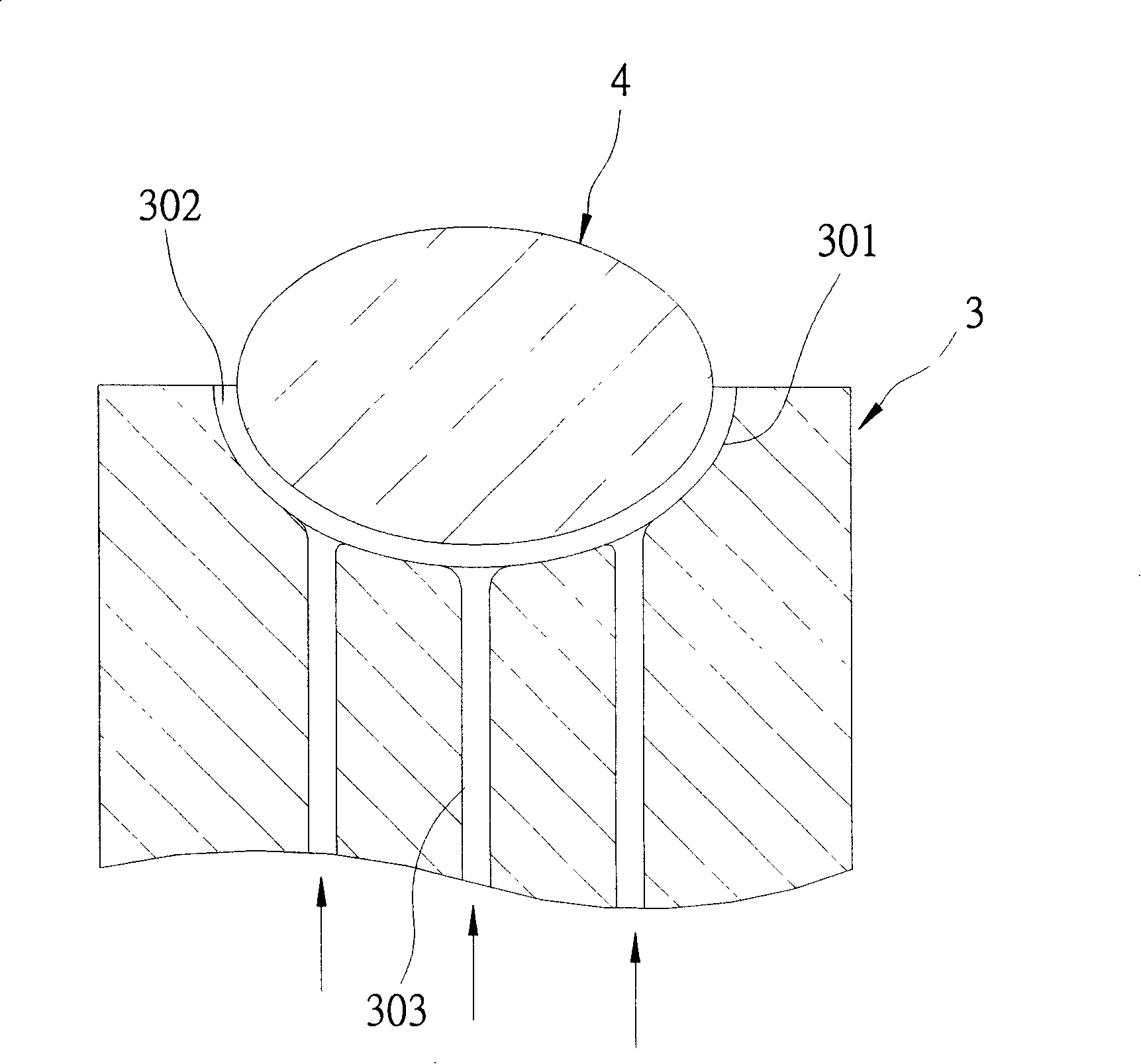

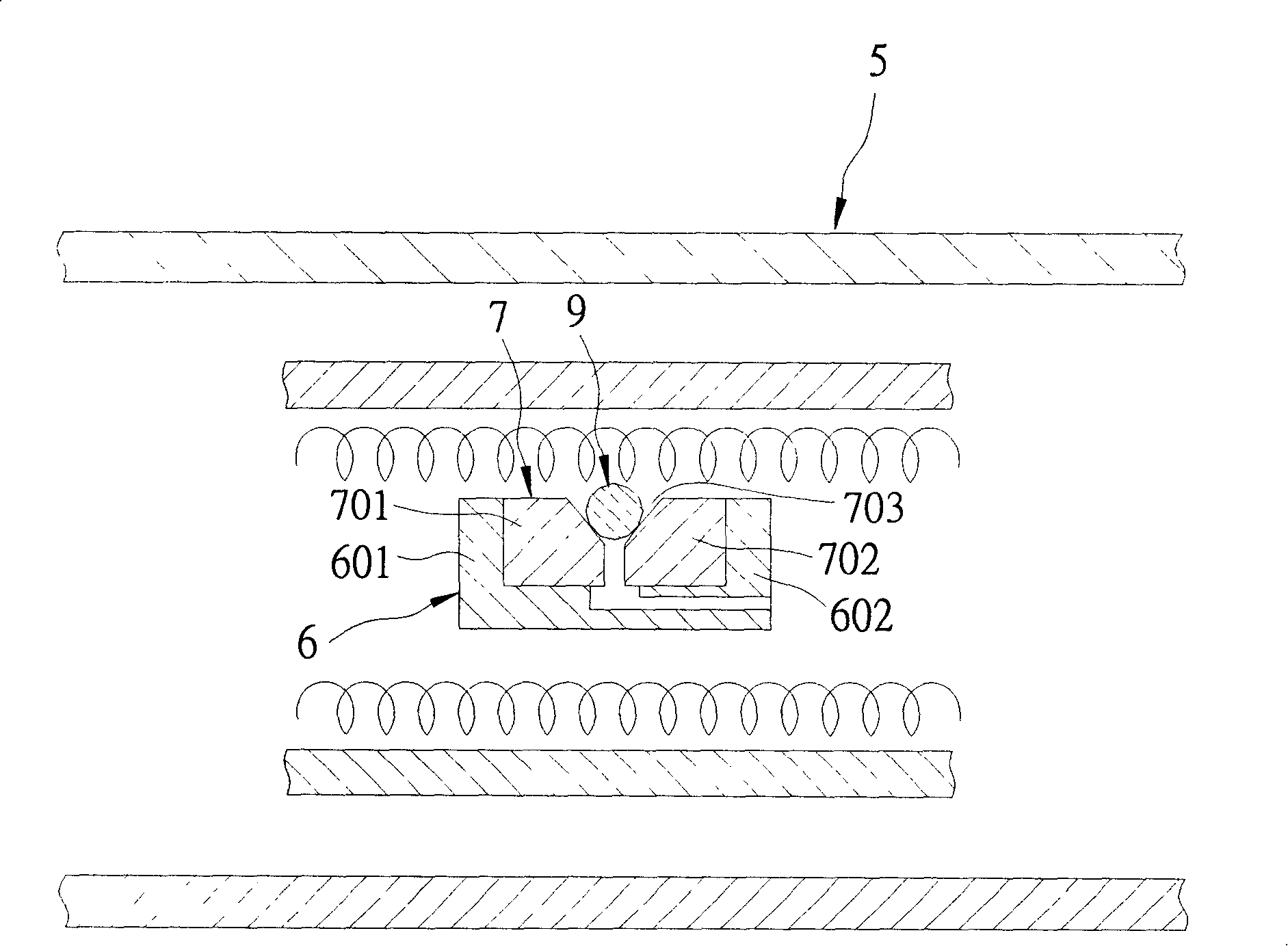

[0024] Referring to Fig. 5, 6, 7, a first preferred embodiment of the optical glass preform forming device of the present invention can be connected with a gas supply pipe 100 of an air pressure source (not shown), so that one from a platinum A molten glass 210 dripped from the outlet pipe 200 is formed into a spherical glass preform 220 with an outer diameter D. The forming device includes: a mold base 10 and a carrier 20 .

[0025] The mold base 10 has an upper mold body 11, a lower mold body 12 opposite to the upper mold body 11, an operating hole surface 13 around an axial direction X, and an operating hole defined by the operating hole surface 13. 14, and an air supply space 15 that surrounds the axial direction X and can communicate with the working hole 14 and the air supply pipe 100 of the air pressure source.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com