Blender arm and food processor

A technology of food processing and agitator, applied in mixers with rotating agitating devices, chemical instruments and methods, transportation and packaging, etc., can solve problems such as danger, achieve rapid cleaning, and reduce the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

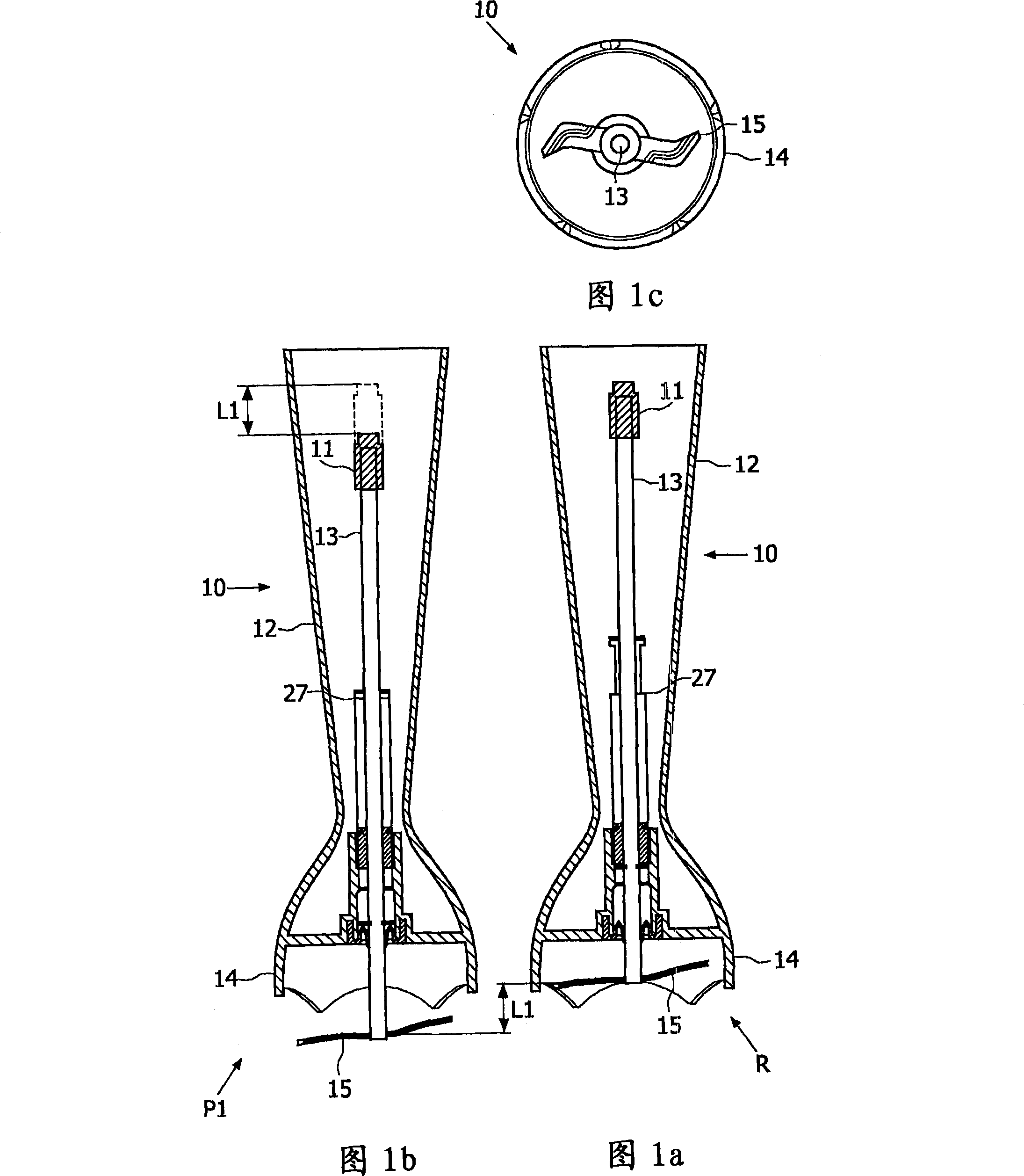

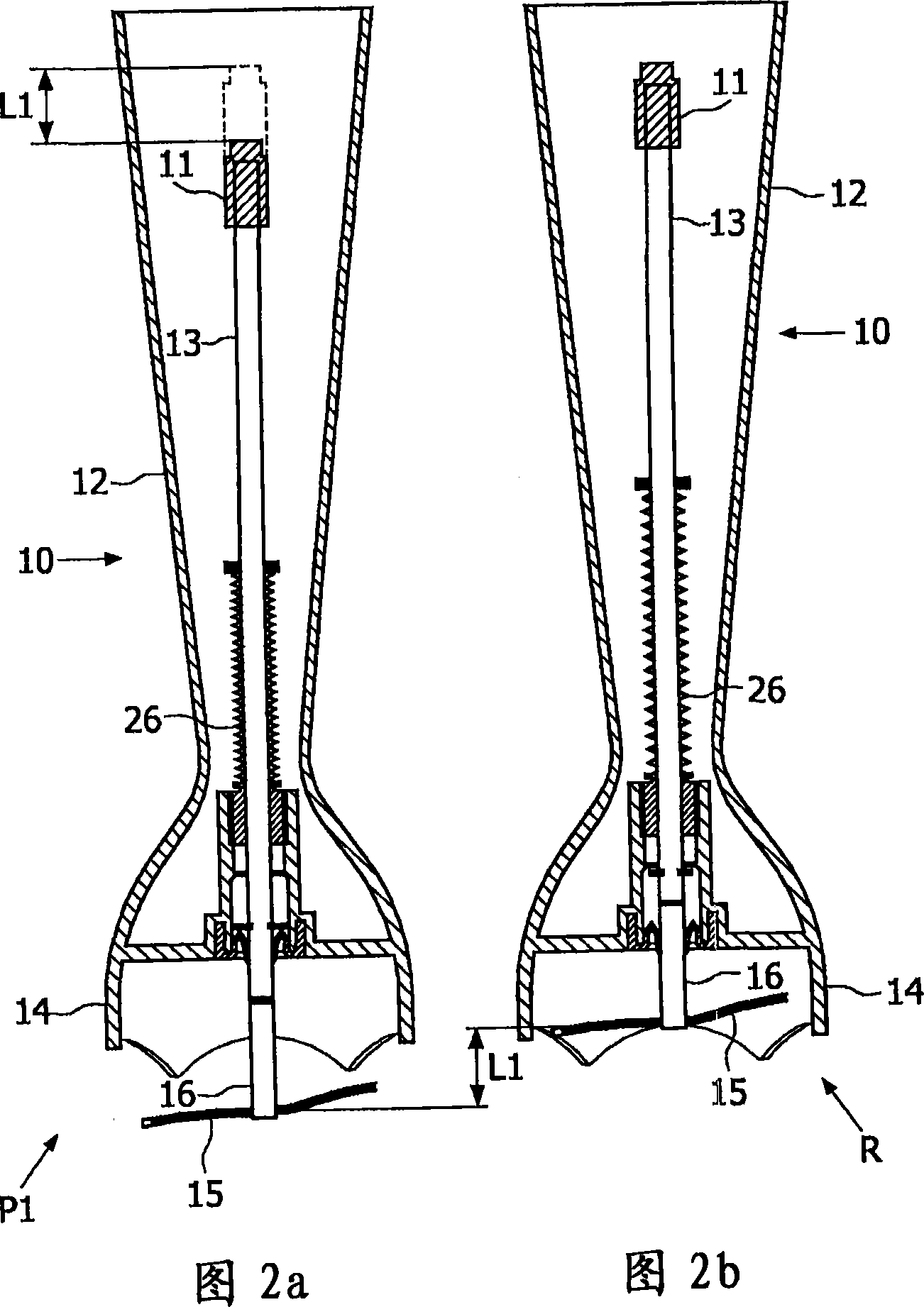

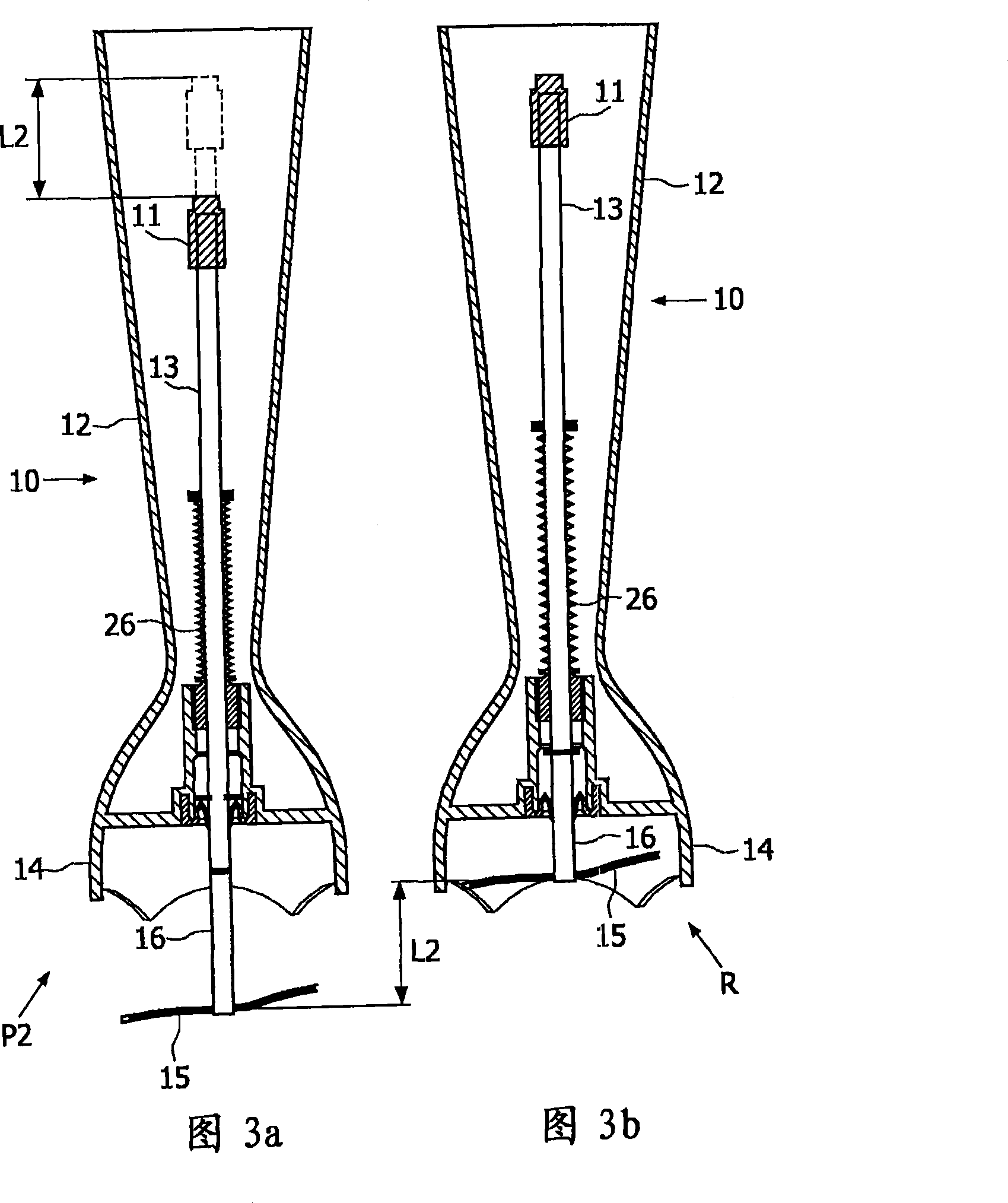

[0033] Fig. 1a, Fig. 1b, Fig. 1c show the first embodiment of the stirrer equipment 10 according to the present invention, Fig. 1a and Fig. 1b are the axial section, Fig. 1c is the bottom section. The main part is the tubular body 12 including the axis of rotation 13 . The lower end of the tubular body 12 (as shown in FIG. 1 ) is enlarged to form a cover 14 as a peripheral protection portion around the blade 15 fixed on the lower end of the rotating shaft 13 . The upper end of the rotary shaft 13 shows a connector 11 for connecting the rotary shaft 13 to a power supply unit (not shown) to cause the rotary shaft to rotate and thereby run the blade 15 . The rotating blade 15 then chops, purees, or mixes its surroundings.

[0034] Retained within the tubular body 12 is a rotating shaft 13 which can be moved axially by pushing the connector 11 with, for example, a finger, thereby bringing the blade 15 from a retracted position R ( FIG. 1 a ) inside the housing 14 to outside the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com