Circuit board fixing mechanism

A fixing mechanism and circuit board technology, applied in the direction of circuit arrangement, elastic/clamping device, etc. on the support structure, can solve the problems of inconvenience, complex installation structure, reduced efficiency, etc., to overcome the inconvenience of stacking, reduce the use of parts, save The effect of parts cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

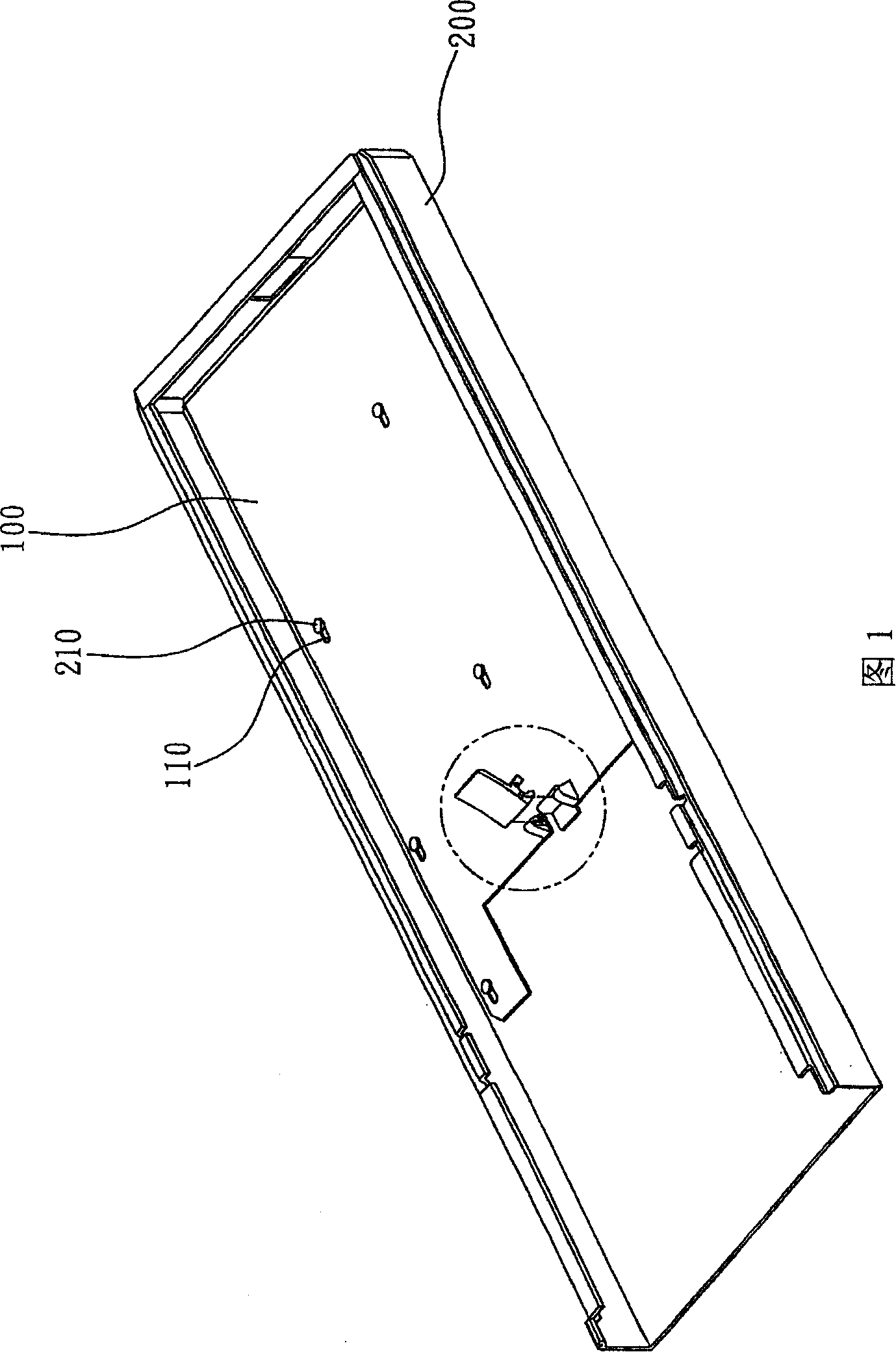

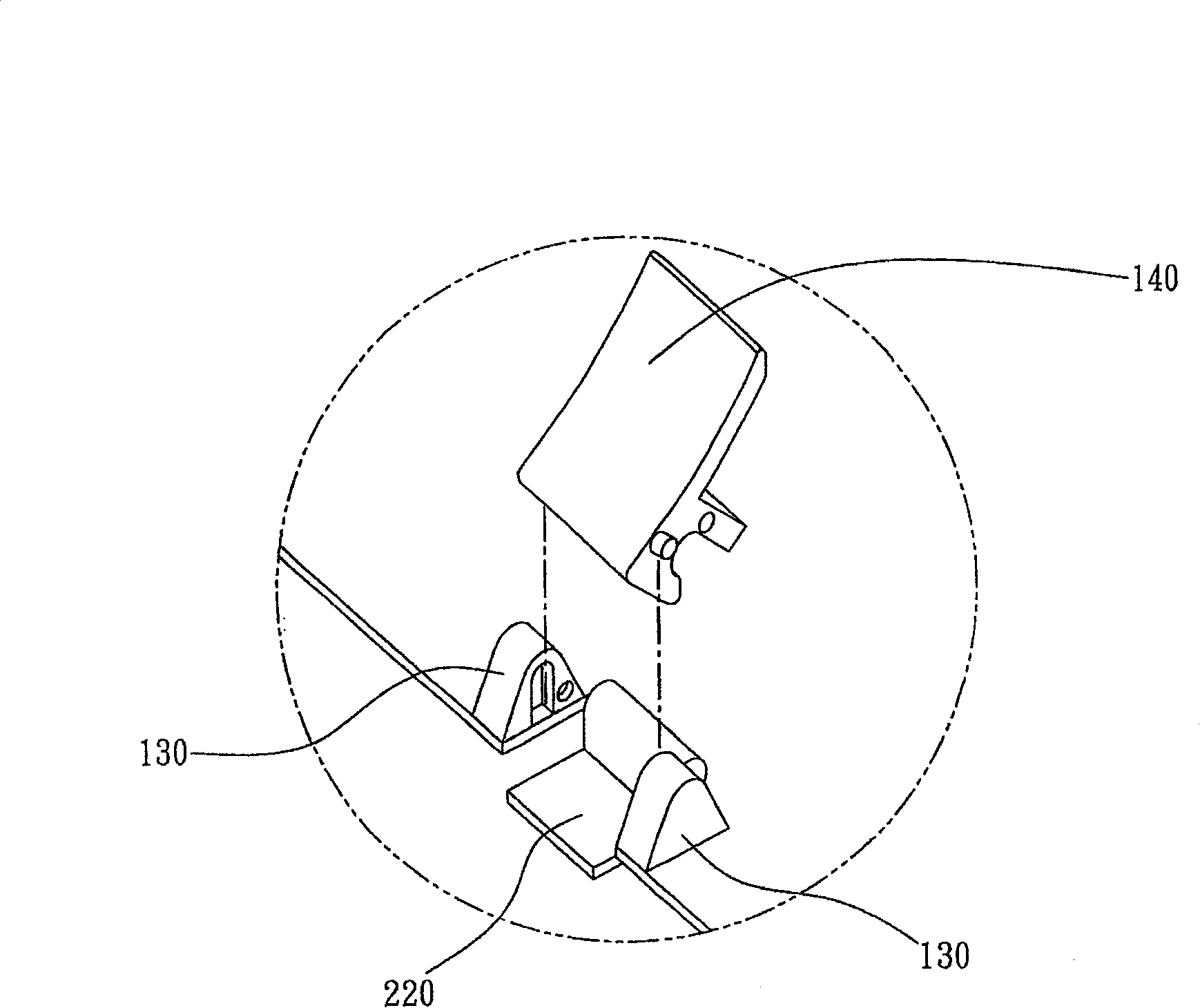

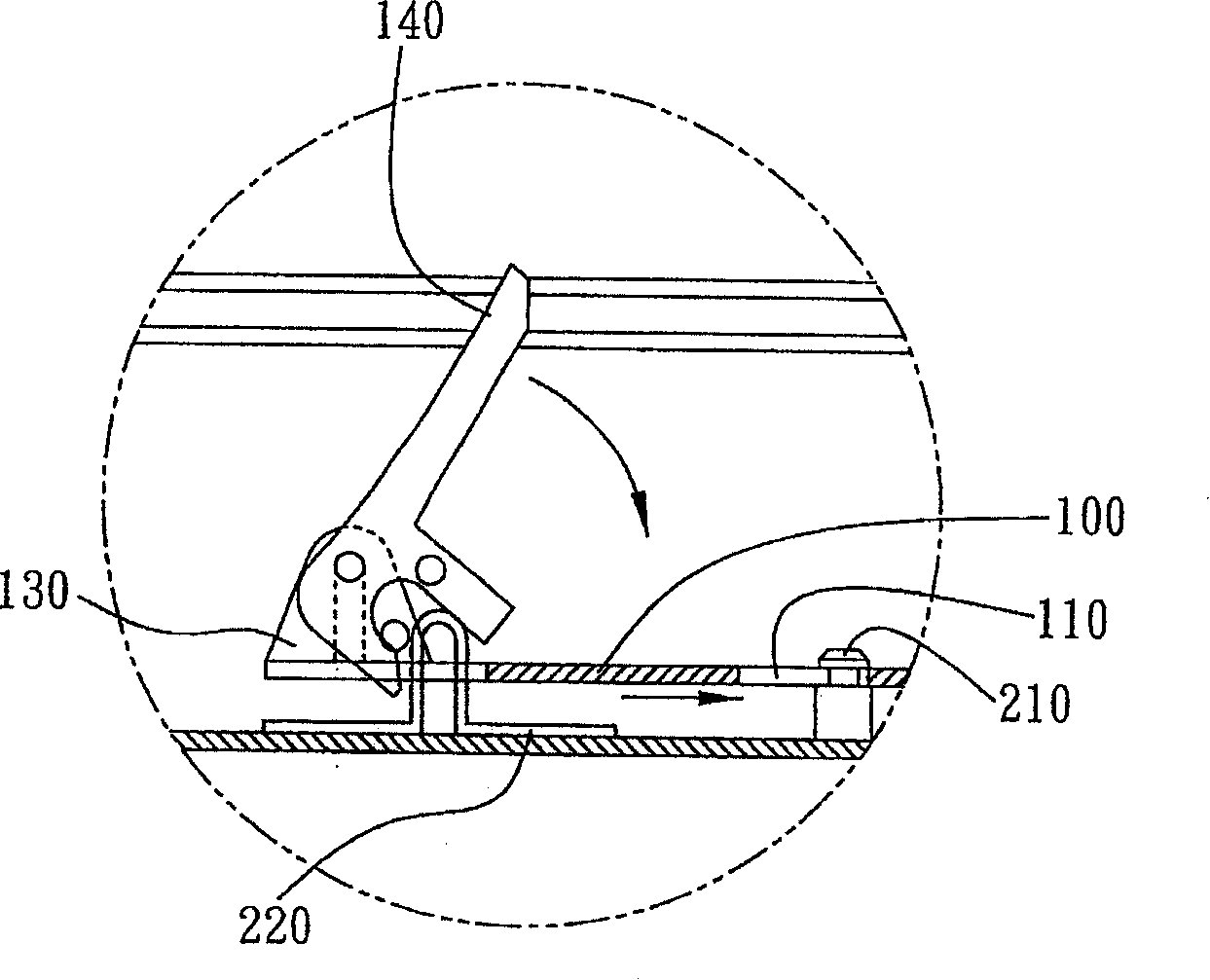

[0042] Such as image 3 The circuit board fixing mechanism shown is used to fix a circuit board 4 with a plurality of openings 41 on a setting surface 3. The circuit board 4 is an example of a mainboard used in a server, and the setting Surface 3 takes the chassis bottom plate of the server as an example. In addition, the same side of each of the openings 41 is provided with a reduced engaging section 411, that is, the opening 41 with the engaging section 411 is equivalent to a gourd as a whole. hole. The circuit board fixing mechanism of the present invention includes a first positioning portion 43 disposed on the circuit board 4 , a plurality of supports 31 disposed on the setting surface 3 , and an elastic body disposed on the setting surface 3 and having a second positioning portion 331 . The member 33, through the corresponding engagement of each support member 31 with the engaging section 411, can provide two-direction degree of freedom restriction, and at the same time...

no. 2 example

[0050] Image 6 According to the drawings drawn according to the second embodiment of the circuit board fixing mechanism of the present invention, the same elements as those of the first embodiment are represented by the same or similar element symbols, and detailed descriptions are omitted so as to make the description of this case Clearer and easier to understand.

[0051] The biggest difference between the second embodiment and the first embodiment is that the elastic member 33 of the first embodiment is an elastic arm with a bump on the top as an example, while the second embodiment is a button with a keycap .

[0052] As shown in the figure, the circuit board fixing mechanism shown in this embodiment also includes a first positioning portion 43 provided on the circuit board 4, a plurality of support members 31 provided on the installation surface 3, and a plurality of support members 31 arranged on the installation surface. 3 and the elastic member 33' with the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com