Pneumatic conveying device of tyre forming machine and method thereof

A tire building machine and pneumatic conveying technology, which is applied to pneumatic conveying devices and pushes the air film field of materials. The effect of low power and supporting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

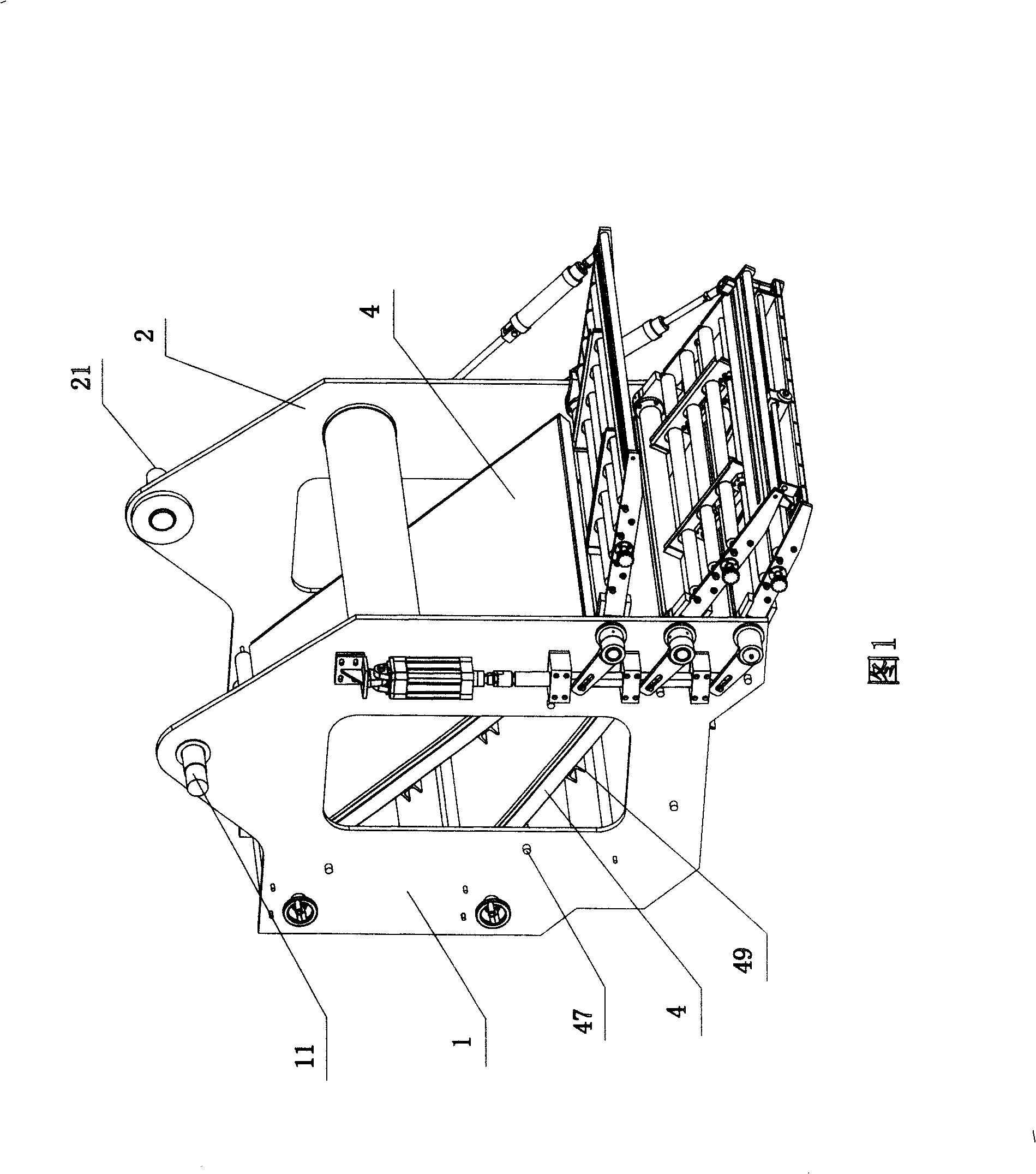

[0038] Example 1, such as Figure 1 to Figure 5 As shown, in the tire building machine using the pneumatic conveying device, the frame is respectively connected to the left wall panel 1 and the right wall panel 2 through the fixed hinge 11 and the fixed hinge 21 .

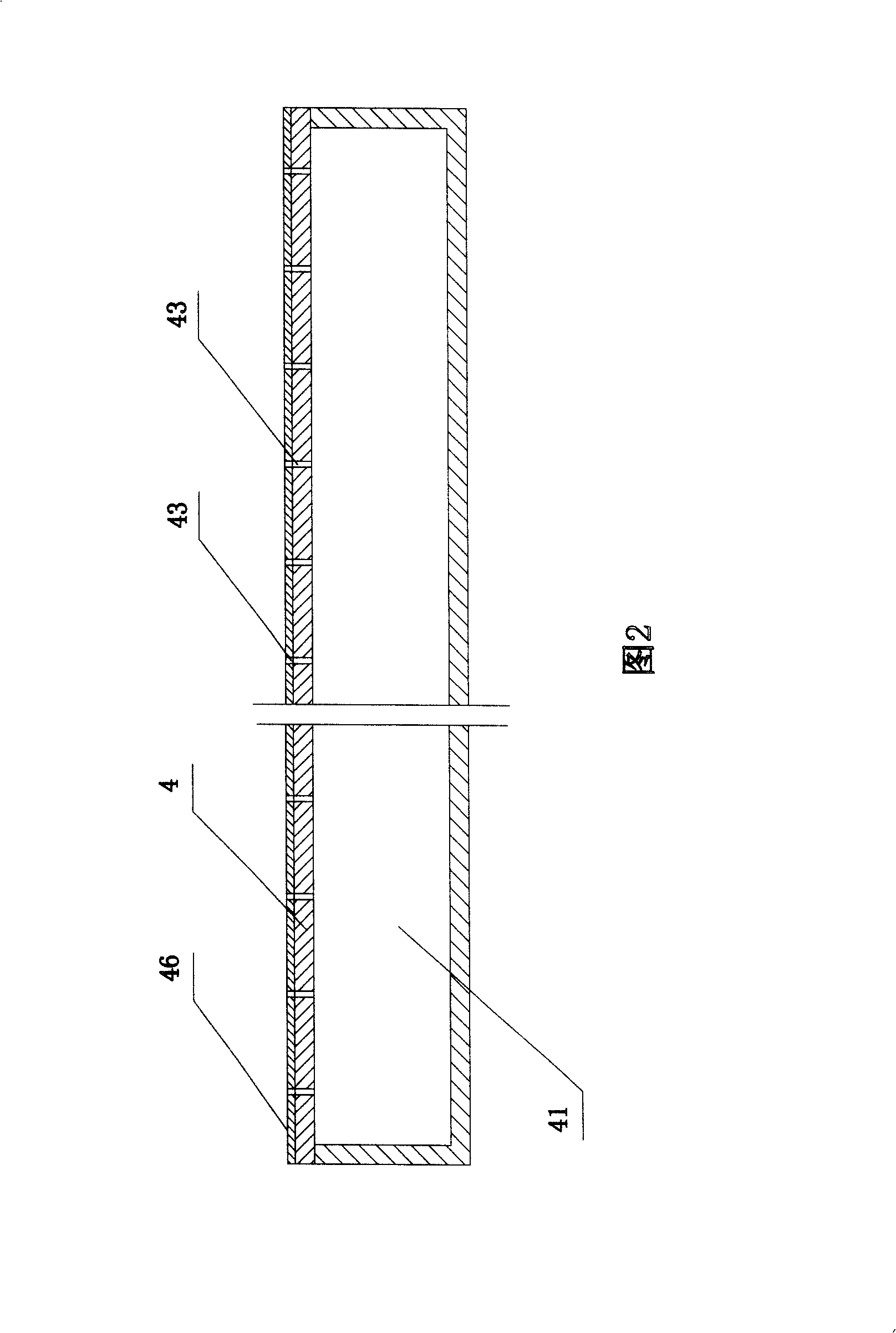

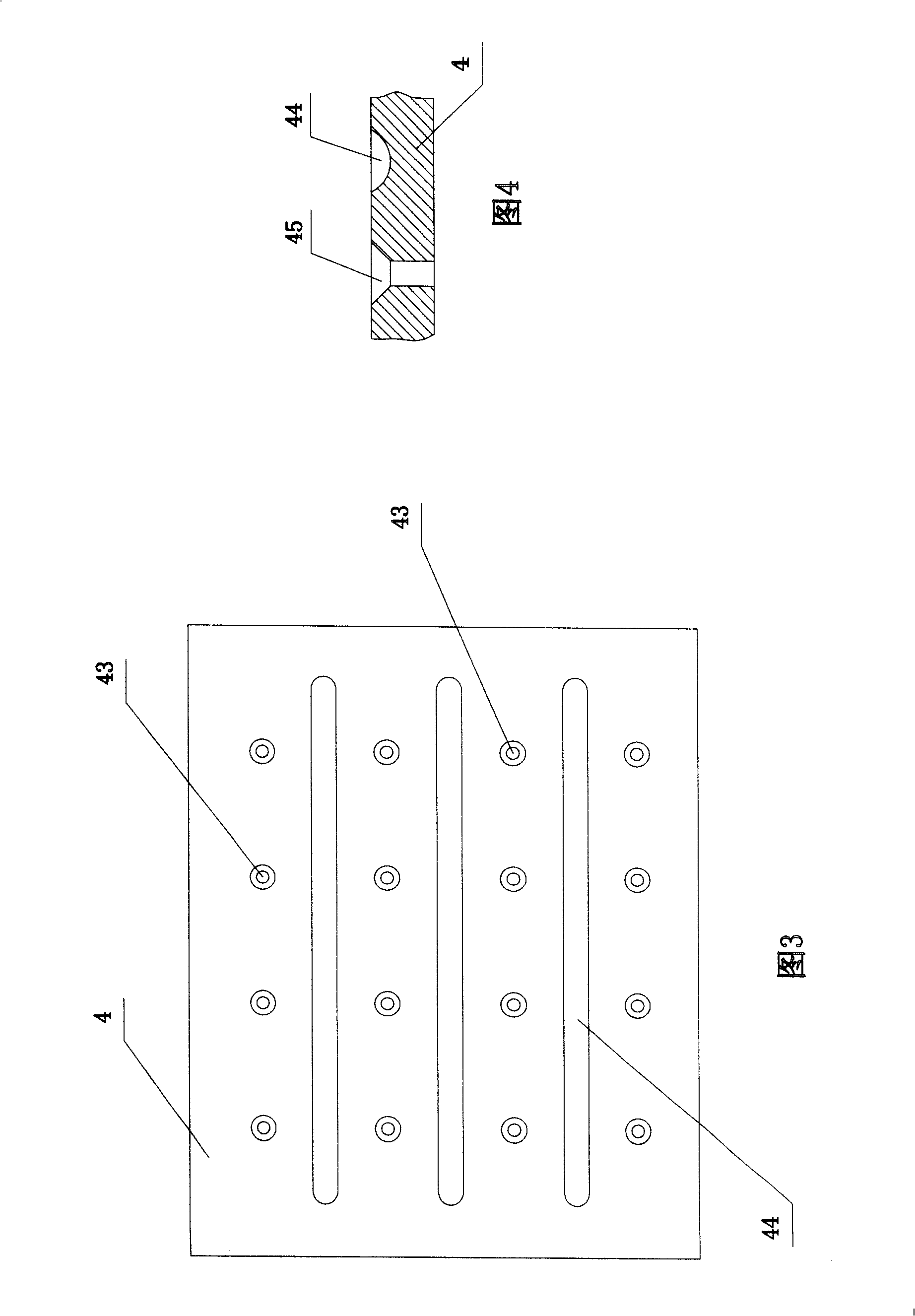

[0039] Between the left wallboard 1 and the right wallboard 2, two sets of centering devices 3 and three layers of conveying templates 4 connected in sequence are fixed. Wherein, the fixed shaft 47 fixed between the left wallboard 1 and the right wallboard 2 is installed under the conveying formwork 4, the fixing seat 48 is buckled on the fixed shaft 47, and the reinforcing rib arranged transversely is fixed below the conveying formwork 4 tendons49.

[0040] Through the above structure, when changing laminating drums of different specifications, the overall adjustment device of the frame can push and drive the left wall panel 1 and the right wall panel 2, and then drive the pneumatic conveying device as a whole to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com