Extraction device and method for use when extracting a ceramic foam filter

A removal device, ceramic foam technology, applied in the direction of improving process efficiency, screws, threaded fasteners, etc., to achieve the effect of reducing the risk of being dropped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

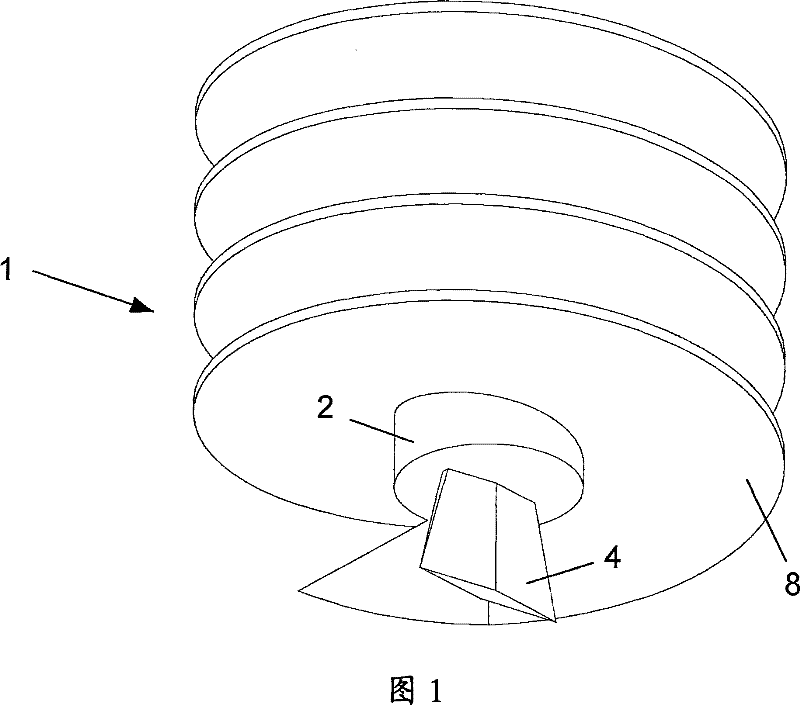

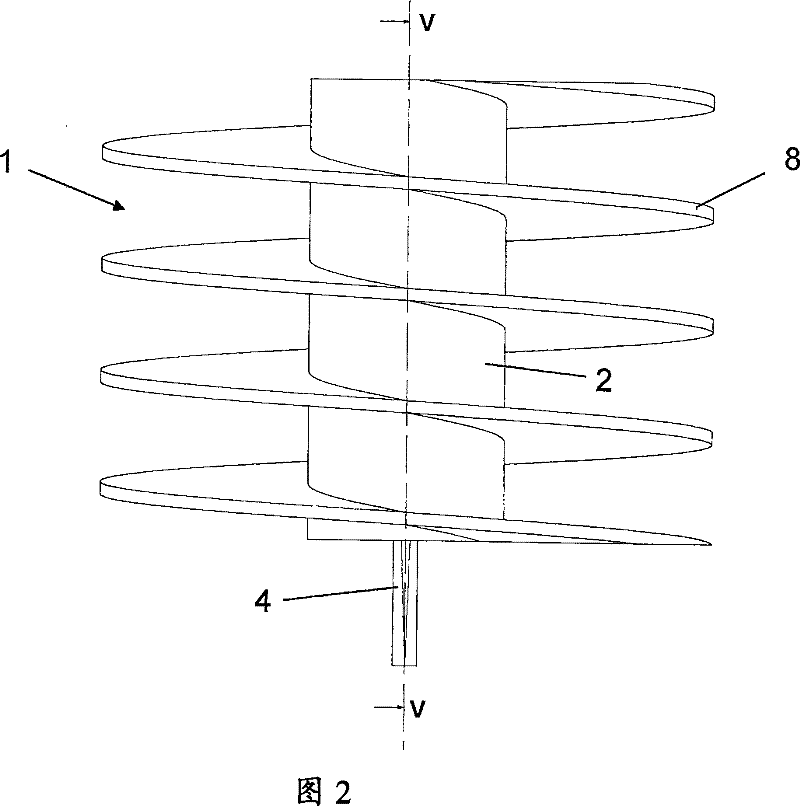

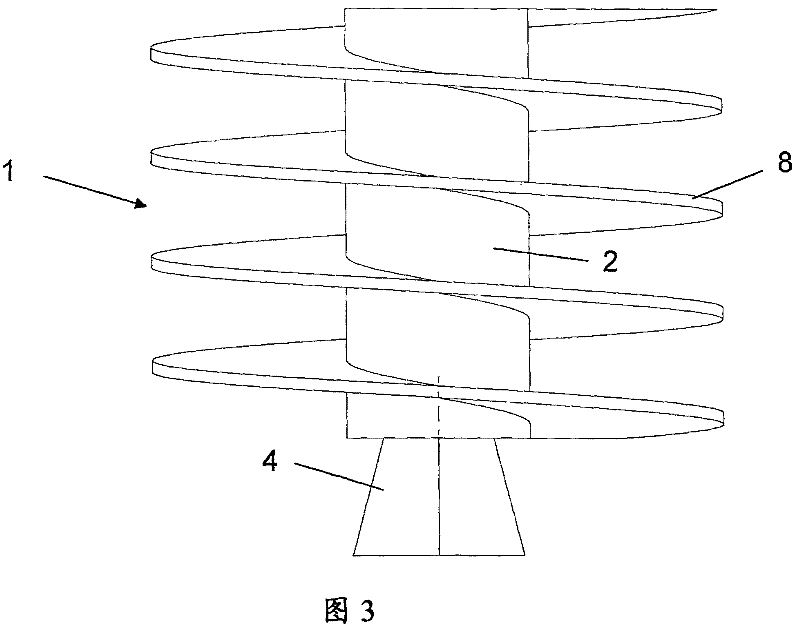

[0030] exist Figure 1 to Figure 5 The first extraction device shown in comprises an anchoring device 1 comprising a cylindrical anchoring body 2 with a cutting blade 4 at one end and a cylindrical hole 6 at the other end of the body. The profile shape of the cutting blade 4 is trapezoidal (American English: trapezoid) and the leading edge of the blade is sharpened so that it will cut into the ceramic foam filter. The hole 6 has an internal thread (not shown) forming connection means for connecting the extraction device to an insertion / extraction tool (not shown). The insertion / extraction tool may for example consist of a T-shaped bar with a thread at one end for engagement with an internal thread in the hole 6 . The insertion / extraction tool may also include lifting lugs for attachment to a crane or other lifting device.

[0031] An external helical thread 8 extends outwardly from the cylindrical surface of the anchor body 2 . In the embodiment shown in the figures, the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com