Dish washer

A dishwasher, advanced technology, applied in the direction of washing/rinsing machines for tableware, washing/rinsing machine parts for tableware, cleaning equipment, etc., can solve problems such as impossible to prevent leakage, complex sealing measures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

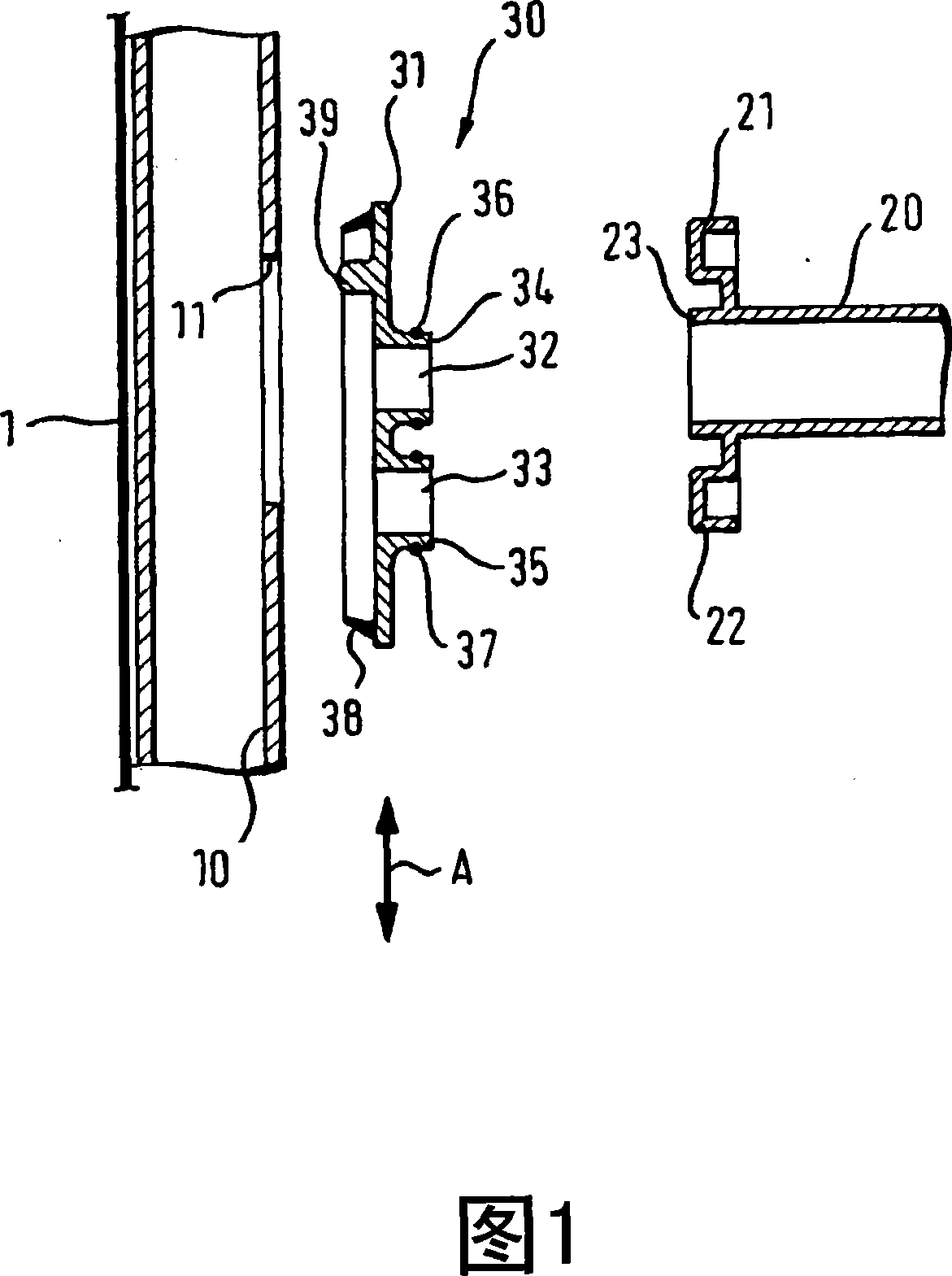

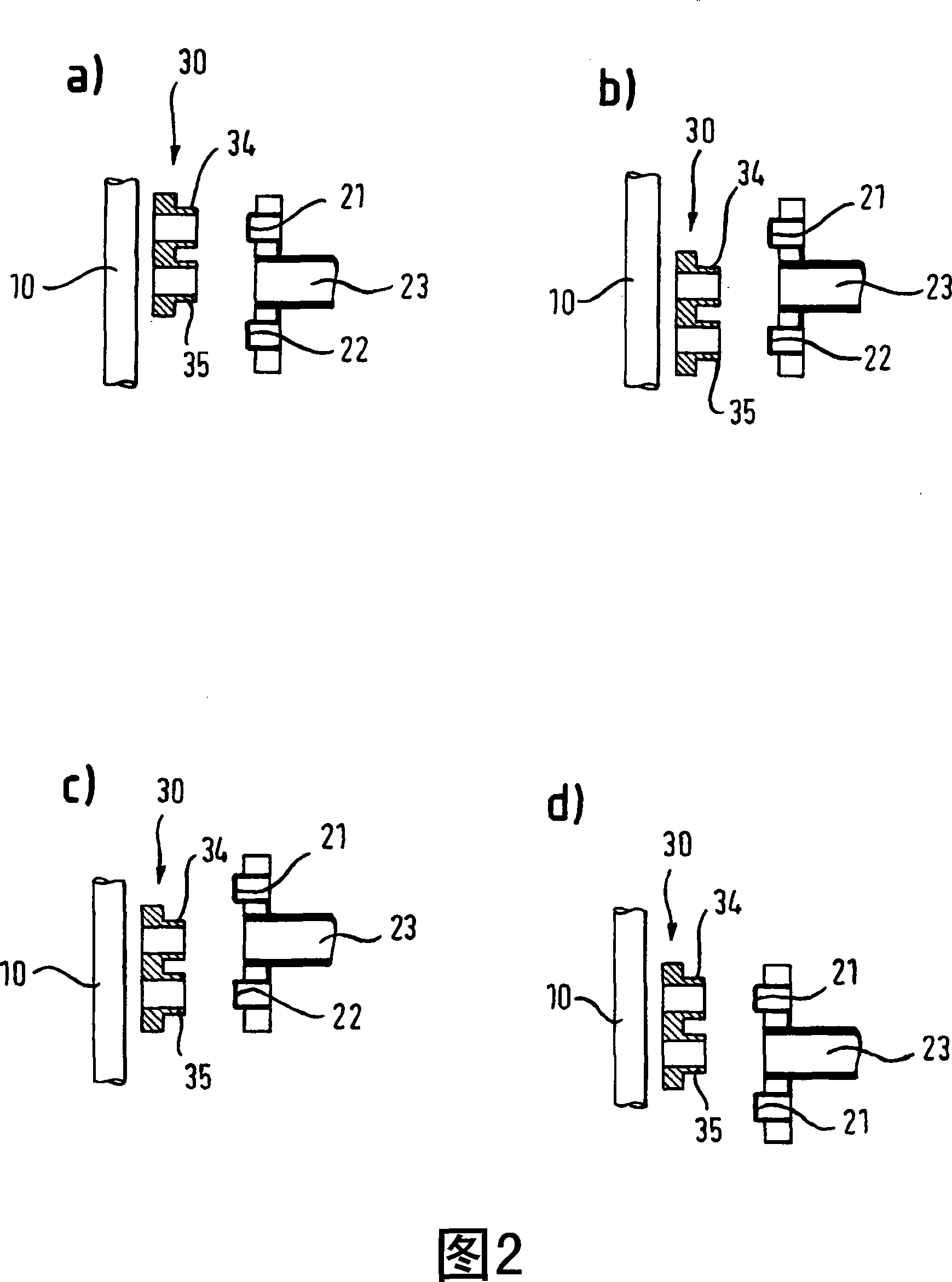

[0016] The dishwasher of the invention (not shown in more detail) comprises a height-adjustable crockery basket (not shown) to which is fastened a designated spray arm (not shown) and its water inlet pipe 20 . The spray arm is mounted in a known manner on a horizontally arranged water inlet pipe 20 via bearings (not shown in more detail). In an exemplary embodiment of the present invention, the water inlet pipe 20 is connected to the supply line 10 fastened to the side wall 1 of the washing chamber via a coupling 30 . Alternatively, a connection to the rear wall of the washing chamber is also possible for this purpose. The supply line 10 comprises an opening 11 facing the water inlet pipe 20 .

[0017] The coupling 30 comprises a coupling disc 31 which is mounted movably in the vertical direction (arrow A) on the channel of the supply line 10 (not shown). Two outlet connections 34 , 35 protruding in the direction of the water inlet pipe 20 are formed on the coupling disc 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com