Treating agent for synthetic fiber and treating method for the same

A technology of synthetic fiber and treatment method, which is applied in the field of treatment agent for synthetic fiber, and can solve problems such as insufficiency and reduction in silk strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 {Preparation of Treatment Agent (P-1)}

[0037] 10 parts of the following isocyanuric acid derivative (K-1), 20 parts of the following lubricant (L-1), 10 parts of the following lubricant (L-2), and the following emulsifier (E-1) 50 parts, 10 parts of the following emulsifier (E-2), and 1 part of the following antistatic agent (S-3) were uniformly mixed to prepare the treatment agent (P-1) of Example 1.

[0038] Isocyanuric Acid Derivatives (K-1): Tris(2-Hydroxyethyl)isocyanurate Tripropionate

[0039] Lubricant (L-1): Dioleyl Thiodipropionate

[0040] Lubricant (L-2): Bisphenol A dilaurate

[0041] Emulsifier (E-1): A polyoxyalkylene aliphatic polyester compound obtained by adding 20 mol of ethylene oxide (hereinafter abbreviated as EO) to 1 mol of hydrogenated castor oil.

[0042] Emulsifier (E-2): an ester compound of 1 mol of polyoxyalkylene castor oil and 3 mol of capric acid obtained by adding 40 mol of EO to 1 mol of castor oil.

[0043] Antistatic ...

Embodiment 2~68 and comparative example 1~17

[0044] Examples 2 to 68 and Comparative Examples 1 to 17 {Preparation of Treatment Agents (P-2) to (P-68) and Treatment Agents (R-1) to (R-17)}

[0045] Processing agent (P-2)-(P-68) and processing agent (R-1)-(R-17) were prepared similarly to processing agent (P-1). The contents of the components used in the preparation of the treatment agents of the above examples are shown in Tables 1 to 5, and the contents of the treatment agents prepared in the above examples are shown in Tables 6 to 14.

[0046] [Table 1]

[0047]

[0048] [Table 2]

[0049]

[0050] [table 3]

[0051]

[0052] In Table 3, the number average molecular weights of the compounds are values measured with HLC-8120GPC manufactured by Tosoh Corporation.

[0053] [Table 4]

[0054]

[0055] [table 5]

[0056]

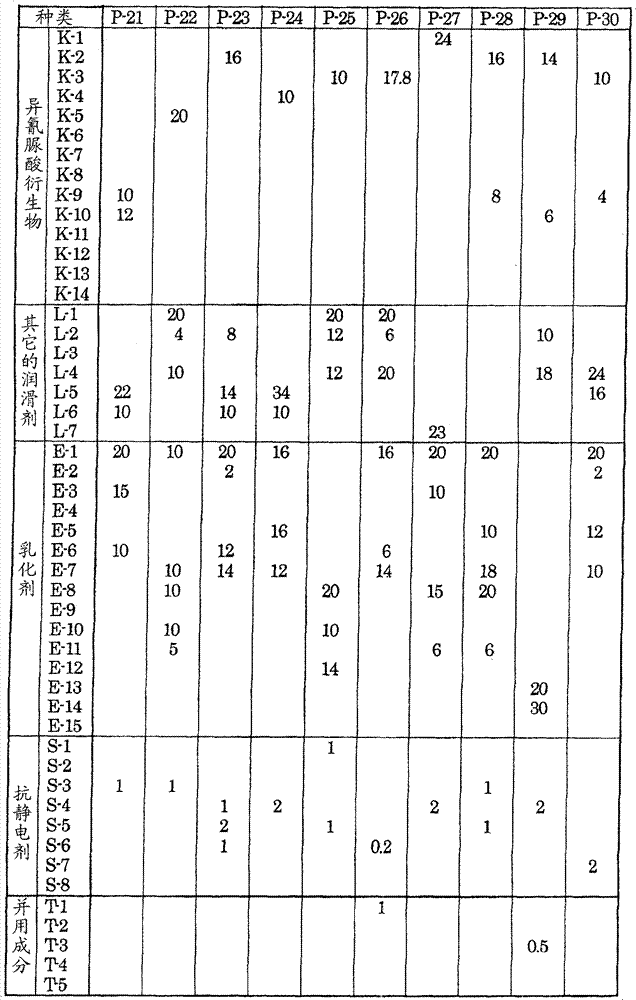

[0057] [Table 6]

[0058]

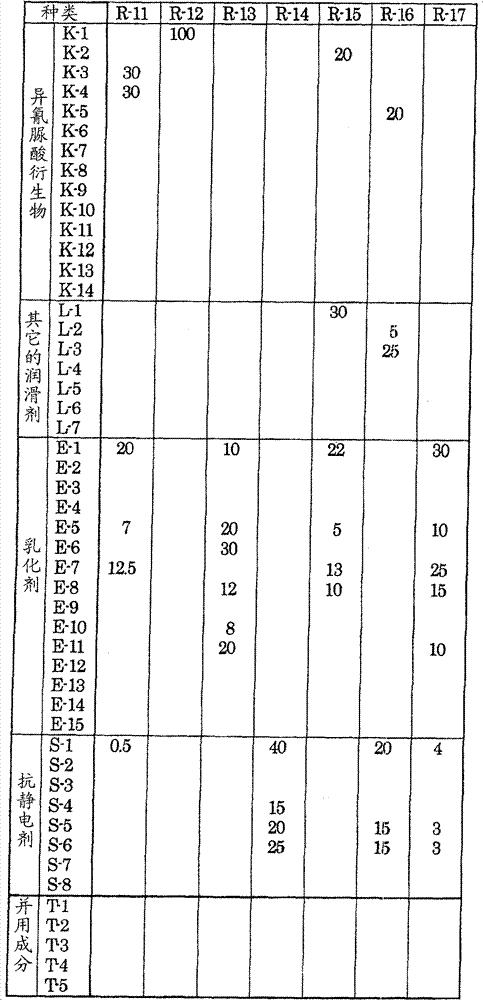

[0059] [Table 7]

[0060]

[0061] [Table 8]

[0062]

[0063] [Table 9]

[0064]

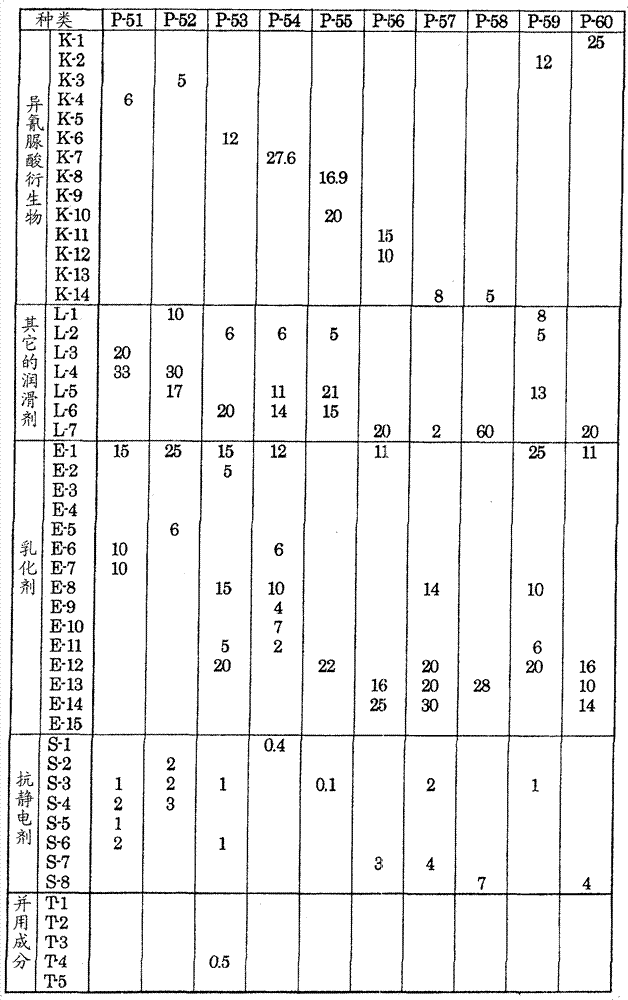

[0065] [Table 10]

[0066]

[0067] [Table 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com