Low-speed fuel channel for gasifier

A technology of fuel channels and vaporizers, which is applied in the direction of carburetors, charging systems, idle devices, etc., can solve the problems of short channel lengths, inability to completely eliminate fuel retention, etc., and achieve prevention of changes, good atomization, and simple formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

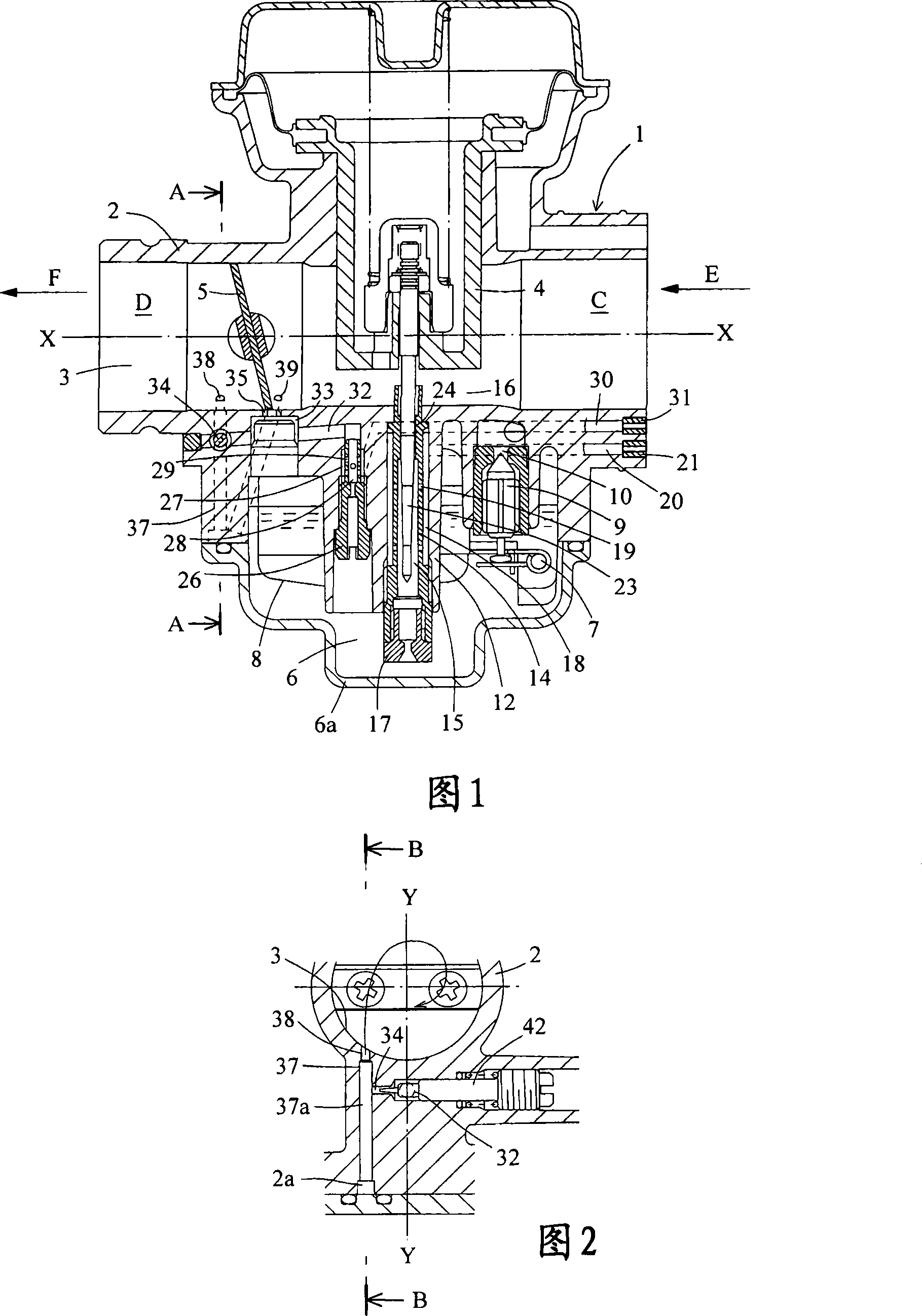

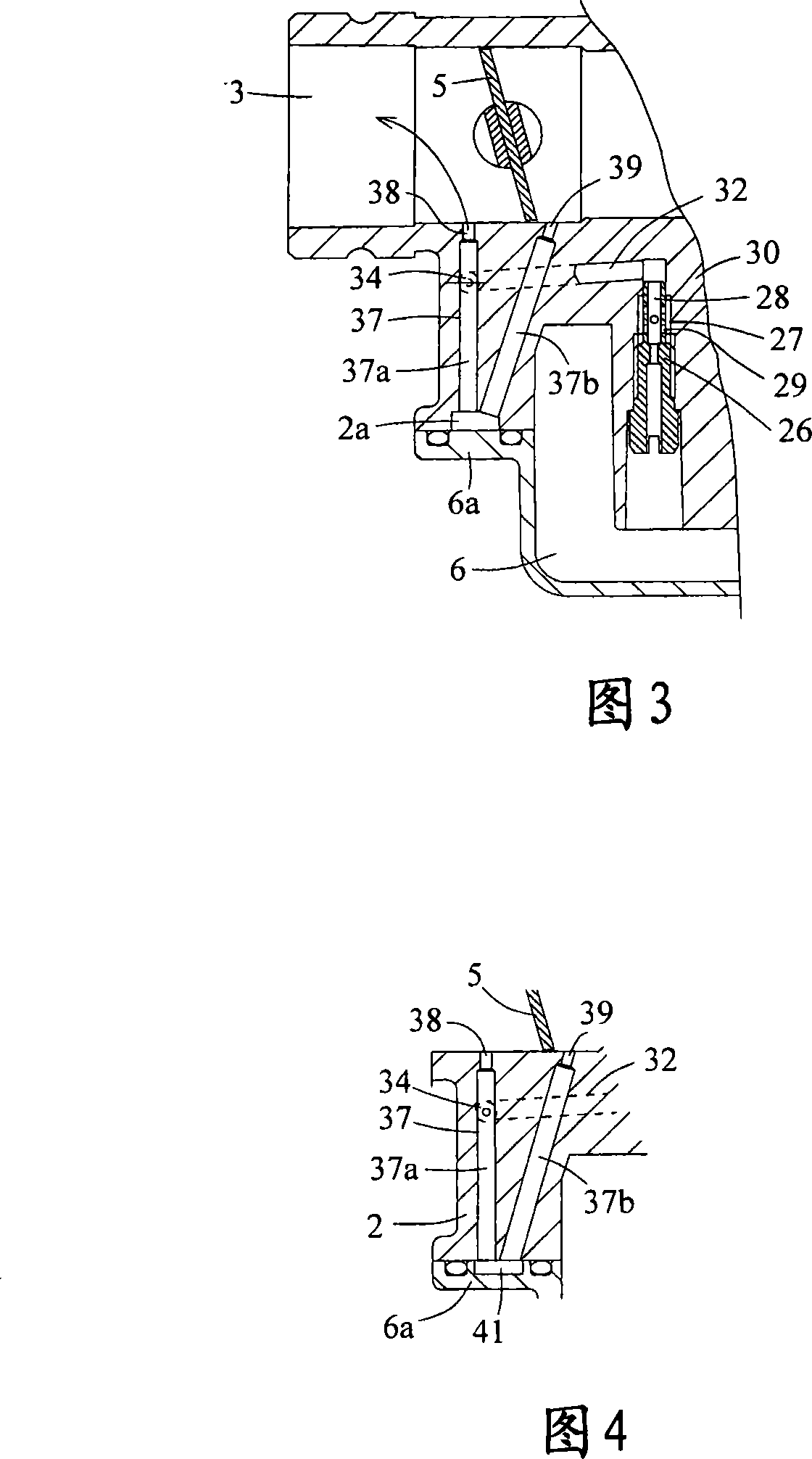

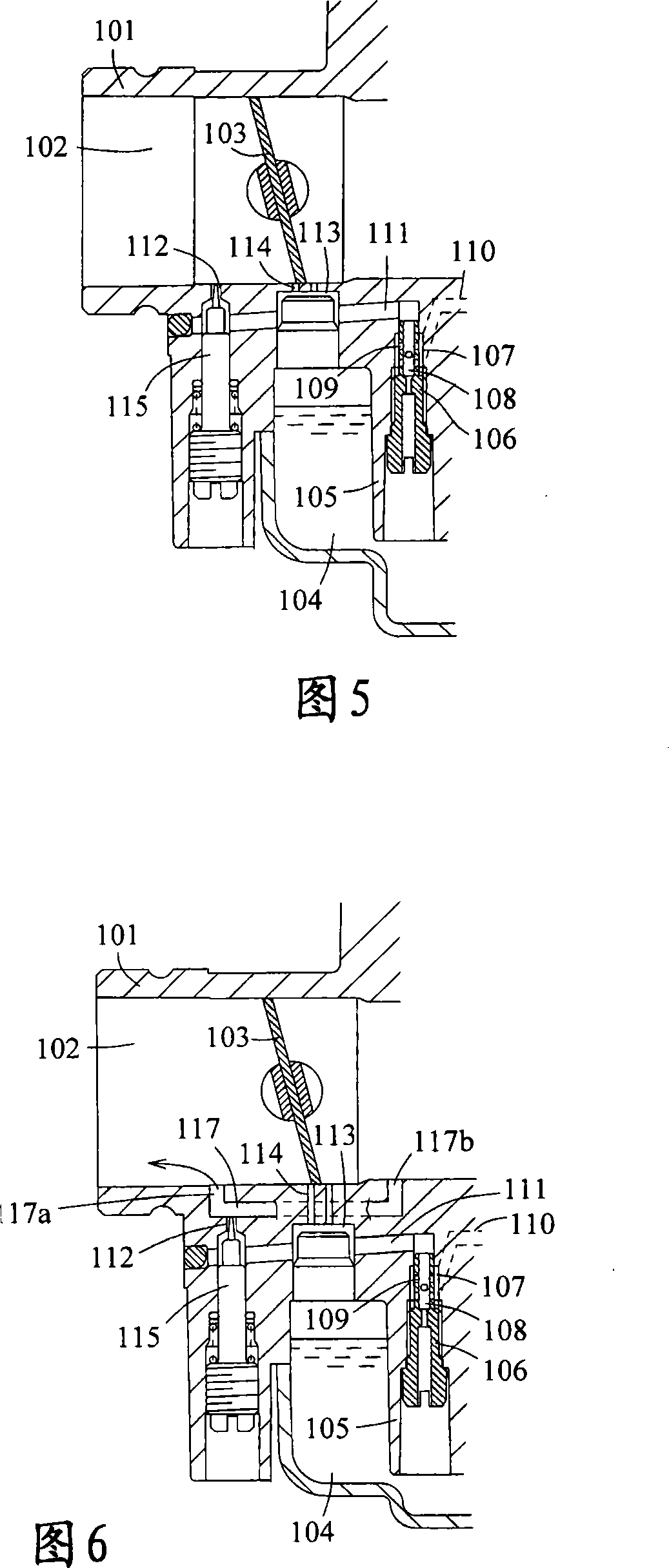

[0030] Fig. 1 is a cross-sectional view of Embodiment 1 of the gasifier according to the present invention, Fig. 2 is a cross-sectional view along line A-A of Fig. 1 , and Fig. 3 is a cross-sectional view along line B-B of Fig. 2 .

[0031] In Fig. 1 to Fig. 3, 1 is a gasifier, and its main body 2 is penetrated out of an air intake passage 3, as shown by the arrow E in Fig. 1, the upstream side C of the air intake passage for sucking in air is connected to the On the air cleaner not shown, as indicated by the arrow F, the downstream side D where the mixed gas flows out is connected to the intake port of the engine via the intake manifold not shown in the figure. In addition, an intake piston 4 is disposed in the intake passage 3 so as to be movable up and down, and a butterfly throttle valve 5 is disposed on the downstream side of the intake piston 4 .

[0032] In FIG. 1 , below the aforementioned air intake passage 3 , a float chamber 6 is provided with a float chamber main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com