Lens module assembling test device and assembling test method

A lens module, assembly and testing technology, applied in the direction of measuring device, installation, force/torque/power measuring instrument, etc., can solve problems such as difficult to achieve industrial production, errors, time-consuming lens module assembly process, etc., to achieve the best imaging quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

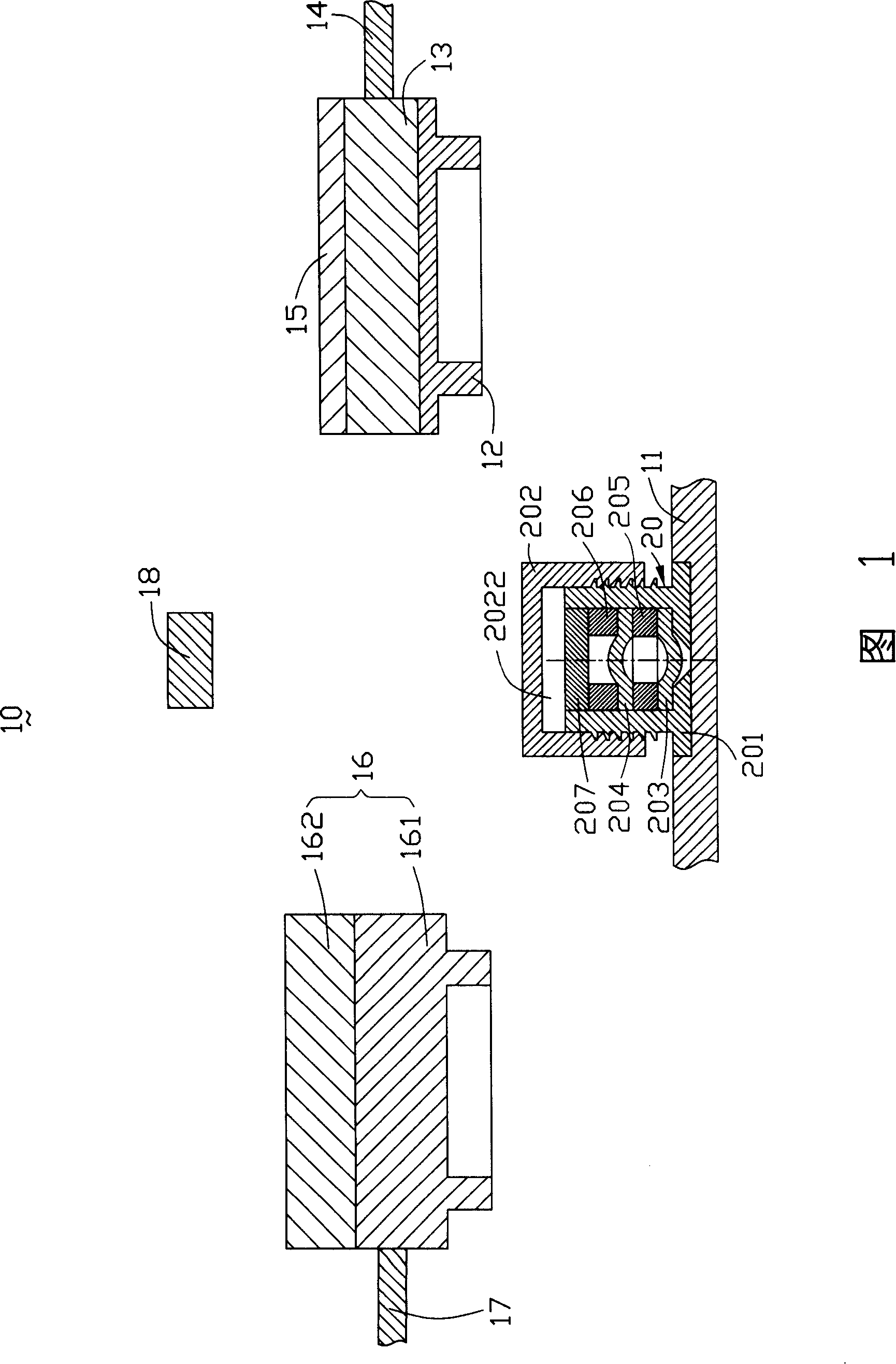

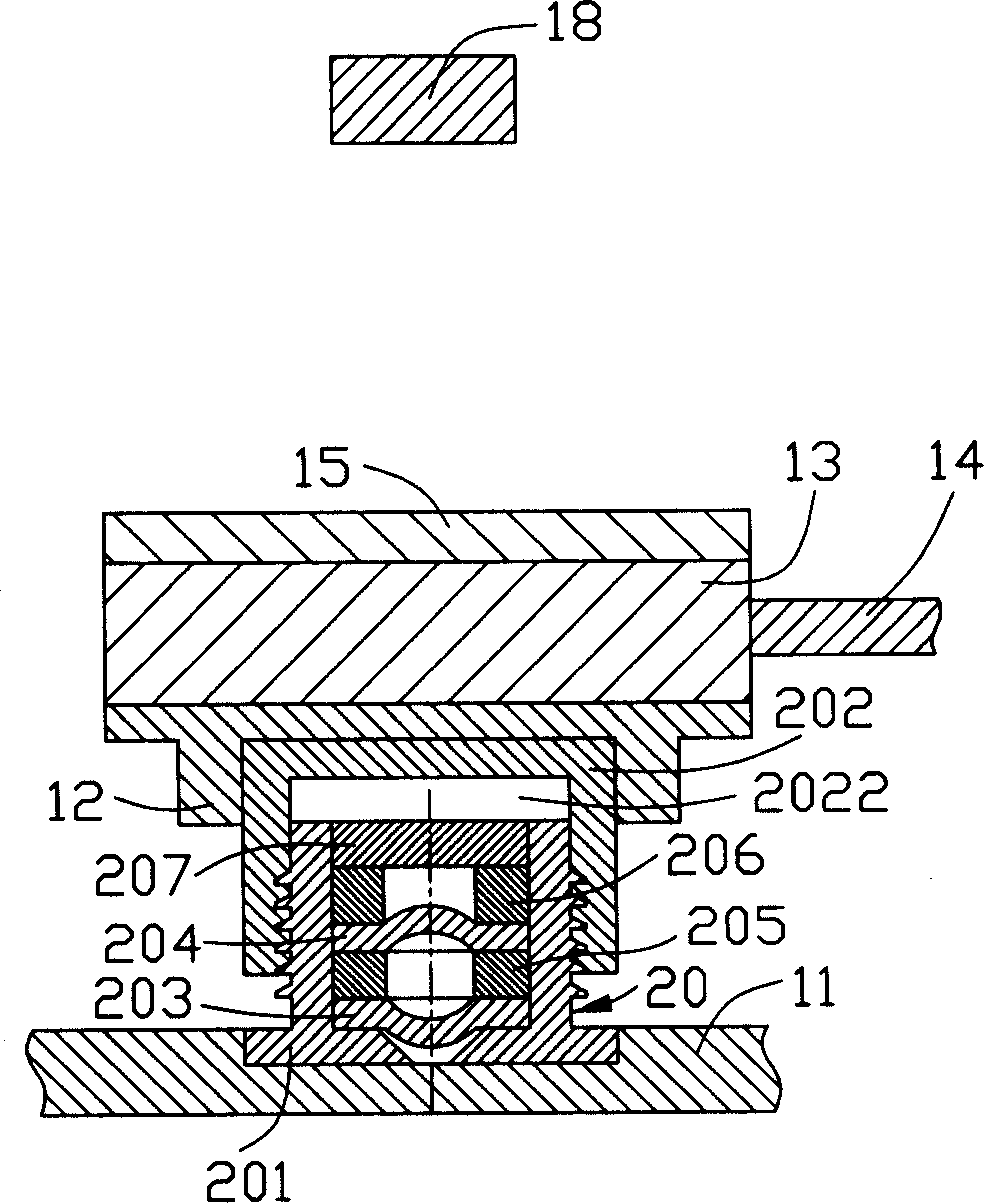

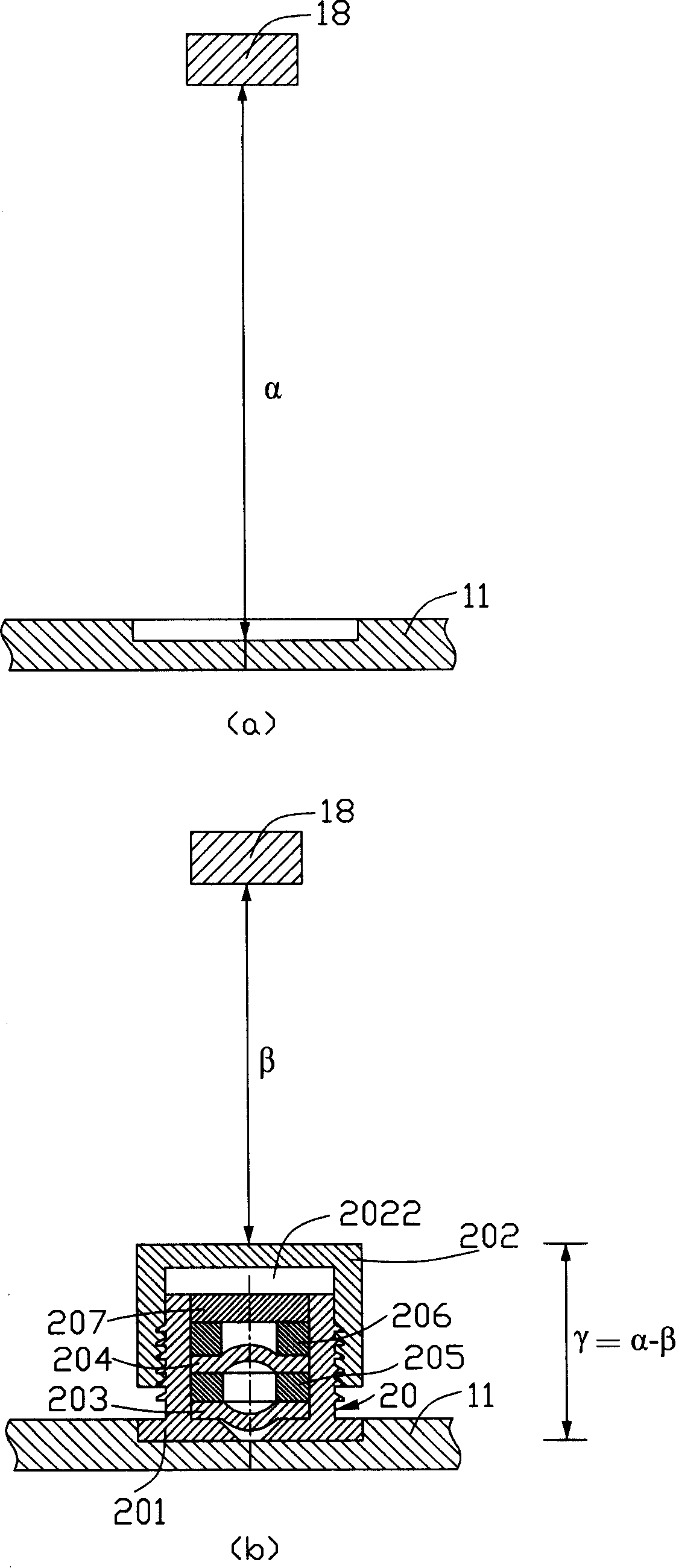

[0016] Please refer to FIG. 1 , the lens module assembly testing device 10 provided by the embodiment of the present invention is used to make the lens holder 202 and the lens barrel 201 containing the optical elements screw together to assemble the lens module 20, and test the Torque between the lens barrel 201 and the lens base 202 of the lens module 20 . The optical elements accommodated by the lens barrel 201 can include lenses 203 and 204, a filter 207, and spacers 205 and 206 for spacing the lenses 203, 204 and the filter 207. The outer surface of the lens barrel 201 is provided with An external thread (not marked), the mirror base 202 defines a receiving hole 2022 , and an inner thread (not marked) is provided on the inner wall of the receiving hole 2022 . The lens module assembly test device 10 includes an assembly device (not marked) and a torque te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com