Rolling guide device and method of manufacturing the same

A technology of rolling guidance and manufacturing method, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of increased processing time and the number of parts, long processing time, and troublesome assembly of sliding parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

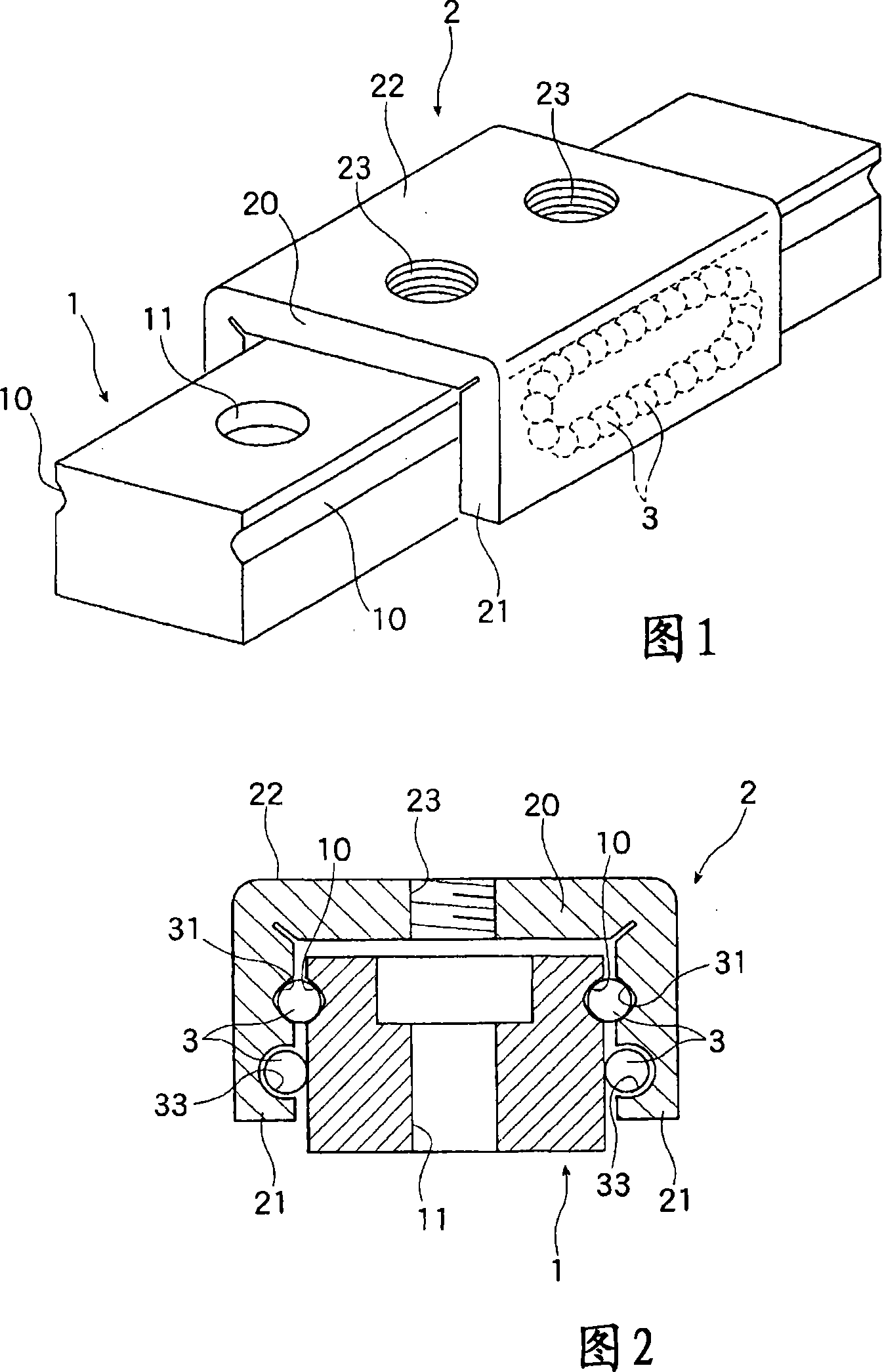

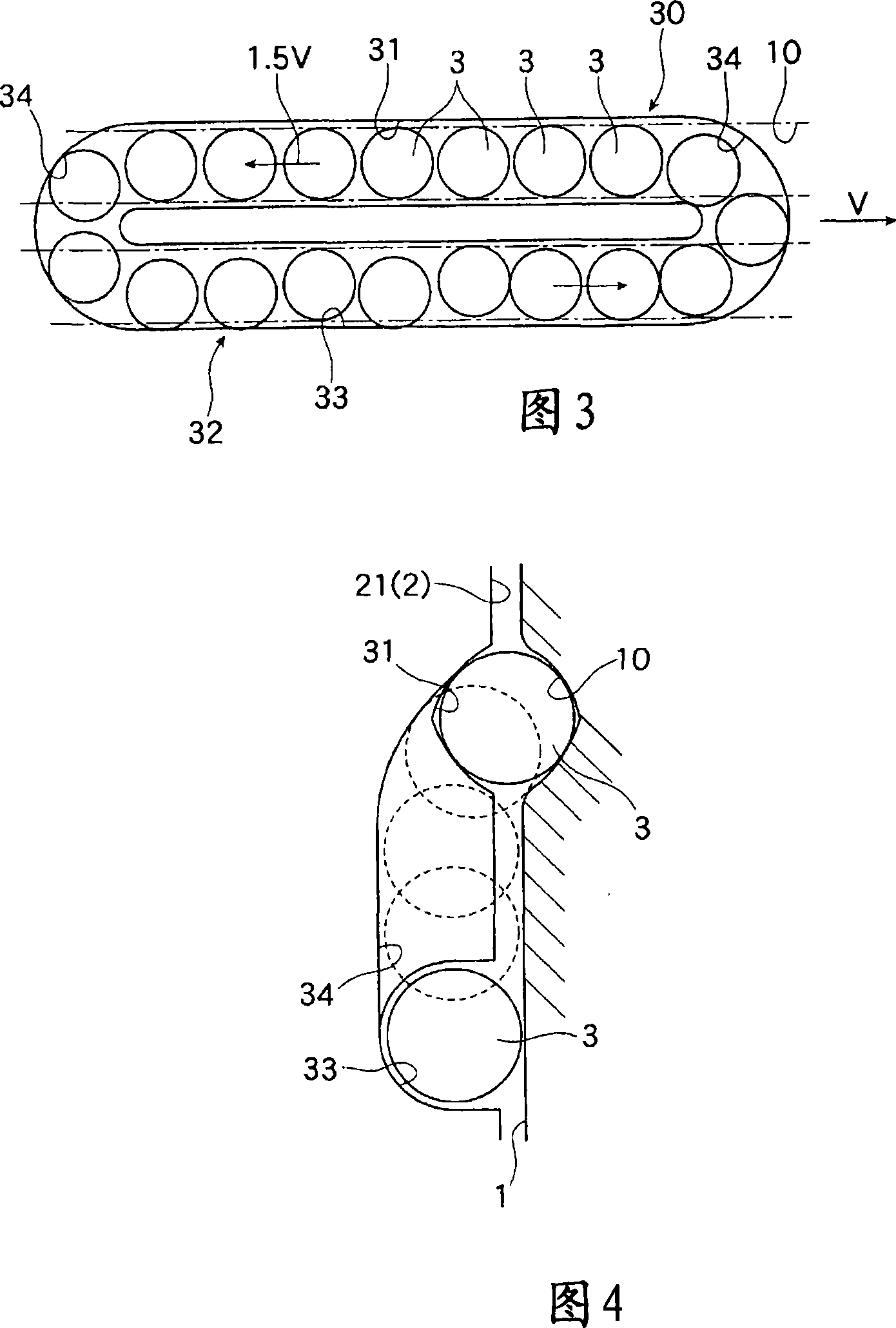

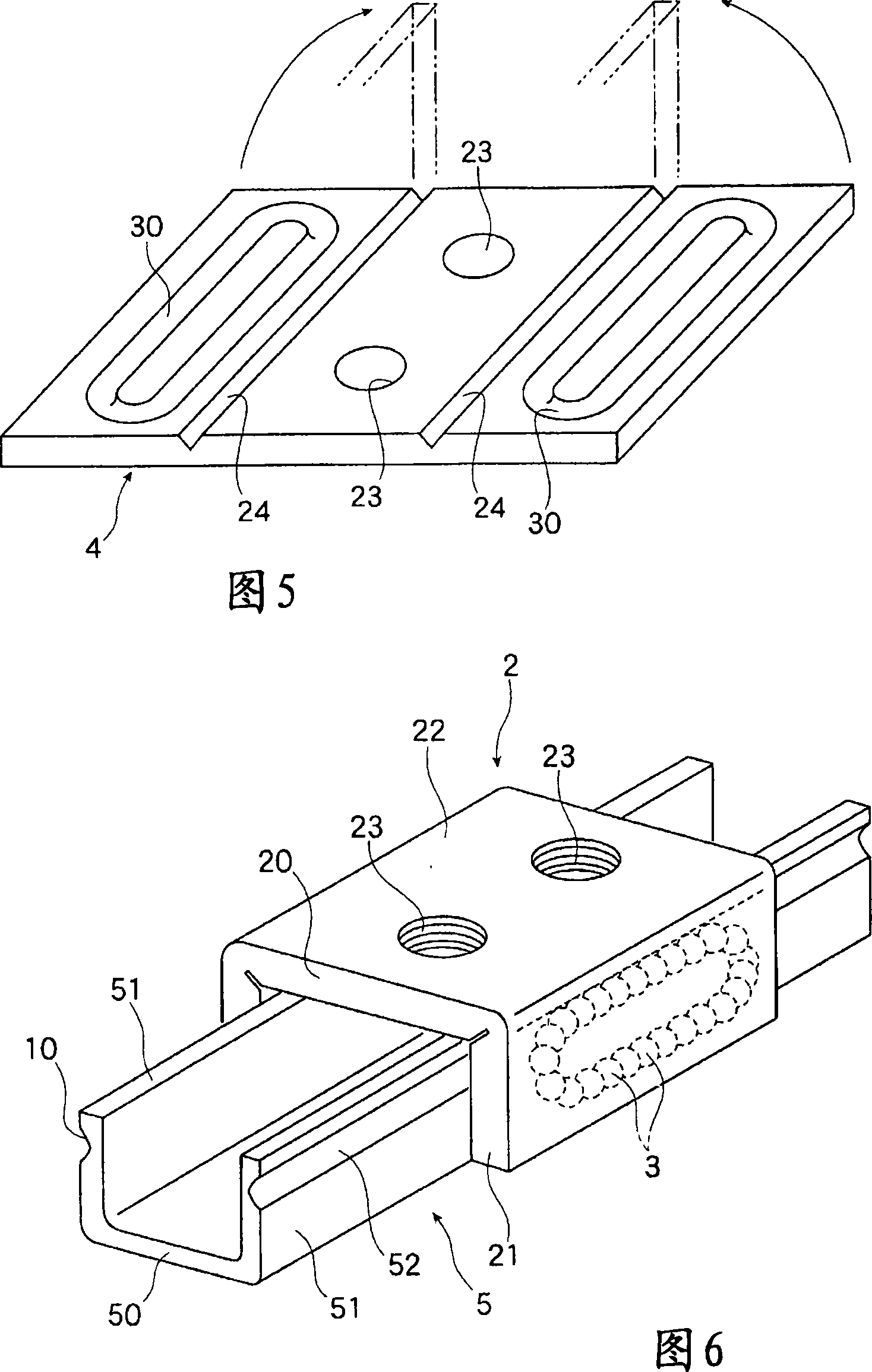

[0026] Next, the rolling guide device of the present invention will be described in detail with reference to the drawings.

[0027] 1 and 2 show a first embodiment of a rolling guide device to which the present invention is applied. The rolling guide device according to the first embodiment is composed of a long track rail 1 having a substantially rectangular cross section, and a slide member 2 formed in a tunnel shape and assembled to the track rail 1 via a plurality of balls 3 . The above-mentioned sliding member 2 can freely reciprocate on the track guide rail 1 while straddling the track guide rail 1 .

[0028] On both side surfaces of the track guide rail 1, one rolling groove 10 for each ball 3 is formed in the longitudinal direction. In the rolling groove 10, two rolling surfaces on which the ball 3 rolls intersect at 90 degrees, and the cross section thereof is formed in a so-called Gothic arch shape. Therefore, the ball 3 is in two-point contact with the rolling gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com