Screen stencil sheet capable of self-cleaning screen stencil

A self-cleaning and screen technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of shortening the life of the rod and blocking the screening, and achieve the effect of improving the service life, increasing the friction surface and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

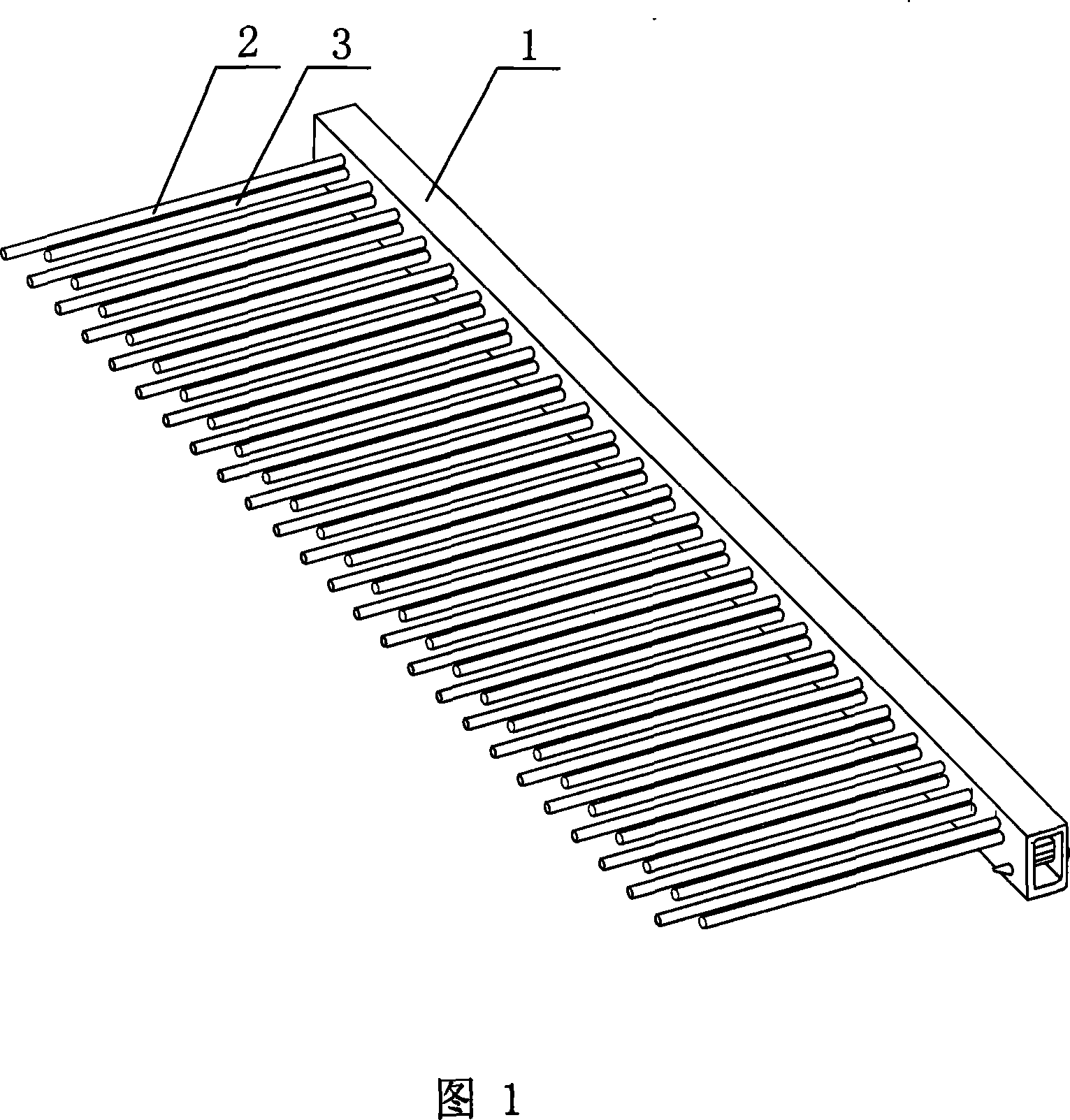

[0014] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0015] As shown in Fig. 1, the present invention comprises screen bar and beam frame 1 made of elastic metal, and every two of said screen bars are set up vertically up and down, and one end of the screen bar is perpendicular to beam frame 1 and is fixed on beam frame 1, the other end is in a free state, and each group of sieve bars is arranged on the beam frame 1 in parallel according to the set interval.

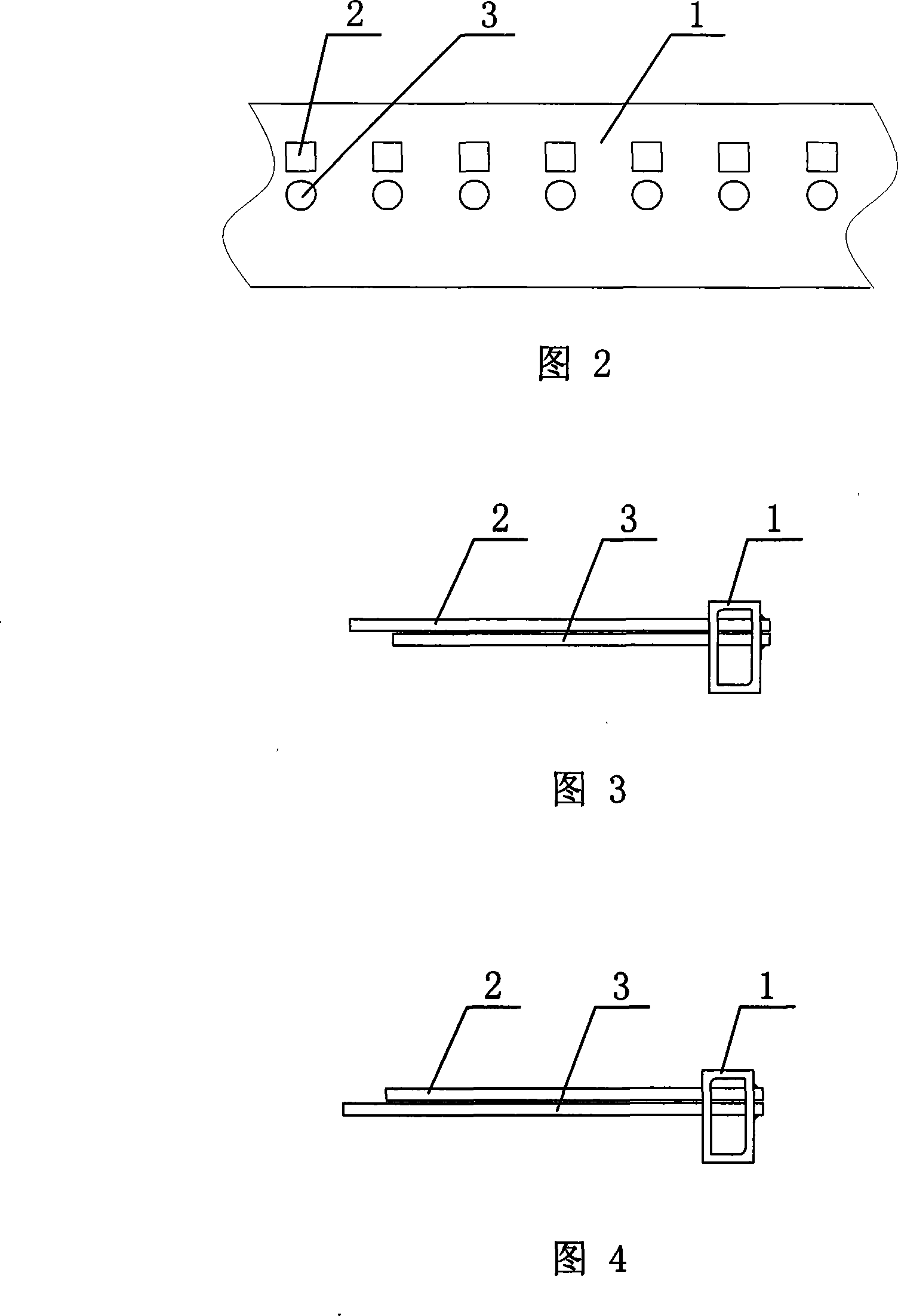

[0016] As shown in Figure 2, there is a certain gap between the two vertical screen bars of the present invention, and they can also be close together up and down. Among the two vertical sieve bars, the cross section of the upper sieve bar 2 is polygonal, and the cross section of the lower sieve bar 3 is circular. The upper sieve bar 2 is elastic squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com