Automatically rubber mixing technique for mill mixer

An open mill and rubber mixing technology, which is applied in the field of automatic rubber mixing technology of the open mill, can solve problems such as danger, poor control of the process, and difficulty in stabilizing the quality of rubber processing, so as to improve consistency, avoid manual labor intensity and Operational Hazardous Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

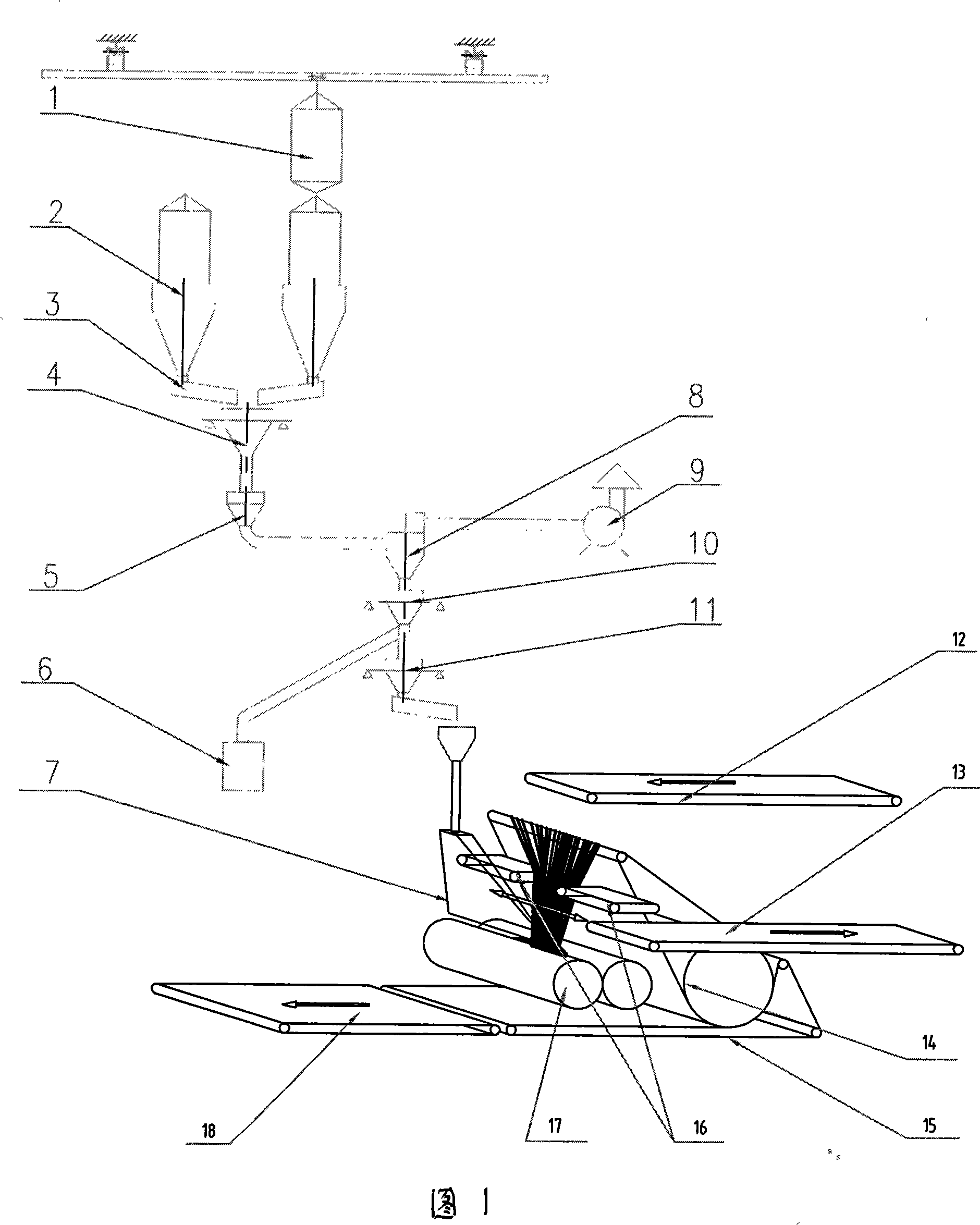

[0015] In Figure 1, the rubber material is added to the roller 17 of the open mill from the upper process through the glue adding device 12 to start rubber mixing. After the rubber material passes through the roll gap, it is caught by the automatic glue turning device and lifted to the top and then put into the roll gap. In this way, the rubber material is continuously passed through the roller gap for rubber mixing. During this period, the automatic rubber stamping device also clamps the rubber material and moves left and right, so that the rubber material is mixed left and right to realize the rubber stamping function; After air delivery and checking, it reaches the weight reduction scale bucket 11, and is gradually fed into the mill through the electric vibration feeder 3 along the drug chute 7 above the mill to complete the automatic feeding process; after the rubber is refined, it passes through the rubber belt. The machine transports the rubber out.

[0016] The course o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com