Stainless steel treatment technique

A processing technology, stainless steel technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of great harm to human body and environment, decreased corrosion resistance of stainless steel, and traces left on the substrate, etc. To achieve the effect of less harm and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

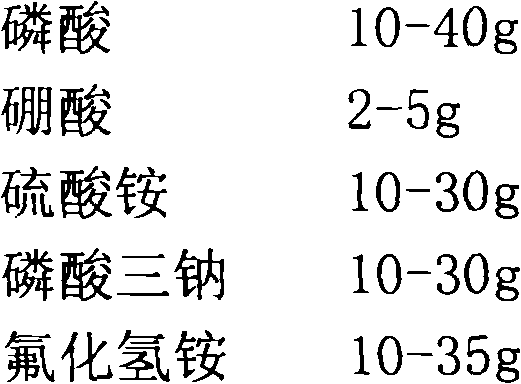

[0026] The stainless steel after chemical cleaning is contained in 4% (mass percentage) nitric acid, and concentration is respectively the this of 10g / L phosphoric acid, 2g / L boric acid, 10g / L ammonium sulfate, 10g / L trisodium phosphate and 10g / L ammonium bifluoride Soak in the stainless steel sealing solution for 10 minutes, the working temperature is 55 ℃, the stainless steel is silvery white after being taken out, then washed with water and air-dried, then immersed in 0.5% (mass percentage) CM-02 acrylic resin at room temperature for 2 seconds, and finally When it is taken out and baked, a protective film is formed on the surface of the stainless steel.

Embodiment 2

[0028] The stainless steel after chemical cleaning contains 10% (mass percentage) nitric acid, and concentration is respectively the this of 40g / L phosphoric acid, 5g / L boric acid, 30g / L ammonium sulfate, 30g / L trisodium phosphate and 35g / L ammonium bifluoride Soak in the stainless steel sealing solution for 35 minutes, the working temperature is 85 ℃, the stainless steel is silvery white after taking it out, then wash with water and air dry, then soak in 5% (mass percentage) CM-02 acrylic resin at room temperature for 30 seconds, and finally When it is taken out and baked, a protective film is formed on the surface of the stainless steel.

[0029] Above, the thickness of the protective film is related to the concentration of CM-02 acrylic resin and soaking time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com