Flat-plate windmill

A technology of flat panels and windmills, which is applied in wind power engines, wind power motor combinations, wind power generator components, etc., and can solve problems such as difficult high power output and low wind energy receiving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

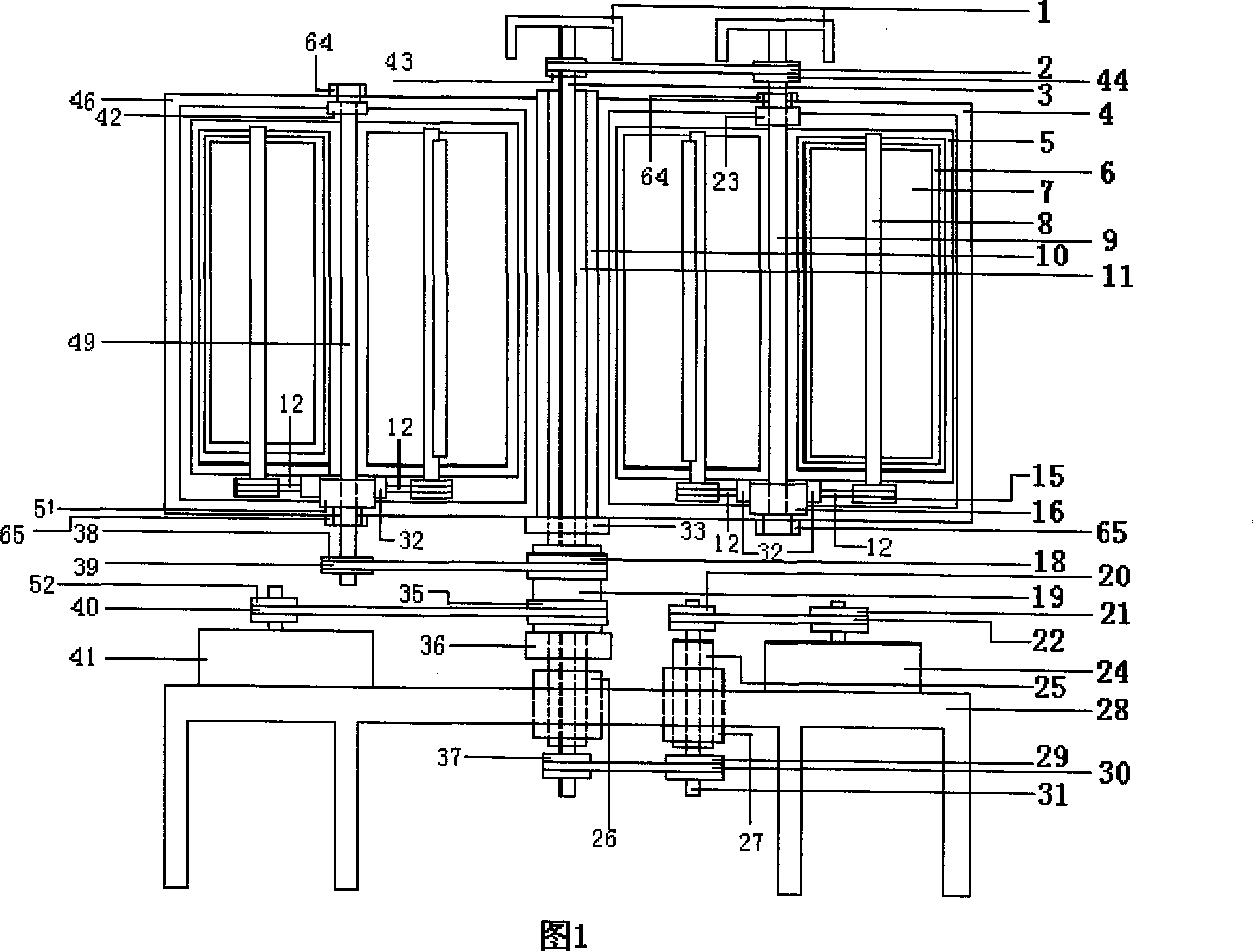

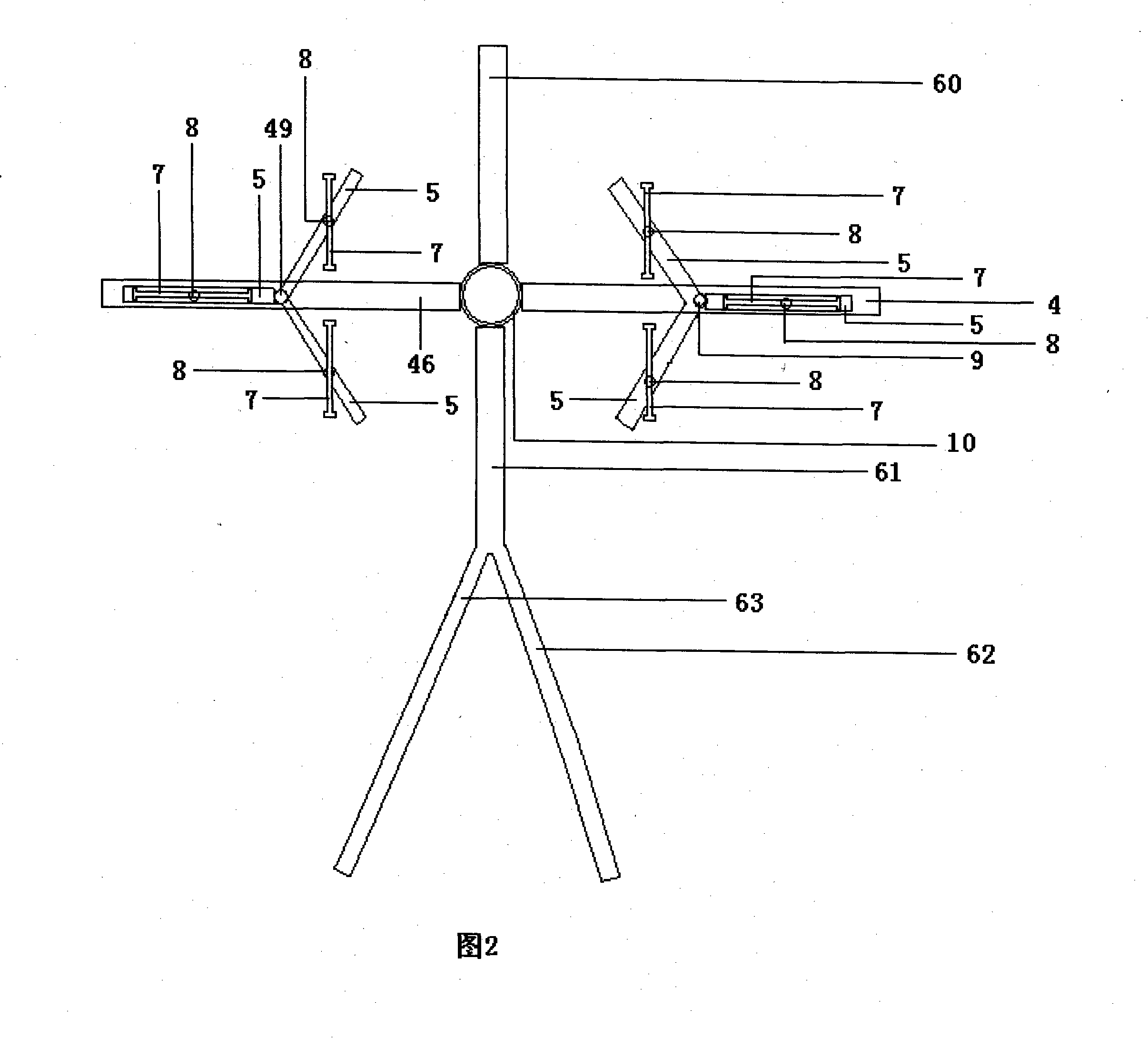

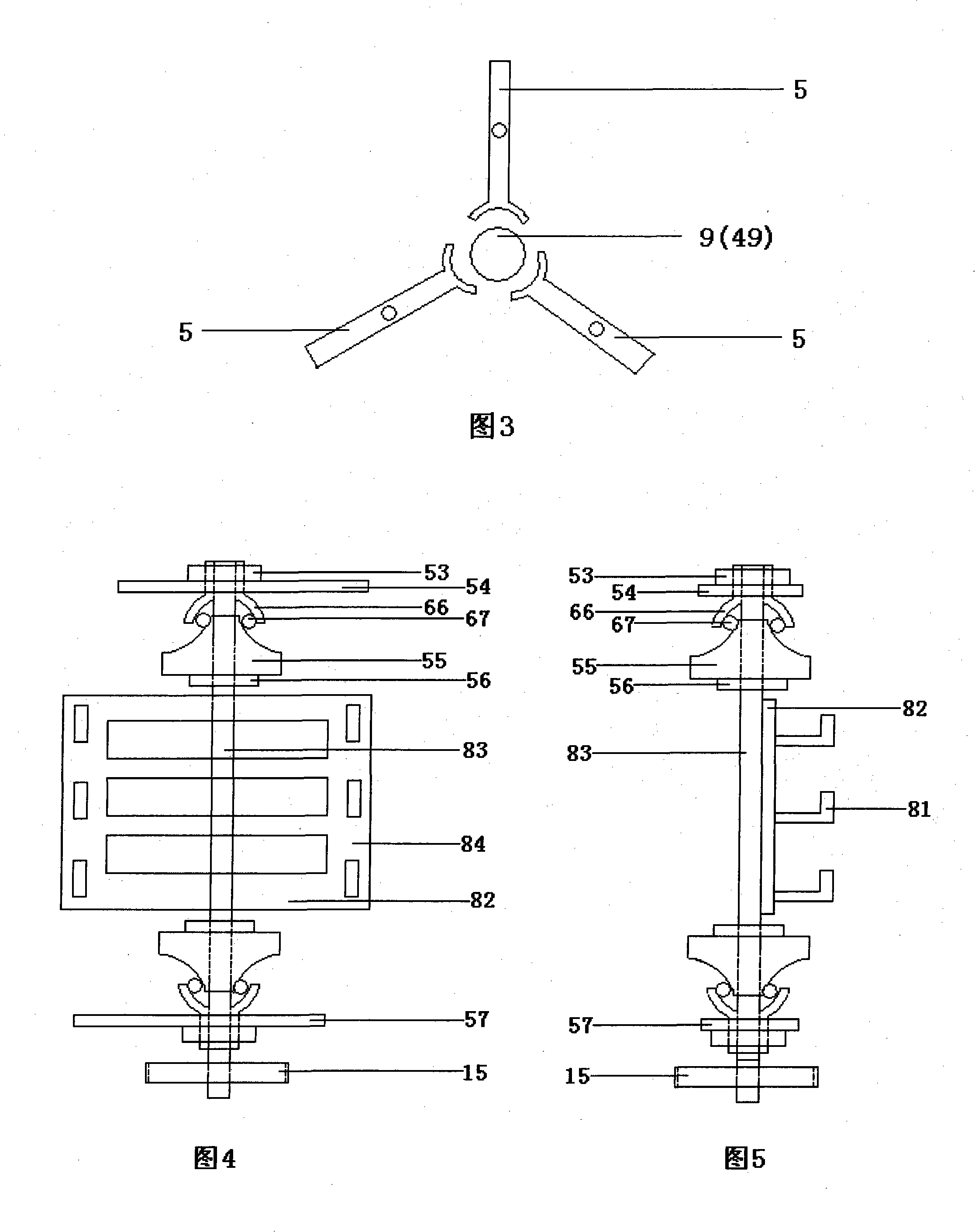

[0084] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

[0085] The overall composition of the flat windmill of the present invention includes six wind panels, six wind panel rotation shafts, six wind panel gears, six fast and slow two-speed gear boxes, six wind panel frames, and twelve wind panel rotation shaft shaft stops. Twelve wind panel rotation shaft bead bowls, two wind direction frames, two output shafts, two output shaft gears, four output shaft shaft stops, two output shaft bead bowls, two bead bowl gears, four drive shafts Shaft block, four transmission shaft bead bowls, one wind direction sleeve, one output sleeve, two bearings between the output sleeve and the main pipe, two sleeve gears, eleven chains, one long transmission shaft, one short transmission shaft Shaft, four transmission shaft gears, two wind direction plates, two sub-wind direction plates, a base, a mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com