Garlic-peeling machine inlet capable of cutting root function

A technology of feeding port and function, applied in the field of feeding port of garlic peeling machine, can solve the problems of low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

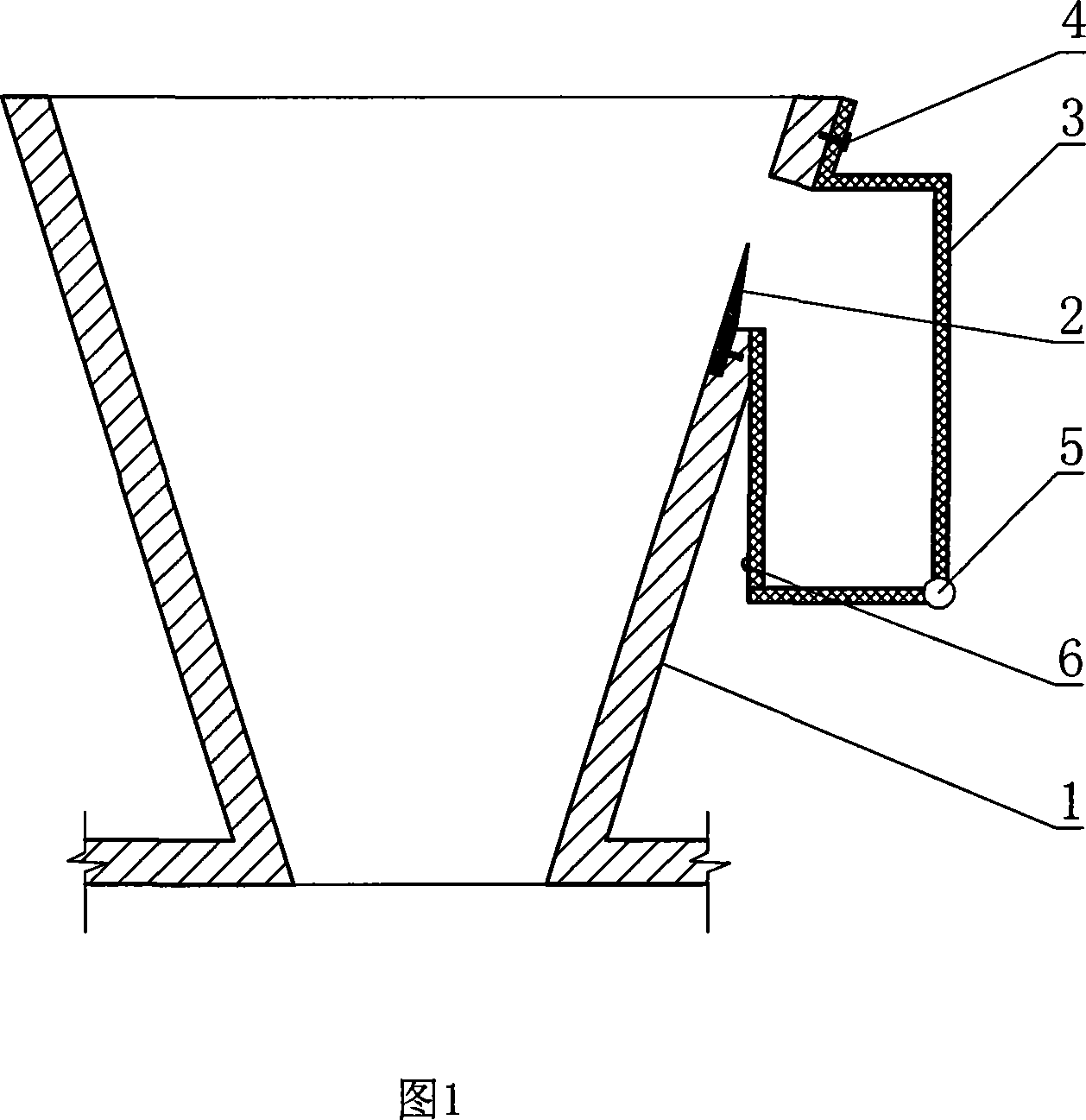

[0011] The feeding port of the garlic peeling machine with root cutting function is composed of hopper 1, blade 2, garlic root box 3, screw 4, rotating shaft 5 and buckle 6. There is a hole with a diameter of 2cm on the side wall of the hopper 1. A blade 2 is attached to the inner wall of the hopper 1 and has a length of 1 / 2 in the hole at the lower edge of the hole. There is a hole on the outer wall of the hopper 1 that is connected to the hopper through a screw. 4 connected garlic root boxes3. Garlic root case 3 bottoms have the cover plate that links to each other by rotating shaft 5, and cover plate links to each other with hasp 6 with the lower mouth of garlic root case. When the garlic enters the hopper 1, the operator only needs to slide the garlic root against the hole on the inner wall of the hopper 1 from top to bottom, and the garlic root will be cut off by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com