Building concrete core drilling machine

A technology of drilling coring and concrete, which is applied in the direction of earthwork drilling, drilling equipment, and undisturbed core extraction devices, etc. It can solve the problems of sewage splashing, dirtying staff clothes, and affecting the quality of coring, so as to ensure the quality of coring quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

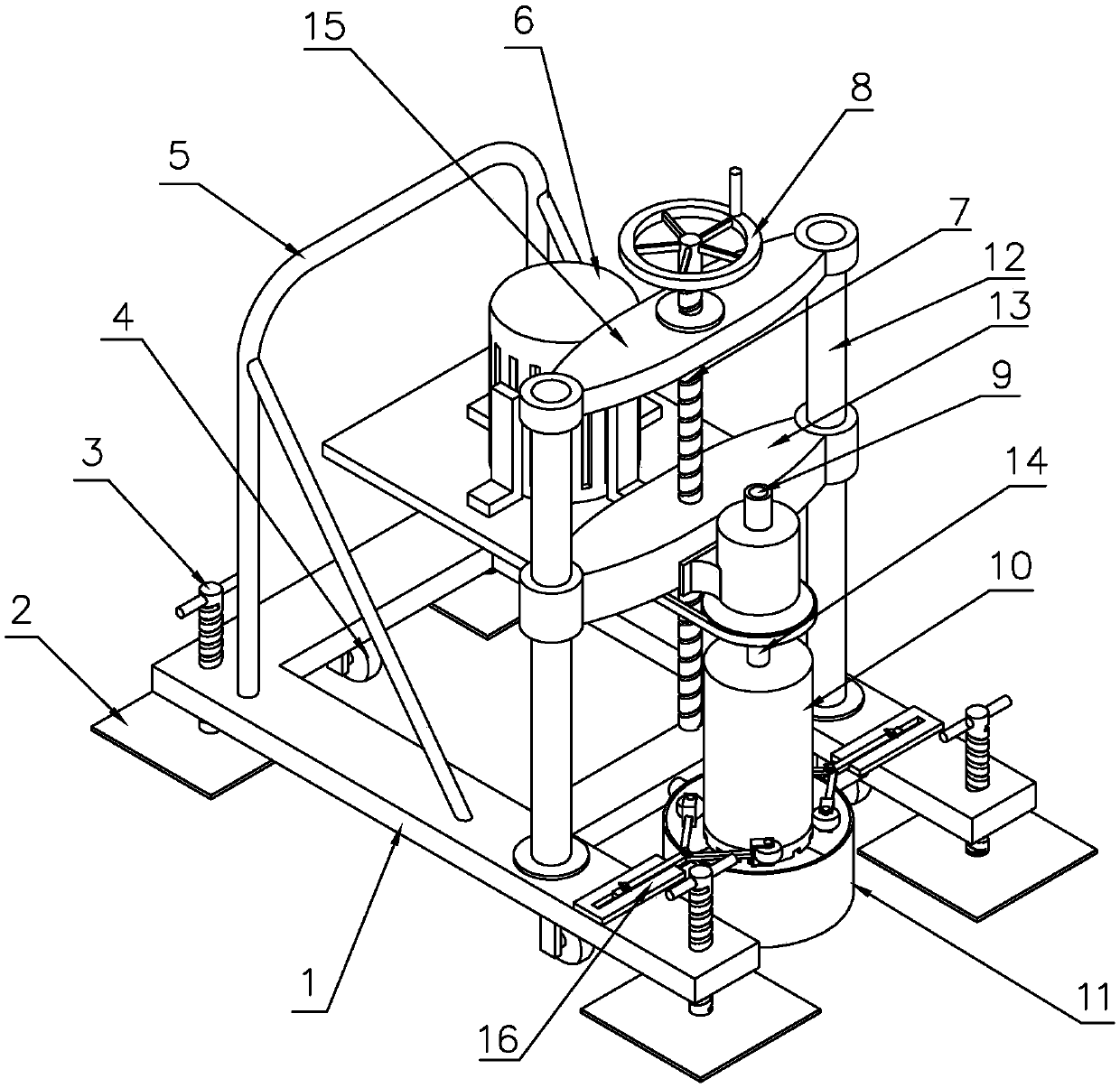

[0016] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-2 , to further specifically describe the technical solution of the present invention.

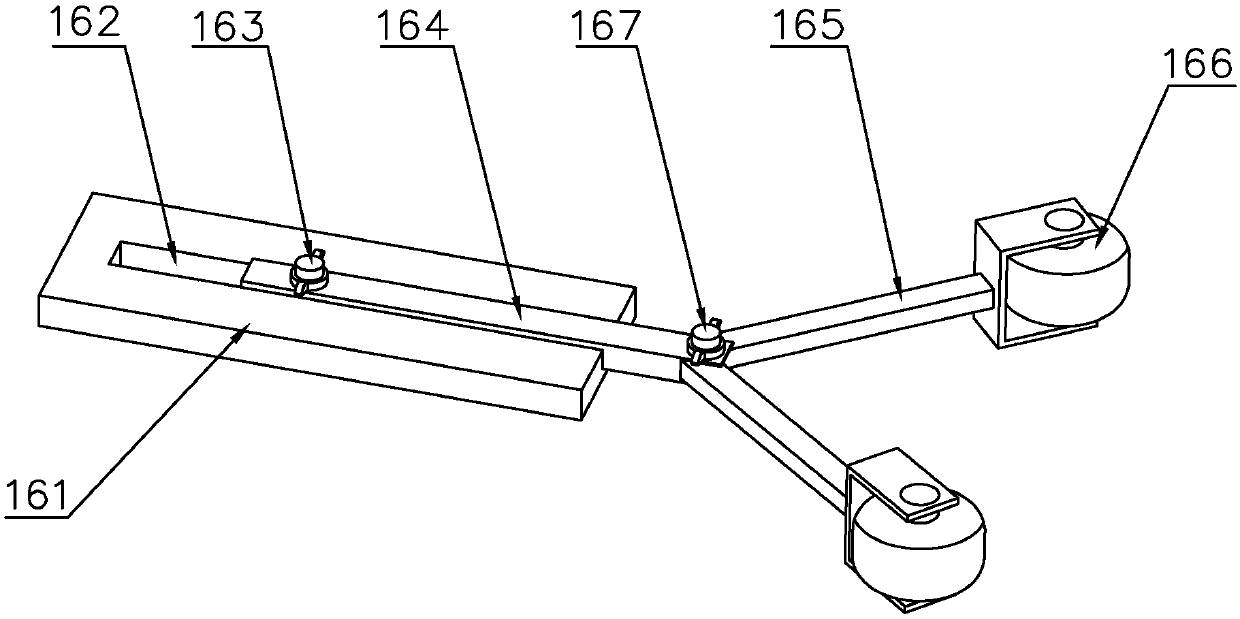

[0017] A concrete drilling and coring machine for construction, including a frame 1, a backing plate 2, a ground wheel 4, a motor 6, a transmission shaft 14, a guide rod 12, an upper beam 15, a sliding frame 13, a core bit 10, a clamping Device 16, the ground wheel 4 is provided on the lower side of the frame 1 to facilitate the movement of the drilling and coring machine, a clamping device 16 is provided on one side of the frame 1, and several lead screws are provided on the frame 1 I3, the underside of the lead screw I3 is provided with a backing plate 2, the upper side of the frame 1 is provided with a guide rod 12, the top of the guide rod 12 is provided with an upper beam 15, and one side of the upper beam 15 is provided with a wire Rod II7, the top of the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com