Medical jiggle lag screw for medicine

A technology of screw and pulling force, which is applied in the field of medical micro-motion lag screws, and can solve the problems of easy breakage of screws and difficulty in taking out broken screw bone round needles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

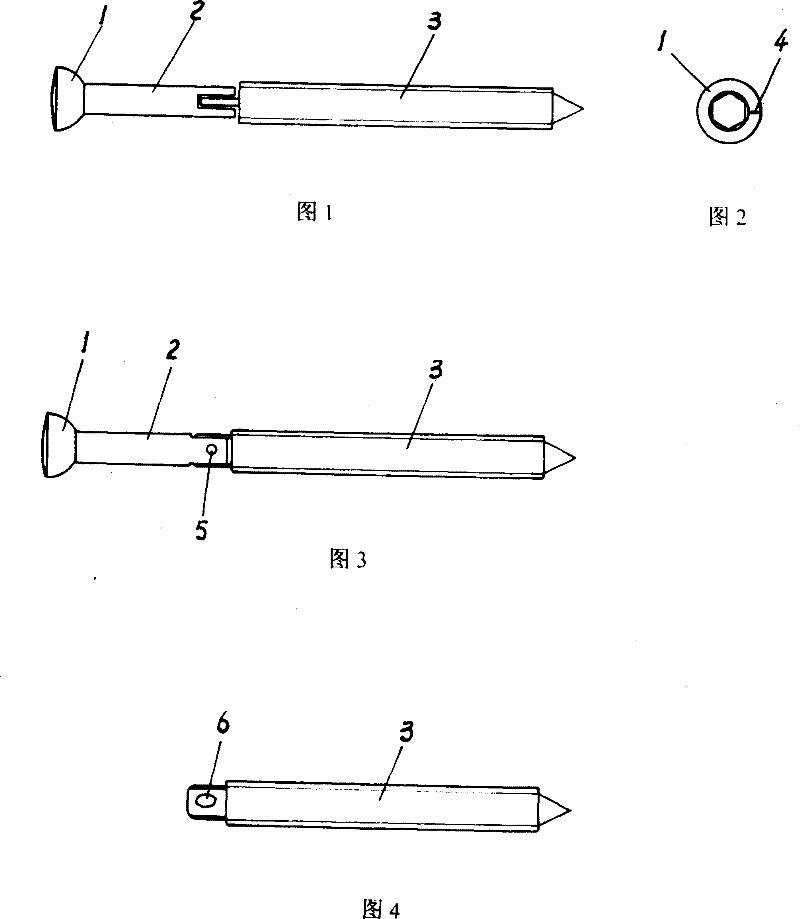

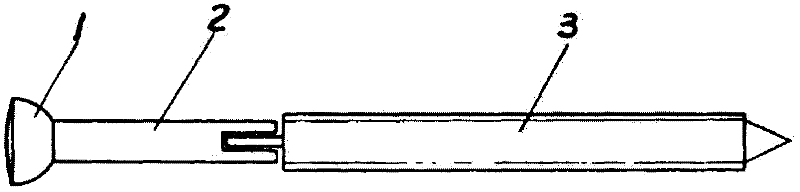

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings of the embodiments.

[0017] Referring to the accompanying drawings, the medical micro-motion lag screw provided by the present invention is an improvement on the basis of the existing locking nail, and its external structure size is the same as that of the original screw, with a rod diameter of 2.4-3 mm and a rod length of 50 mm. In the present invention, the screw rod of the screw is divided into two parts, and then the two parts are hinged together by a hinge shaft. As shown in the figure, there is no screw thread on the first section screw rod 2 that is made as one with the screw head 1, and the tail section screw rod 3 hinged with the first section screw rod 2 is full thread. Position mark 4 notches are set on the screw head 1 . The axis orientation of the hinge shaft 5 can be determined with reference to the positioning mark 4 . That is, when the screw i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com