Terminal aldehyde hyper branched polymer leather retanning agent and preparation method thereof

A technology of hyperbranched polymer and terminal hydroxyl hyperbranching, which can be used in small hide/big hide/leather/fur treatment, small hide/big hide/leather/fur chemical treatment, tanning treatment, etc. Obvious, large usage, low reactivity and other problems, to achieve the effect of high reactivity, small usage, and improved tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

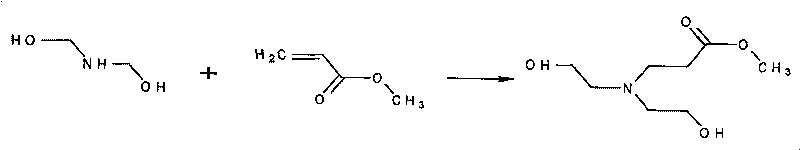

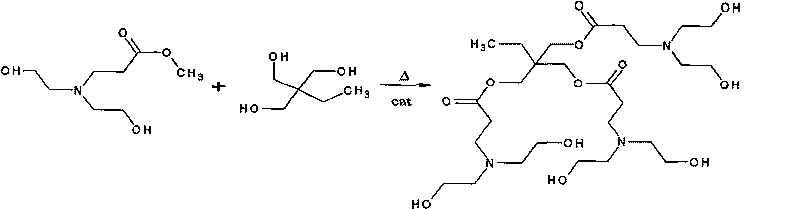

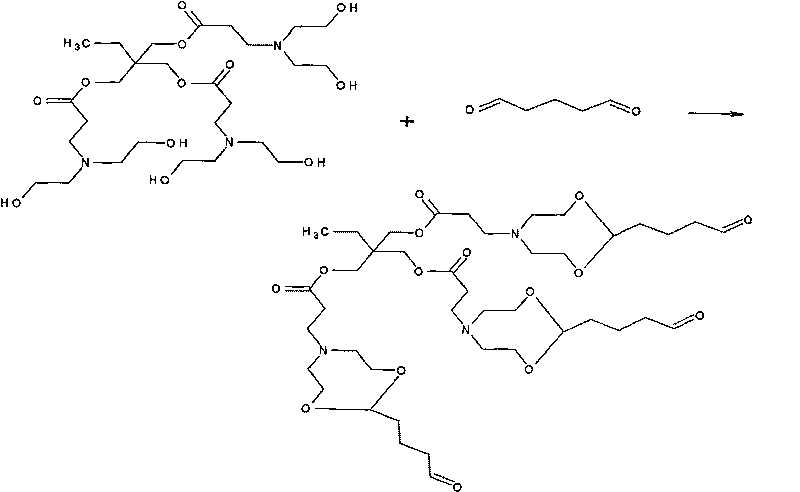

[0009] First, methyl acrylate and diethanolamine were mixed at a molar ratio of 1:1.3, and 20 mL of anhydrous methanol was added as a solvent. After the reaction was stirred at 35 °C for 7 h, the solvent was removed under reduced pressure, and 4% by mass of p-toluenesulfonic acid was added. Acid catalyzed by acid, vacuumed at 120°C (vacuum degree of 0.05MPa) and reacted for 3h to obtain hydroxyl-terminated hyperbranched polyamine-ester; Distillation to remove water) mix at a molar ratio of 2:1, add concentrated sulfuric acid with a mass percentage of 2%, add 35 ml of cyclohexane, and stir and react at 100 ° C for 3 h.

[0010] The reaction scheme is as follows:

[0011] (1) Synthesis of methyl acrylate and diethanolamine

[0012]

[0013] (2) Synthesis of hydroxyl-terminated hyperbranched polyamine-ester

[0014]

[0015] (3) Synthesis of aldehyde-terminated hyperbranched polymer leather retanning agent

[0016]

Embodiment 2

[0018] First, ethyl acrylate and diisopropanolamine were mixed at a molar ratio of 1:1.8, and 30 mL of absolute ethanol was added as a solvent. After stirring and reacting at 30 °C for 5 h, the solvent was removed under reduced pressure, and ethyl acrylate and diisopropanol were added. The concentrated sulfuric acid containing 3% of the total mass of propanolamine was subjected to acid catalysis, and the reaction was carried out under vacuum at 130 ° C (the vacuum degree was 0.1 MPa) for 2 h to obtain the hydroxyl-terminated hyperbranched polyamine-ester; the hydroxyl-terminated hyperbranched polyamine-ester was The hydroxyl group and glutaraldehyde (distilled to remove water before use) are mixed in a molar ratio of 2.5:1, add 4% p-toluenesulfonic acid of the total mass of the reactant, add 50 mL of cyclohexane with water agent, and stir the reaction at 120 ° C 1.5h is enough.

Embodiment 3

[0020] First, butyl acrylate and diethanolamine were mixed at a molar ratio of 1:2.1, and 35 mL of anhydrous isopropanol was added as a solvent. After stirring and reacting at 40 °C for 3 h, the solvent was removed under reduced pressure, and ethyl acrylate and diisopropyl alcohol were added. The concentrated sulfuric acid containing 5% of the total mass of alkanolamine is acid catalyzed, and the reaction is carried out under vacuum at 100 ° C (the vacuum degree is 0.08 MPa) for 2.5 h to obtain the hydroxyl-terminated hyperbranched polyamine-ester; the hydroxyl-terminated hyperbranched polyamine-ester is The hydroxyl group and glutaraldehyde (water was distilled off before use) were mixed in a molar ratio of 2.1:1, dry HCl of 3% of the total mass of the reactant was added, 40 mL of cyclohexane with water was added, and the reaction was stirred at 140 ° C for 0.5 h That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com