Function additive for improving sanitation performance of superfine fibre chemical leather and preparation method thereof

A technology of hygienic performance and functional additives, applied in the direction of fiber type, fiber treatment, textile and papermaking, etc., can solve the problems of poor hygienic performance of microfiber synthetic leather, and achieve high end group functionality, water vapor permeability and moisture absorption. The effect of improving water vapor permeability and hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A functional auxiliary agent for improving the hygienic performance of superfine fiber synthetic leather, which is made by the following preparation method: the preparation method includes the following steps in sequence

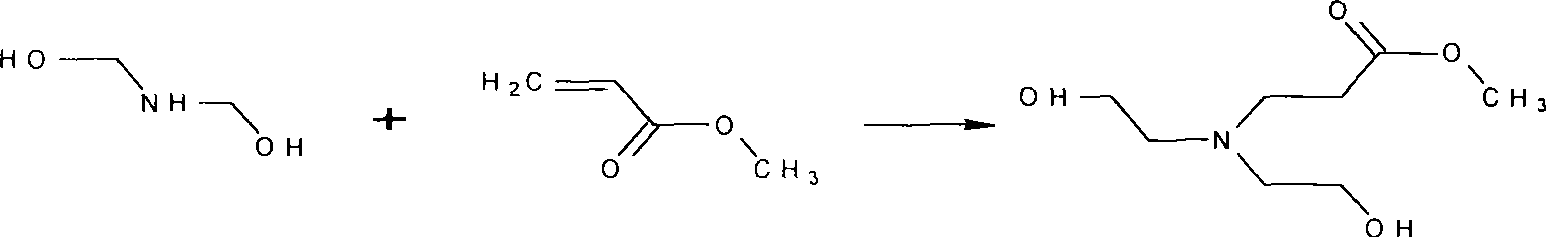

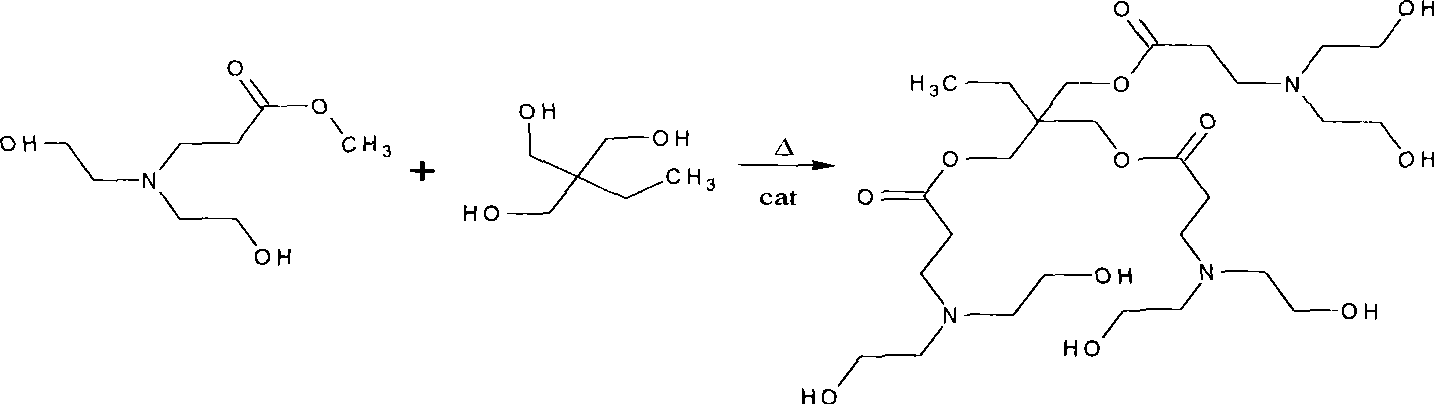

[0022] Step 1: Mix diethanolamine and methyl acrylate at a molar ratio of 1:1, add 20 mL of anhydrous methanol as a solvent, stir and react at 35°C for 4 hours, vacuumize the obtained product to remove the solvent, and set aside;

[0023] Step 2: adding 4% p-toluenesulfonic acid to the total mass of reactants for acidic catalysis, and reacting at 120° C. for 3 hours under vacuum (vacuum degree: 0.05 MPa), to prepare hydroxyl-terminated hyperbranched polyamide-ester.

Embodiment 2

[0025] A functional auxiliary agent for improving the hygienic performance of superfine fiber synthetic leather, which is made by the following preparation method: the preparation method includes the following steps in sequence

[0026] Step 1: Mix diisopropanolamine and ethyl acrylate at a molar ratio of 1:1.5, add 30mL of absolute ethanol as a solvent, stir and react at 30°C for 5 hours, transfer the obtained product directly into a vacuum bottle, and pump After removing the solvent in vacuo, set aside:

[0027] Step 2: add concentrated sulfuric acid with 3% of the total mass of the reactants for acidic catalysis, and react under vacuum at 130°C (vacuum degree: 0.1MPa) for 2h to prepare hydroxyl-terminated hyperbranched polyamide-ester.

Embodiment 3

[0029] A functional auxiliary agent for improving the hygienic performance of superfine fiber synthetic leather, which is made by the following preparation method: the preparation method includes the following steps in sequence

[0030] Step 1: Mix diethanolamine and butyl acrylate at a molar ratio of 1:2.5, add 35mL of anhydrous isopropanol as a solvent, stir and react at 40°C for 3 hours, remove the solvent from the obtained product, and set aside:

[0031] Step 2: add dry HCl with 3% of the total mass of the reactants for acidic catalysis, and perform a vacuum (vacuum degree of 0.08 MPa) reaction at 130° C. for 2.5 hours to obtain a hydroxyl-terminated hyperbranched polyamide-ester;

[0032] Step 3: Mix the hydroxyl groups in the hydroxyl-terminated hyperbranched polyamide-ester with maleic anhydride at a molar ratio of 2.1:1, add p-toluenesulfonic acid with a mass percentage of 3%, and stir and react at 180°C for 2.5h That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com