Terminal aldehyde hyper branched polymer leather retanning agent and preparation method thereof

A technology of hyperbranched polymer and hydroxyl-terminated hyperbranching, which can be used in small raw hides/large raw hides/leather/fur treatment, small raw hides/large raw hides/leather hides/fur chemical treatment, tanning treatment, etc. Large, low reactivity, insignificant effects, etc., to achieve the effect of small usage, high reactivity, and improved tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Firstly, methyl acrylate and diethanolamine were mixed at a molar ratio of 1:1.3, 20 mL of anhydrous methanol was added as a solvent, and after stirring and reacting at 35°C for 7 hours, the solvent was removed under reduced pressure, and p-toluenesulfonate with a mass percentage of 4% was added Carry out acidic catalysis with acid, vacuumize (vacuum degree is 0.05MPa) and react at 120°C for 3h to obtain hydroxyl-terminated hyperbranched polyurethane-ester; ) were mixed at a molar ratio of 2:1, 2% concentrated sulfuric acid was added, 35ml cyclohexane was added, and the mixture was stirred and reacted at 100°C for 3h.

[0010] The reaction scheme is as follows:

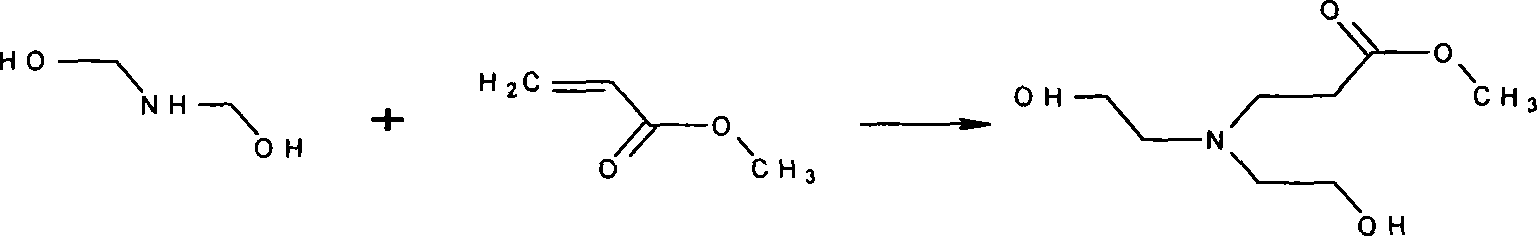

[0011] (1) Synthesis of methyl acrylate and diethanolamine

[0012]

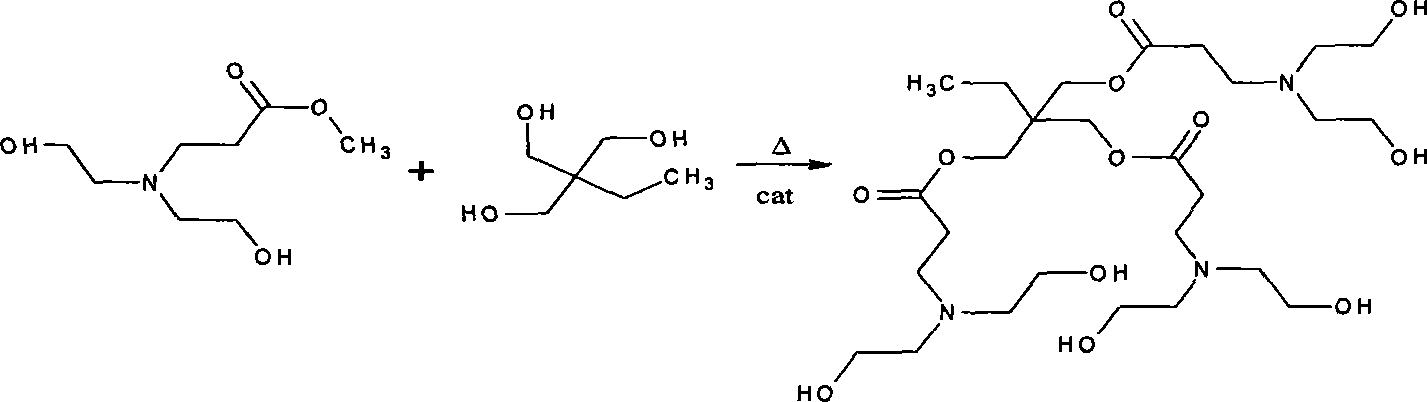

[0013] (2) Synthesis of hydroxyl-terminated hyperbranched polyurethane

[0014]

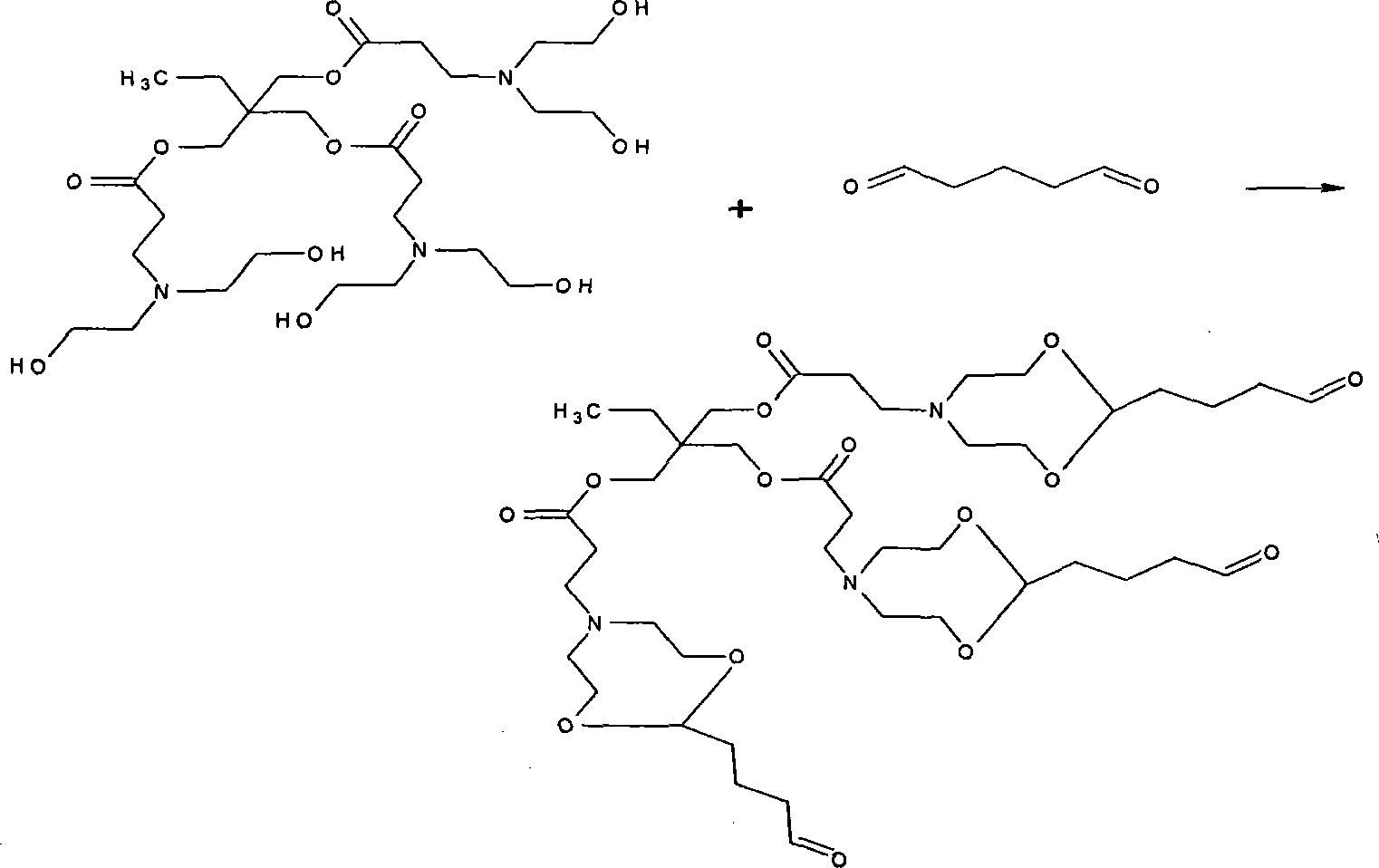

[0015] (3) Synthesis of aldehyde-terminated hyperbranched polymer leather retanning agent

[0016]

Embodiment 2

[0018] First, mix ethyl acrylate and diisopropanolamine at a molar ratio of 1:1.8, add 30 mL of absolute ethanol as a solvent, stir and react at 30°C for 5 hours, remove the solvent under reduced pressure, add ethyl acrylate and diisopropanolamine Concentrated sulfuric acid with 3% of the total mass of propanolamine is acid-catalyzed, and vacuumized (vacuum degree is 0.1MPa) at 130° C. for 2 hours to obtain a hydroxyl-terminated hyperbranched polyamine-ester; the hydroxyl-terminated hyperbranched polyurethane is combined with Glutaraldehyde (distilled to remove water before use) was mixed at a molar ratio of 2.5:1, p-toluenesulfonic acid with a total mass of 4% of the reactants was added, 50mL of water-carrying agent cyclohexane was added, and the reaction was stirred at 120°C for 1.5h. Can.

Embodiment 3

[0020] First, mix butyl acrylate and diethanolamine at a molar ratio of 1:2.1, add 35 mL of anhydrous isopropanol as a solvent, stir and react at 40°C for 3 hours, remove the solvent under reduced pressure, add ethyl acrylate and diisopropyl The concentrated sulfuric acid of alcohol amine gross mass 5% carries out acidic catalysis, under 100 ℃ vacuumizes (vacuum degree is 0.08MPa) reaction 2.5h, makes terminal hydroxyl hyperbranched polyamine-ester; The hydroxyl of terminal hydroxyl hyperbranched polyurethane and Glutaraldehyde (distilled to remove water before use) was mixed at a molar ratio of 2.1:1, dry HCl of 3% of the total mass of reactants was added, 40mL of water-carrying agent cyclohexane was added, and the reaction was stirred at 140°C for 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com