A kind of self-emulsifying aqueous polyester emulsion and preparation method thereof

A water-based polyester and polyester technology, applied in the direction of polyester coatings, coatings, etc., to achieve the effects of easy promotion, easy access to sources, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

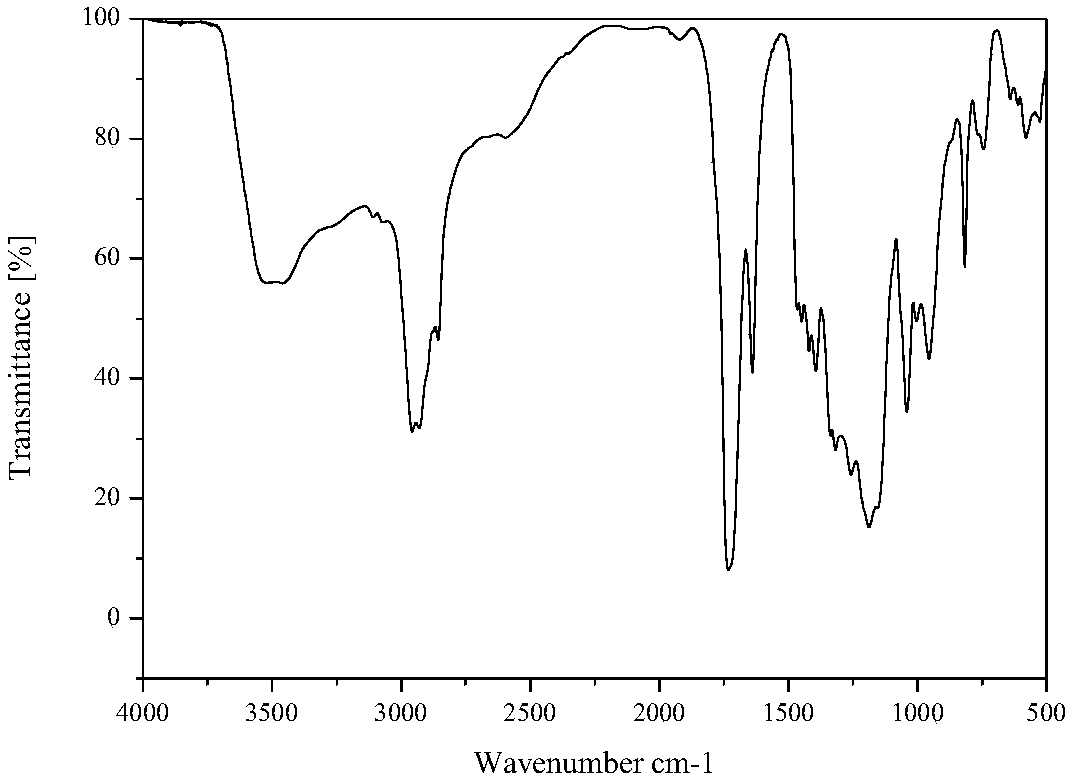

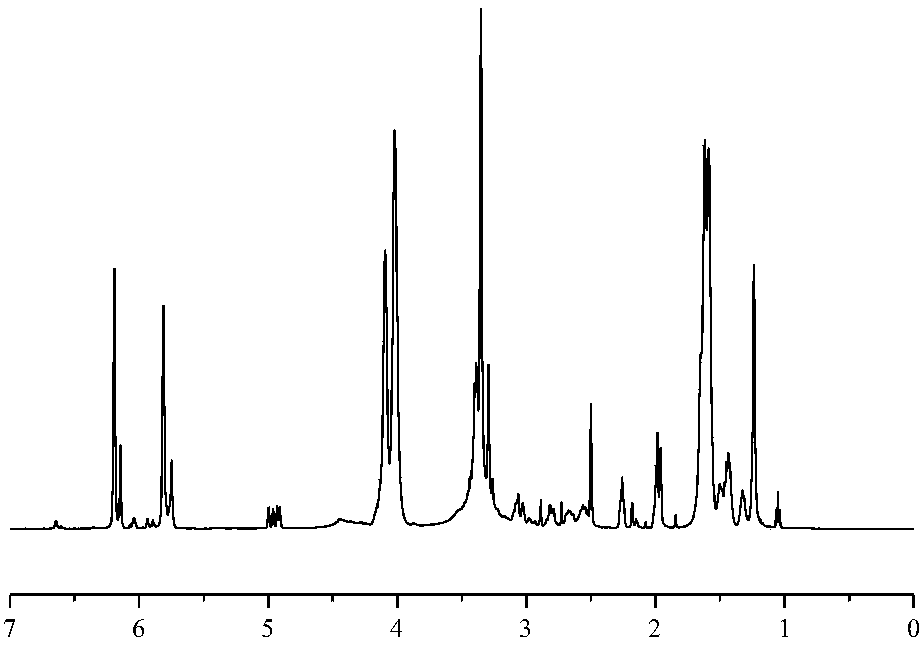

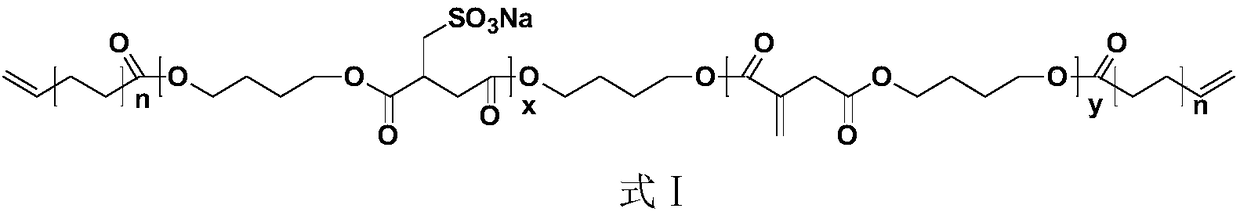

Image

Examples

Embodiment 1

[0033] Put methylene succinic acid, methyl succinic acid-5-sodium sulfonate, and 1,4-butanediol with a molar ratio of 1:0.2:1.25 in a 250ml four-necked flask, and add the catalyst methylene chloride Tin, the amount of which is added is 0.18% of the mass of methylene succinic acid, connected to the water separator, thermometer and stirrer, heated up to 180°C under the protection of nitrogen and vigorously stirred, when no more water is produced in the water separator After the esterification reaction was completed, the temperature was lowered to 160°C, and the pressure was reduced to -0.1Mpa to carry out the polycondensation reaction, and the reaction time was 3 hours. Hydroxyl-terminated poly(butylene itaconate-co-methylsuccinate-5-sodium butanediol sulfonate) ester (PBIINa) was obtained. Add undecylenic acid dropwise, the addition amount is 10% of the molar weight of 1,4 butanediol, under the protection of nitrogen, react at 160°C and stir vigorously for 1 hour to obtain unde...

Embodiment 2

[0035]Put methylene succinic acid, methyl succinic acid-5-sodium sulfonate, and 1,4-butanediol with a molar ratio of 1:0.2:1.25 in a 250ml four-necked flask, and add the catalyst methylene chloride Tin, the amount of which is added is 0.18% of the mass of methylene succinic acid, connected to the water separator, thermometer and stirrer, heated up to 180°C under the protection of nitrogen and vigorously stirred, when no more water is produced in the water separator After the esterification reaction was completed, the temperature was lowered to 160°C, and the pressure was reduced to -0.1Mpa to carry out the polycondensation reaction, and the reaction time was 3 hours. The hydroxyl-terminated PBIINa was obtained. Add undecylenic acid dropwise, the addition amount is 7% of the molar weight of 1,4 butanediol, under the protection of nitrogen, react at 110°C and stir vigorously for 5 hours to obtain undecylenic acid modified polyester . The polyester was added into water to prepa...

Embodiment 3

[0037] Put methylene succinic acid, methyl succinic acid-5-sodium sulfonate, and 1,4-butanediol with a molar ratio of 1:0.2:1.25 in a 250ml four-necked flask, and add the catalyst methylene chloride Tin, the amount of which is added is 0.18% of the mass of methylene succinic acid, connected to the water separator, thermometer and stirrer, heated up to 180°C under the protection of nitrogen and vigorously stirred, when no more water is produced in the water separator After the esterification reaction was completed, the temperature was lowered to 160°C, and the pressure was reduced to -0.1Mpa to carry out the polycondensation reaction, and the reaction time was 3 hours. The hydroxyl-terminated PBIINa was obtained. Add undecylenic acid dropwise, the amount added is 15% of the molar weight of 1,4 butanediol, under the protection of nitrogen, react at 140°C and stir vigorously for 4 hours to obtain undecylenic acid modified polyester . The polyester was added into water to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com