Car lamp control method and control circuit

A vehicle lamp control and vehicle lamp technology, which is applied in the direction of electric lamp circuit layout, energy saving control technology, electric light source, etc., can solve the problems of increasing the number of circuit board components, high failure rate, adverse effects on lines and life, and eliminates peak current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

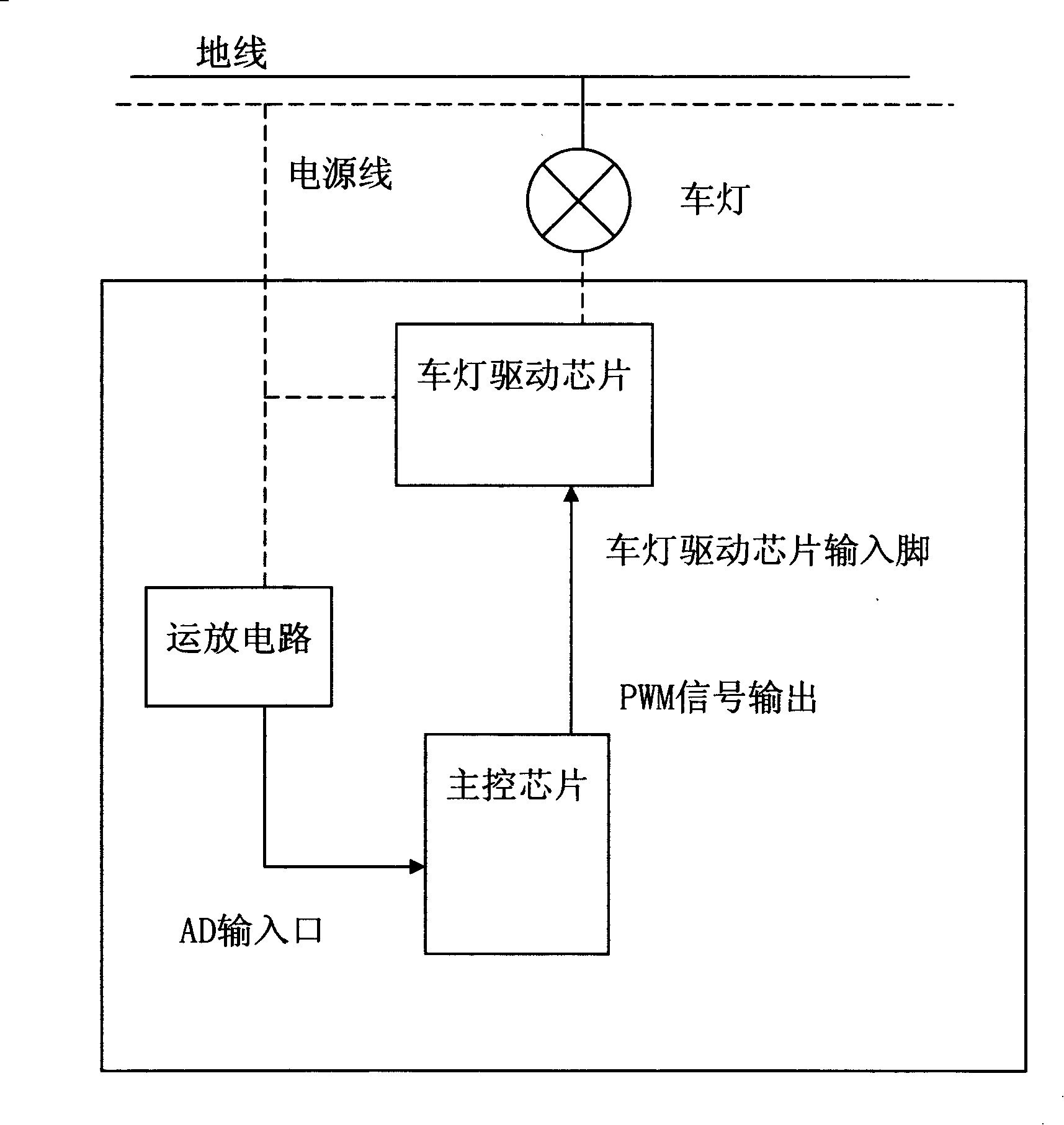

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] The car light control circuit shown in Figure 1 mainly includes two parts: the main chip and the car light driver chip. When the headlight lighting switch is turned on, the turn-on signal is transmitted to the main control chip, and the main control chip sends a PWM signal, that is, a pulse-width modulation signal (Pulse-Width-Modulation), to the input port of the light driver chip that controls the light. ;During the start-up process of the car light, the duty ratio of the PWM signal gradually increases according to a certain linear relationship with time, so that the voltage at both ends of the car light gradually increases until the voltage at both ends of the car light is equal to the rated voltage of the car light, and then remains at the car light Lamp rated voltage value. According to the load characteristics of the lights, within a certain per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com