Cast-in-situ hollow building roof construction method

A technology of hollow floor and construction method, which is applied in the direction of floors, building components, buildings, etc., and can solve the problems that are prone to not dense, easy to float, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

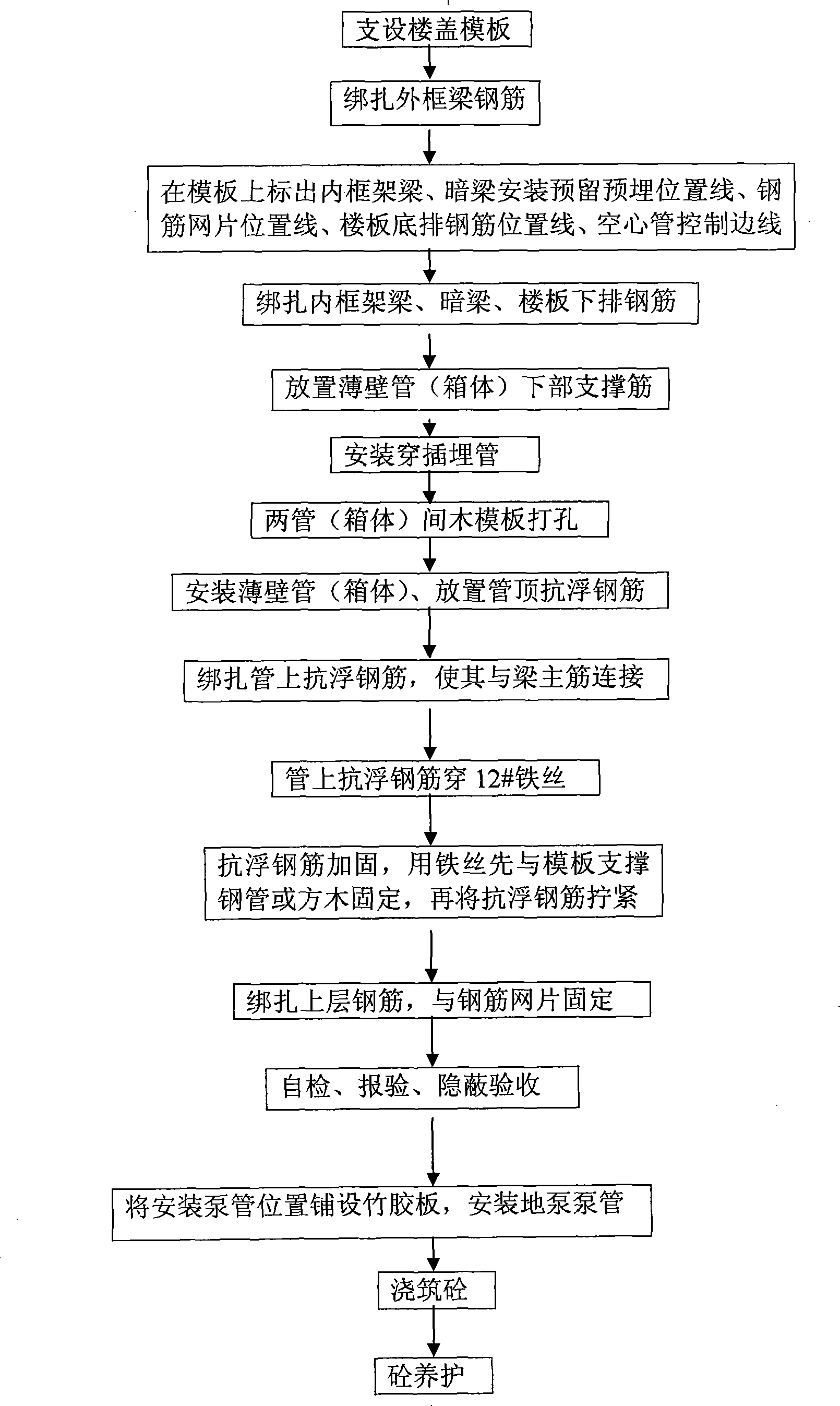

[0005] The present invention will be described in detail below in conjunction with the process flow diagram. Given by process flow chart, the present invention is realized by the following steps:

[0006] 1. Supporting floor formwork;

[0007] 2. Binding the steel bars of the outer frame beam;

[0008] 3. Mark the pre-embedded position lines reserved for the installation of inner frame beams and hidden beams, the position lines of steel mesh, the position lines of reinforcement bars at the bottom of the floor slab, and the control side lines of hollow pipes on the formwork;

[0009] 4. Binding inner frame beams, concealed beams, and steel bars under the floor;

[0010] 5. Place the supporting ribs at the lower part of the thin-walled pipe. After the bottom mesh steel bars are bound, place the supporting ribs at the lower part of the thin-walled pipes and connect them with the bottom bars of the beams. Set a 50mm thick concrete pad under the supporting ribs;

[0011] 6. Inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com