Method for the production of axially symmetrical workpieces with or without a toothed profile

A workpiece and contour technology, applied in the field of chipless production, can solve the problems of complex production process, expanding work consumption, etc., and achieve the effect of reducing cost, favorable fiber direction and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

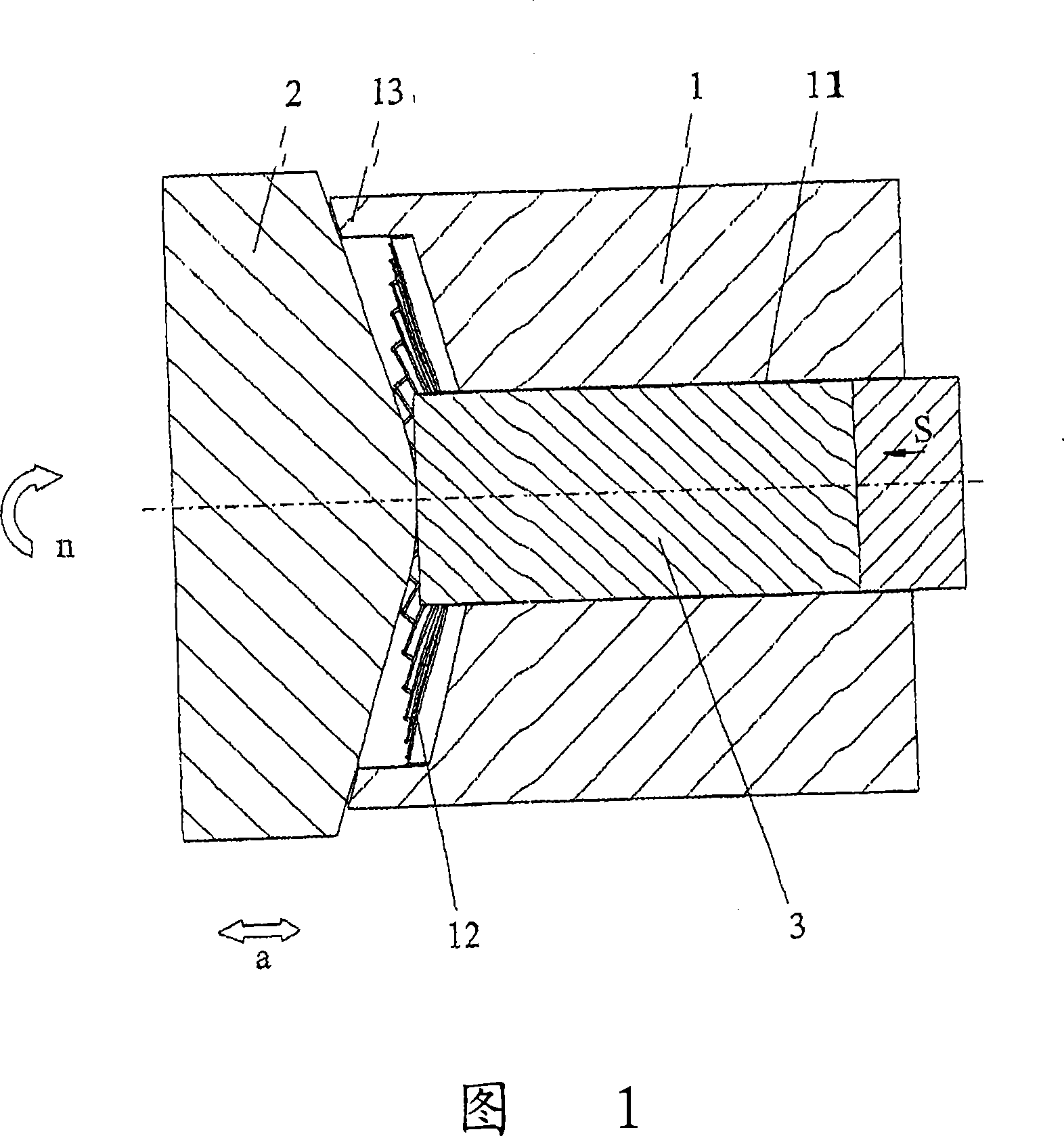

[0020] Figure 1 depicts a simplified construction of a press tool showing a die 1 and a press tool 2 placed thereon. The die has a bore 11 through its central axis, a tooth profile 12 and a boundary 13 on the side facing the press tool. The press tool rotates at a speed n, while the distance a between the press tool and the die can be adjusted by the feed movement. Under the action of the punch (not shown in the figure), the raw material 3 continuously enters the hole 11 (direction of arrow S) at a feed speed, from where the raw material is extruded to the die profile 12 and the press tool 2 in the space between. Through said pressing action, and the rotary movement of the presser acting on the raw material, the raw material flows radially outwards along the contour of the die until the raw material finally fills the shell of the die based on the boundary 13, and A finished workpiece is thus produced. Here too, the distance a can be adapted to the amount of raw material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com