Paper multi-feed detection apparatus and paper multi-feed detection method

A detection equipment, paper technology, applied in the direction of object supply, pile separation, function indication, etc., can solve the problems of restricting the configuration shape, increasing the cost of ultrasonic sensors, reducing the degree of freedom of design, etc., to prevent interference components, stabilize emission performance, The effect of improving reception performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

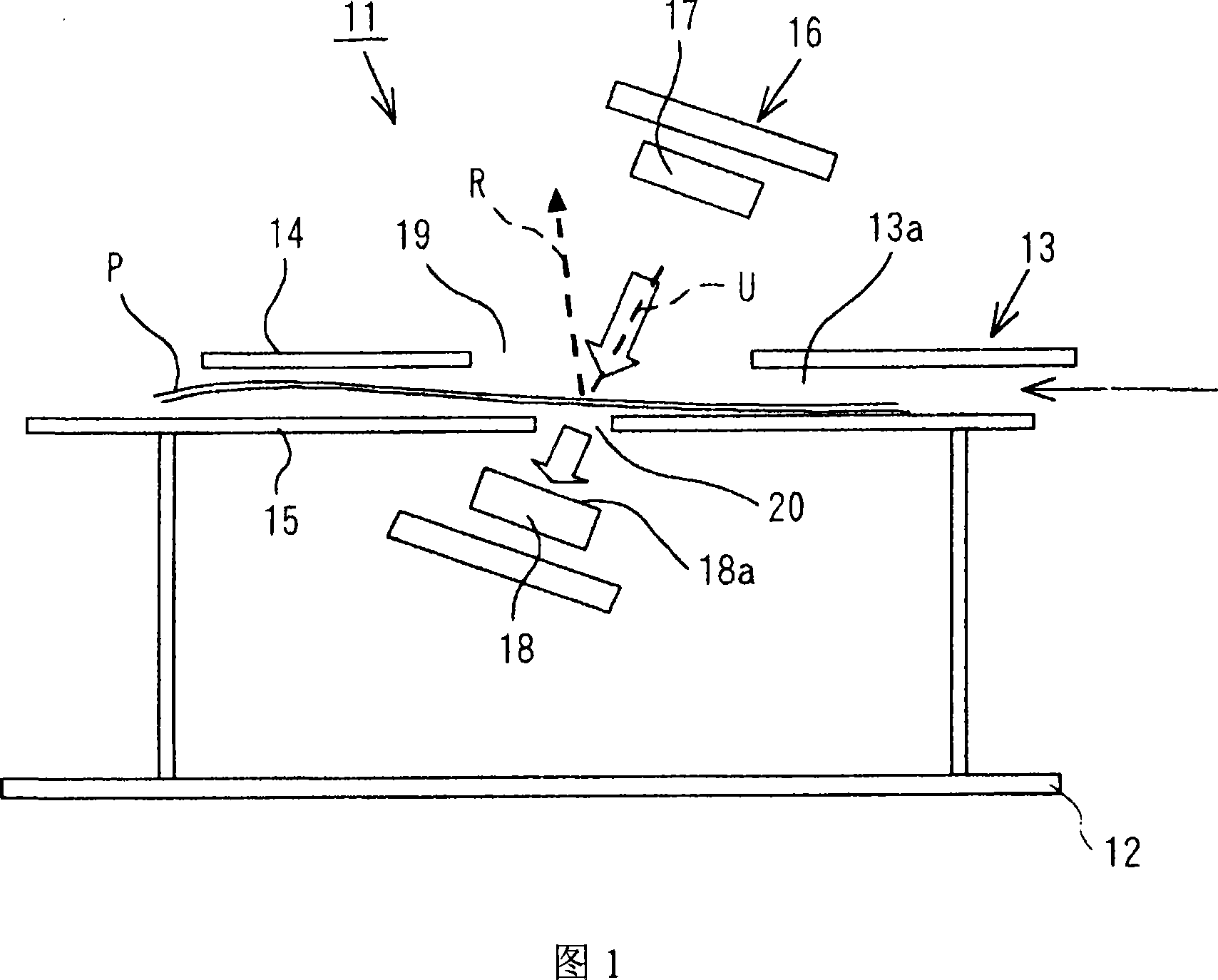

[0028] The accompanying drawing shows the built-in paper overlapping detection equipment of the copier. As shown in FIG. The conveyance passage 13 is covered by two conveyance guide plates 14 and 15 , an upper upper conveyance guide plate 14 and a lower lower conveyance guide plate 15 which are provided opposite to each other across a plane conveyance space 13 a.

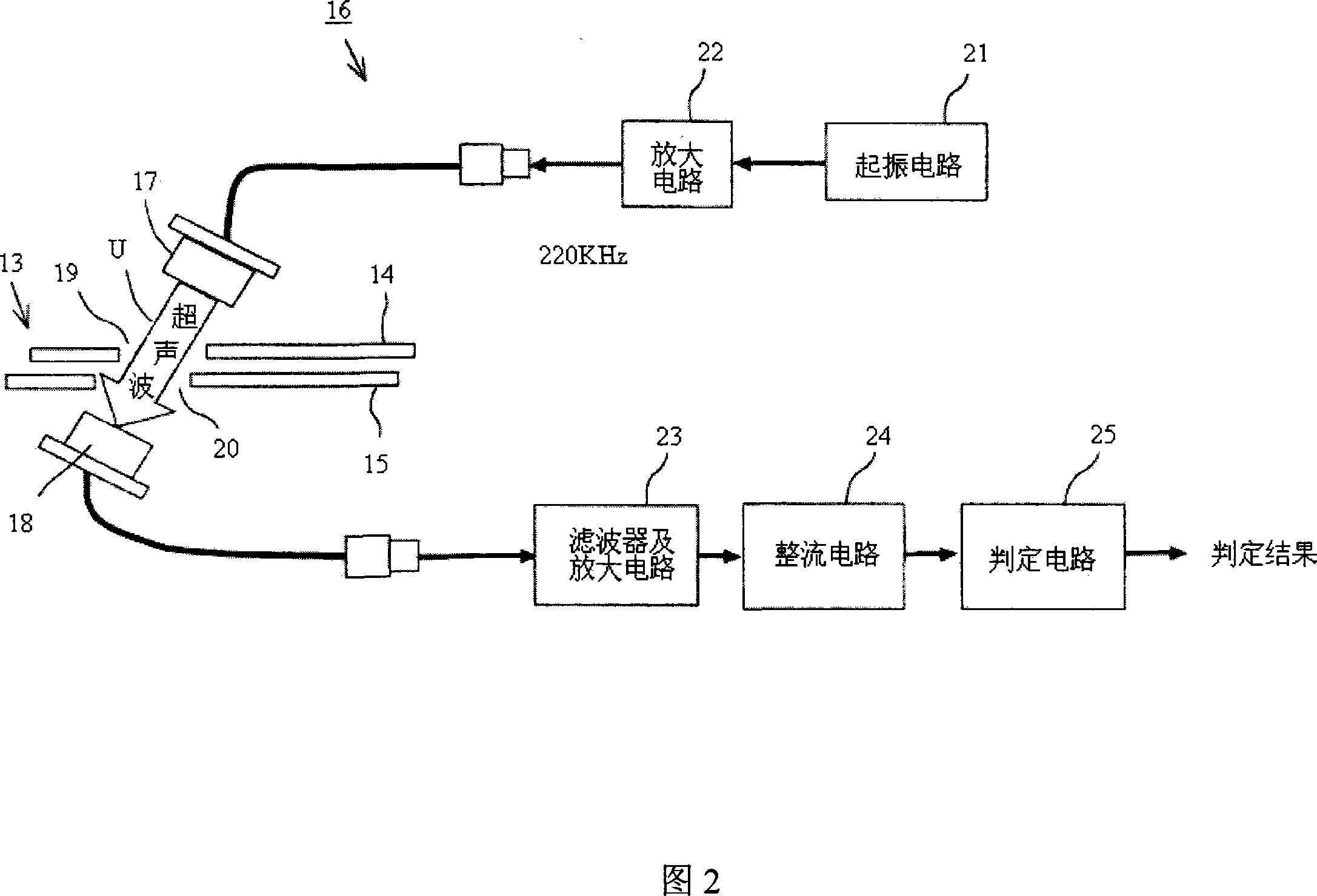

[0029] In addition, the transmitter 17 of the ultrasonic sensor 16 is provided above the transmission path 13 , and the receiver 18 of the ultrasonic sensor 16 is provided below, so that the transmitter 17 and receiver 18 face each other across the transmission path 13 . The above-mentioned ultrasonic sensor 16 is set to transmit and receive directions at a certain inclination angle, and adopts a configuration form suitable for transmitting and receiving ultrasonic waves U.

[0030] ...

Embodiment 2

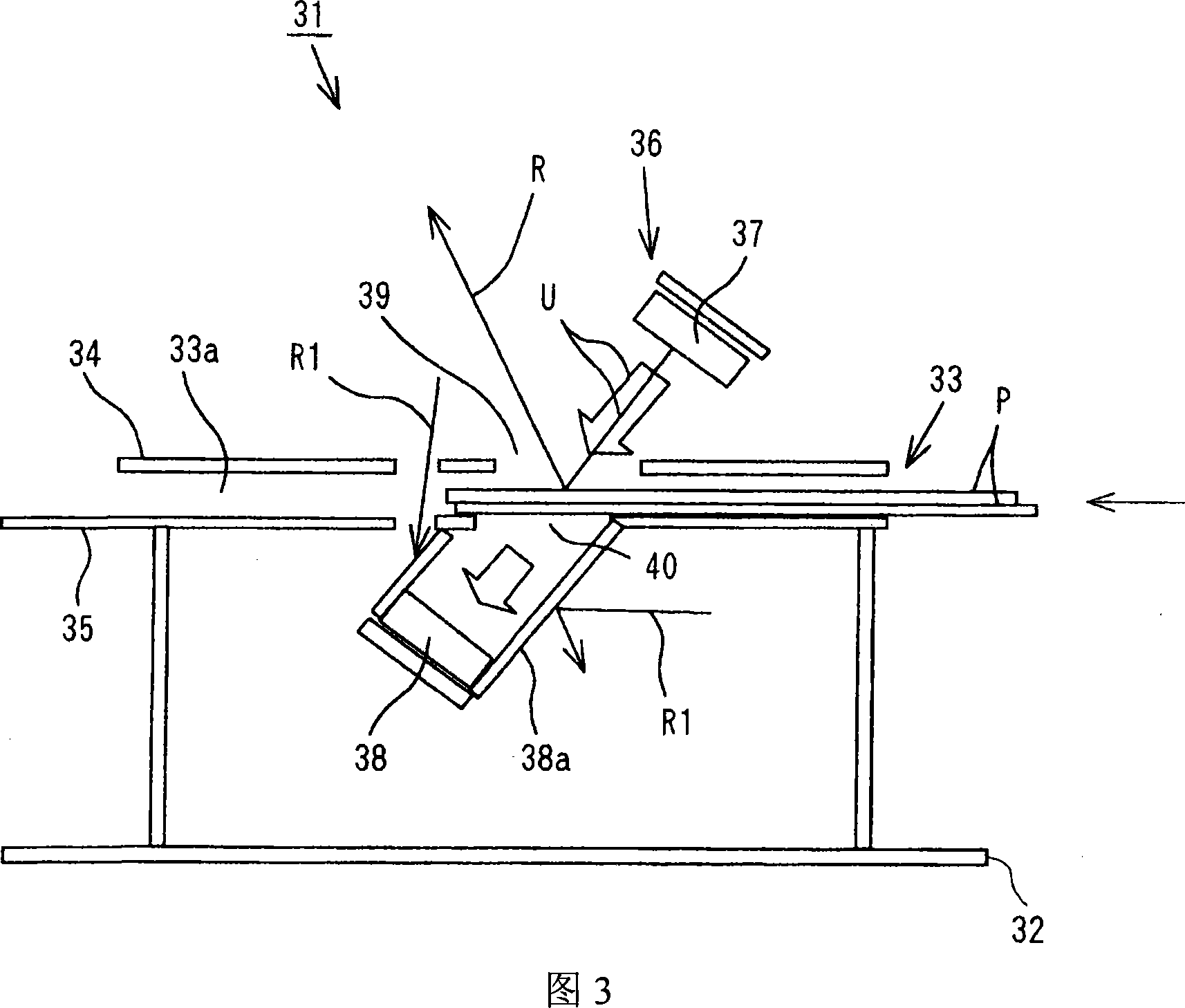

[0041] FIG. 3 shows an embodiment of another paper overlap detection device 31 . The copy paper overlap detection device 31 is provided with a conveying path 33 on the upper side of the device body 32 to convey the paper P planarly along the horizontal direction. The conveyance passage 33 is covered by two conveyance guide plates 34 , 35 , an upper upper conveyance guide plate 34 and a lower conveyance guide plate 35 which are arranged opposite to each other across a plane conveyance space 33 a.

[0042] In addition, the transmitter 37 of the ultrasonic sensor 36 is provided above the transmission path 33 , and the receiver 38 of the ultrasonic sensor 36 is provided below, so that the transmitter 37 and receiver 38 face each other across the transmission path 33 . The above-mentioned ultrasonic sensor 36 is set to transmit and receive directions at a certain inclination angle, and adopts a configuration form suitable for transmitting and receiving ultrasonic waves U.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com