Paper multi-feed detection apparatus and paper multi-feed detection method

一种检测设备、纸张类的技术,应用在物件供给、桩分离、功能指示等方向,能够解决限制配置形状、超声波传感器造价提高、降低设计自由度等问题,达到防止干扰成分、稳定发射性能、提高接收性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first embodiment of the present invention will be described in detail below with reference to the drawings.

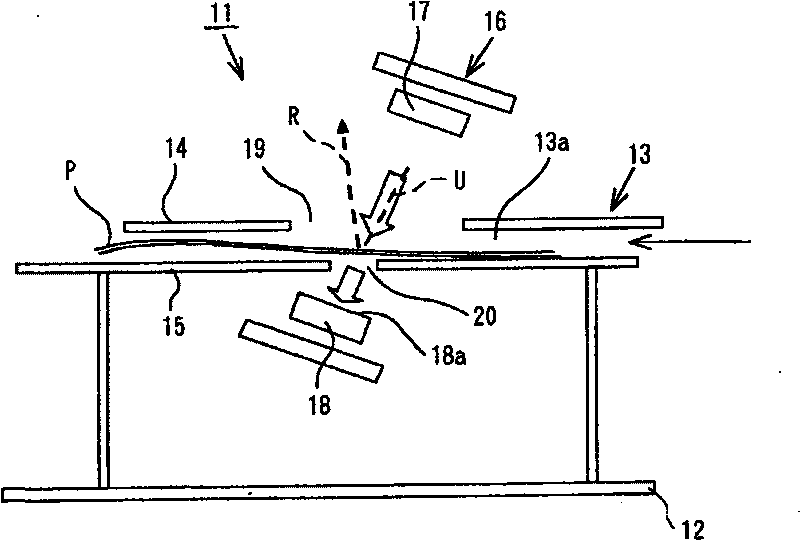

[0028] The picture shows the paper overlapped conveyance detection equipment built in the copier, such as figure 1 As shown, the above-mentioned paper overlapping conveyance detection device 11 is provided on the upper side of the device body 12 with a conveying path 13 for conveying the paper P in a horizontal direction. The conveying path 13 is covered by two conveying guide plates 14 and 15 of an upper upper conveying guide plate 14 and a lower lower conveying guide plate 15 that are provided opposite to each other with a flat conveying space 13a interposed therebetween.

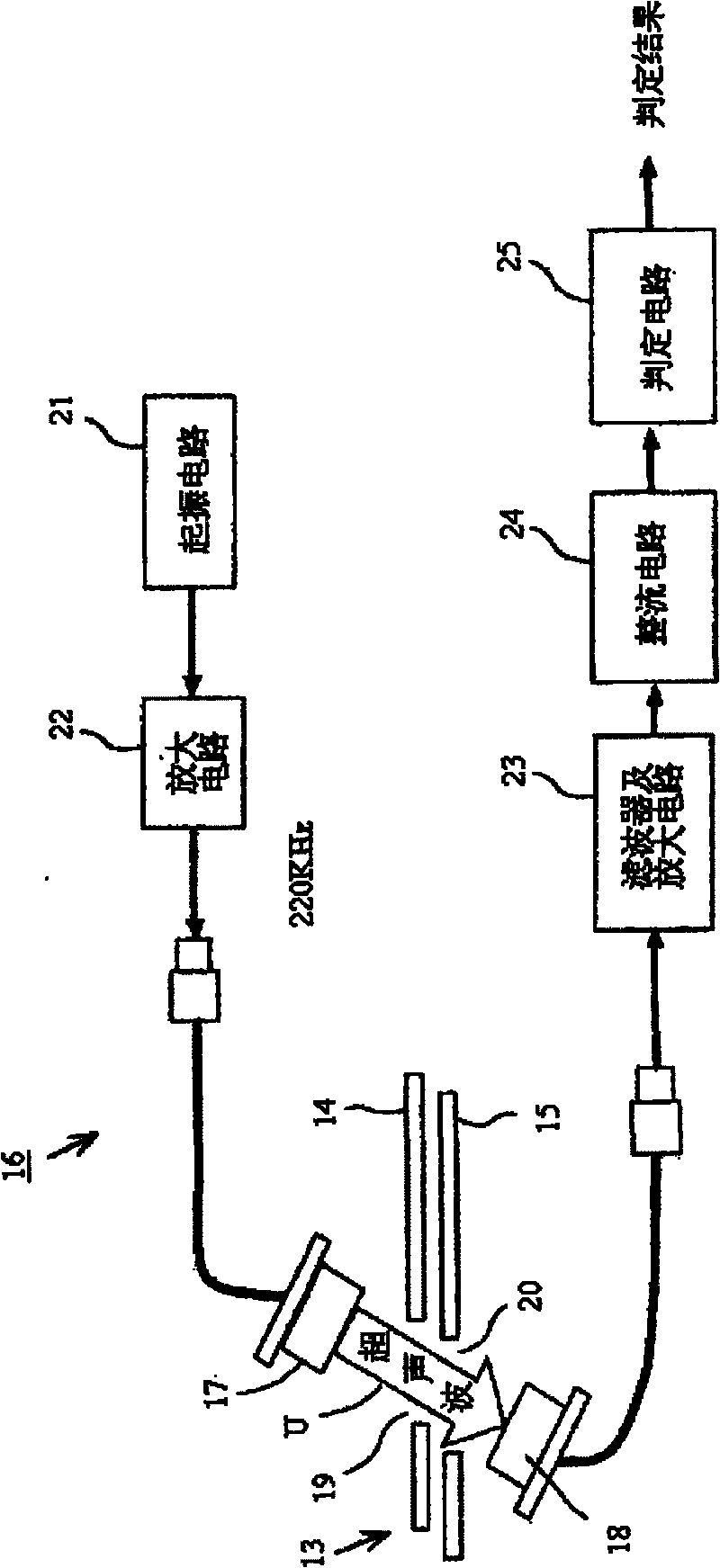

[0029] In addition, the transmitter 17 of the ultrasonic sensor 16 is installed above the transmission path 13, and the receiver 18 of the ultrasonic sensor 16 is disposed below, so that the transmitter 17 and the receiver 18 face each other across the transmission path 13. The above-mentio...

Embodiment 2

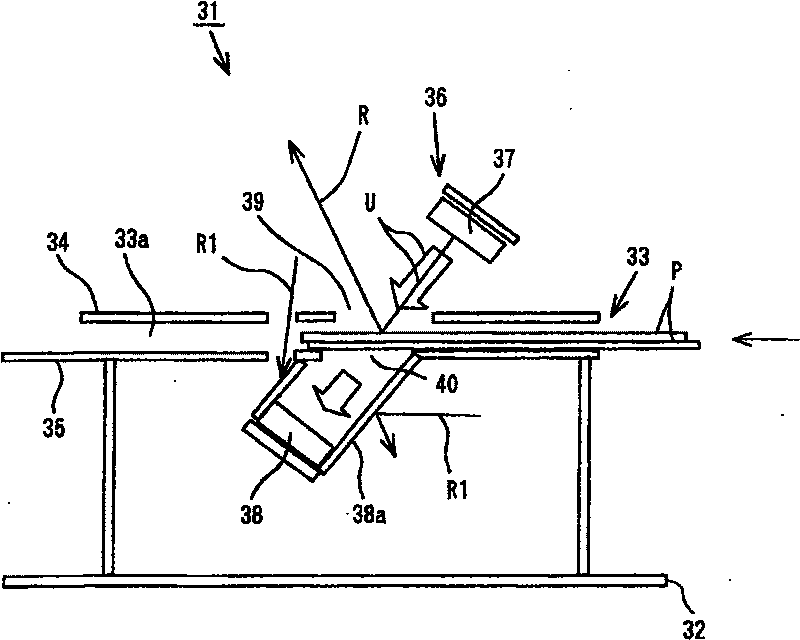

[0041] image 3 Shown is another embodiment of the paper overlapping conveyance detecting device 31. The copy paper overlapping conveying detecting device 31 is provided with a conveying path 33 on the upper side of the apparatus body 32 for conveying the paper P in a horizontal direction. The conveying path 33 is covered by two conveying guide plates 34, 35, which are an upper upper conveying guide plate 34 and a lower lower conveying guide plate 35, which are provided opposite to each other across a flat conveying space 33a.

[0042] In addition, the transmitter 37 of the ultrasonic sensor 36 is installed above the transmission path 33, and the receiver 38 of the ultrasonic sensor 36 is disposed below, so that the transmitter 37 and the receiver 38 face each other with the transmission path 33 therebetween. The above-mentioned ultrasonic sensor 36 sets the transmitting and receiving directions at a certain tilt angle, and adopts a configuration suitable for transmitting and rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com