Magnetic drive pump

A magnetic pump and magnetic drive technology, applied in the field of magnetic pumps, can solve the problems of difficult disassembly of threaded parts, consuming man-hours, increasing costs, etc., and achieving the effects of convenient disassembly, cost saving and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

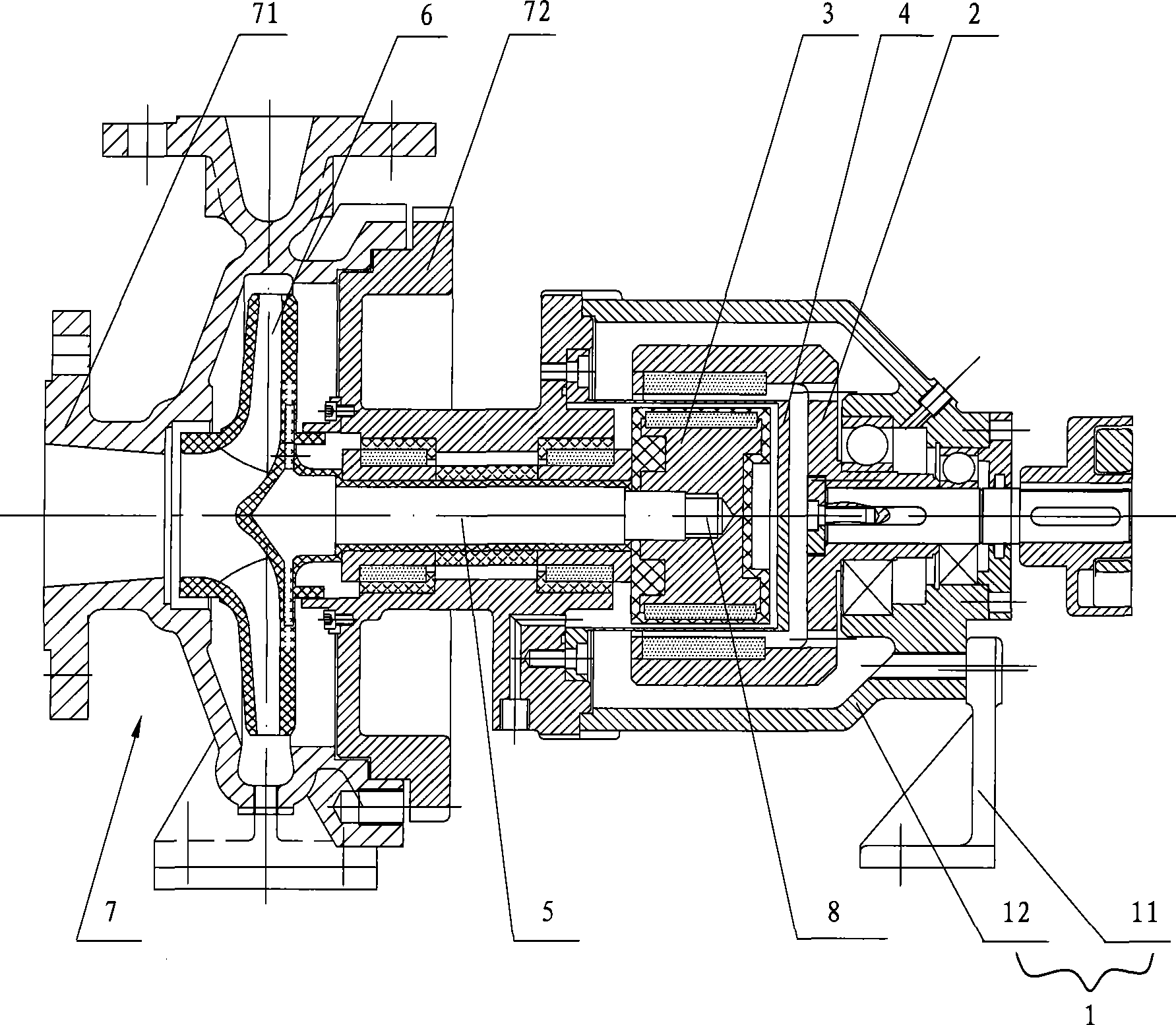

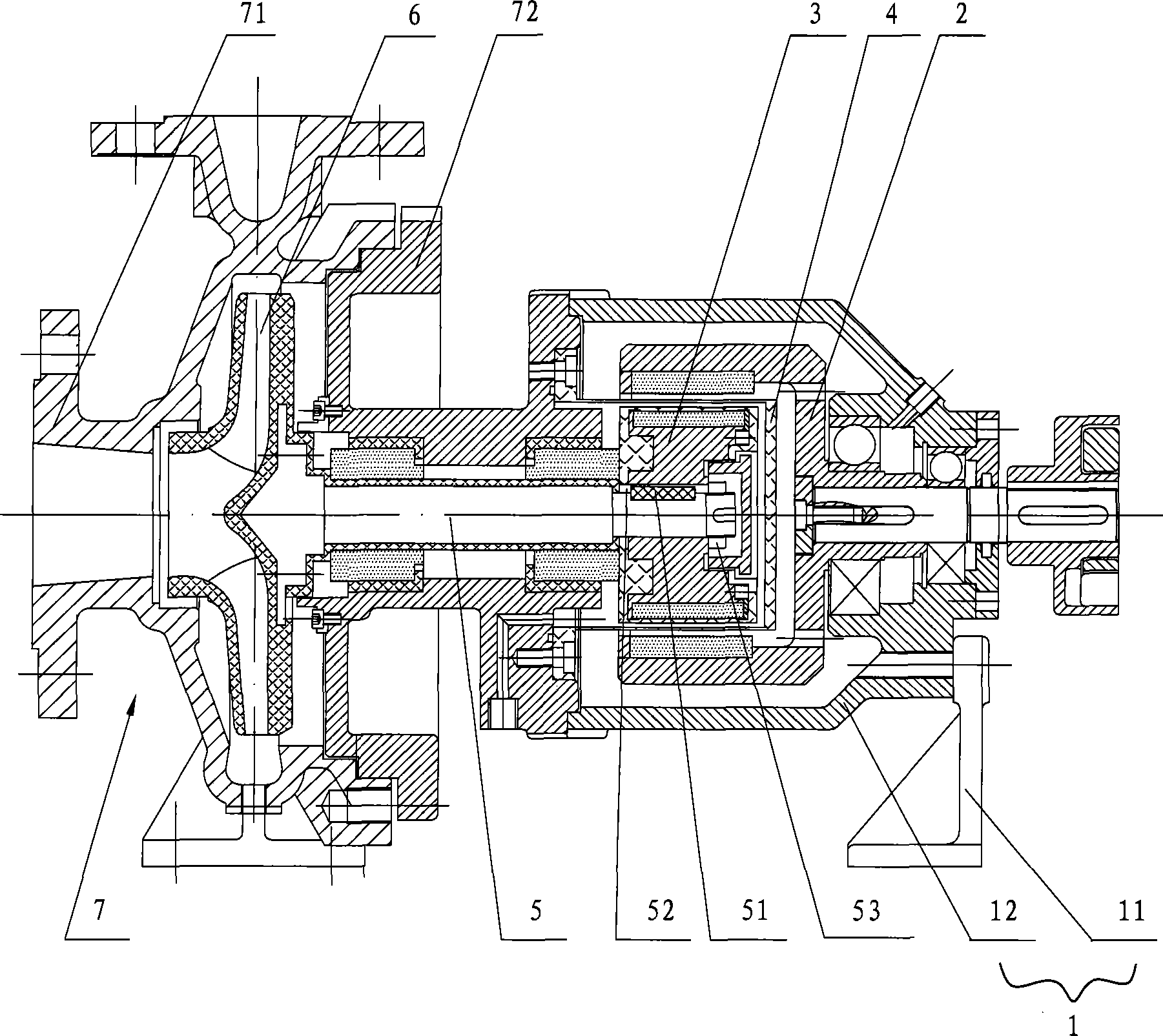

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0015] as attached figure 2 As shown, the magnetic pump implemented according to the present invention includes a bracket 1 composed of a bracket 11 and a suspension 12 fixedly installed on the bracket 11, an outer magnetic steel 2 directly connected with the motor and driven by the motor, and The inner magnetic steel 3 arranged concentrically with the outer magnetic steel 2, the spacer sleeve 4 arranged between the outer magnetic steel 2 and the inner magnetic steel 3, the pump shaft 5 connected with the inner magnetic steel 3 at one end, and the pump shaft 5 installed on the pump shaft The impeller 6 , the pump casing 7 located outside the pump shaft 5 and fixedly connected with the bracket 1 , the sliding bearing 8 and the thrust bearing 9 arranged concentrically with the pump shaft 5 . Wherein, the outer magnet 2 drives the inner magnet 3 to rotate throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap