Method for testing imbibition ability of water-loss reducer

A test method and water-retaining agent technology, applied in the direction of weighing by removing certain components, can solve problems such as large differences, no consideration of particle size gradation, and great differences in particle size gradation combinations of water-retaining agents. To achieve the effect of eliminating the influence of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

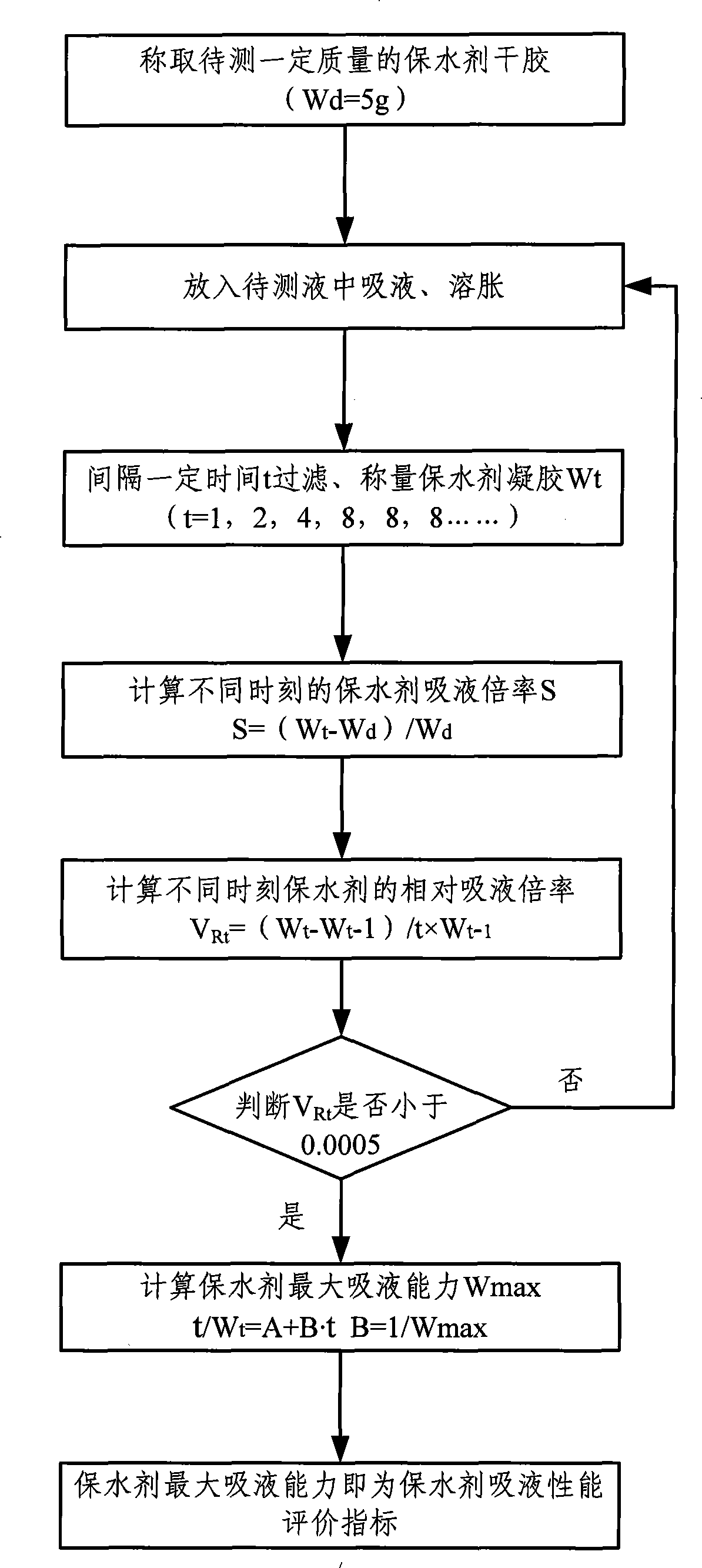

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0017] The bag filter method (including nylon bag, Dacron cloth, gauze, etc.) is relatively poor in data reproducibility and reliability because the part that acts as a filter is easily affected by the operation method and personal habits. The sieve method is more suitable because the shape of the sieve is fixed, and the area of the bottom of the sieve that acts as a filter is fixed, and it is not easily affected by human operation factors. Considering the swelling and dissolution process of the water-retaining agent during water absorption, it is most appropriate to use a 100mesh sieve, and this test also uses the 100mesh sieve filtration method.

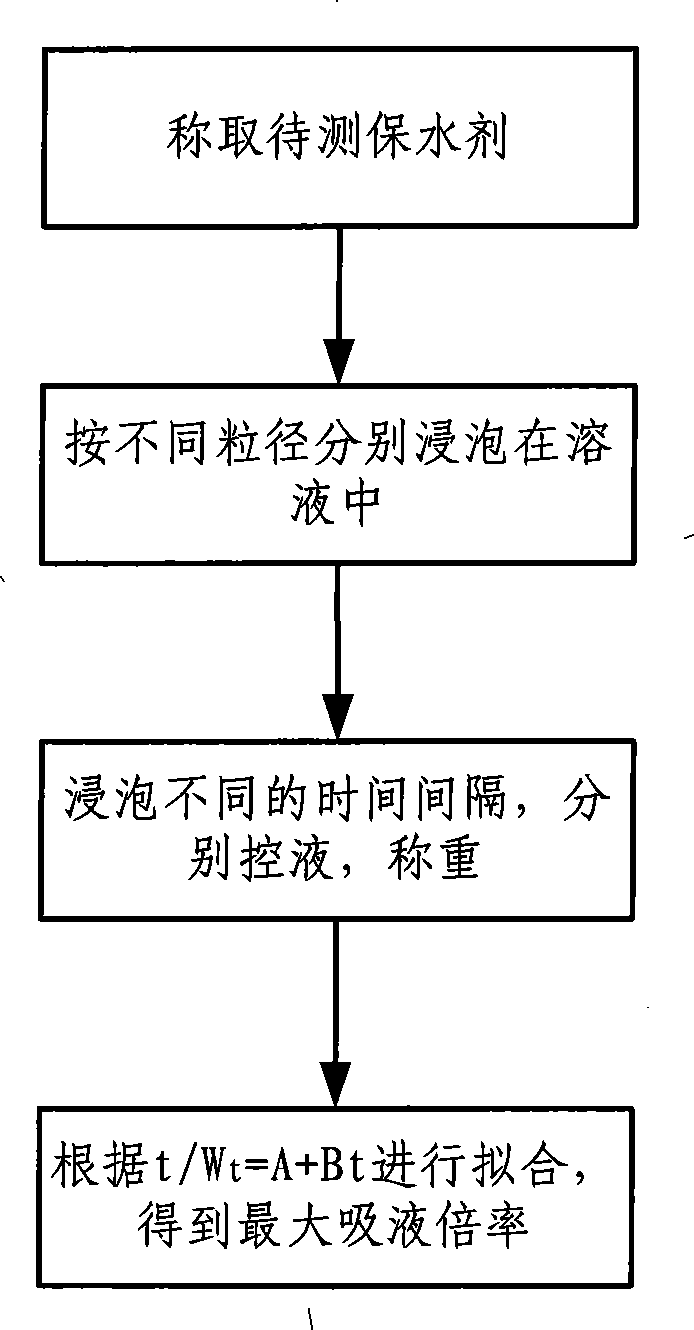

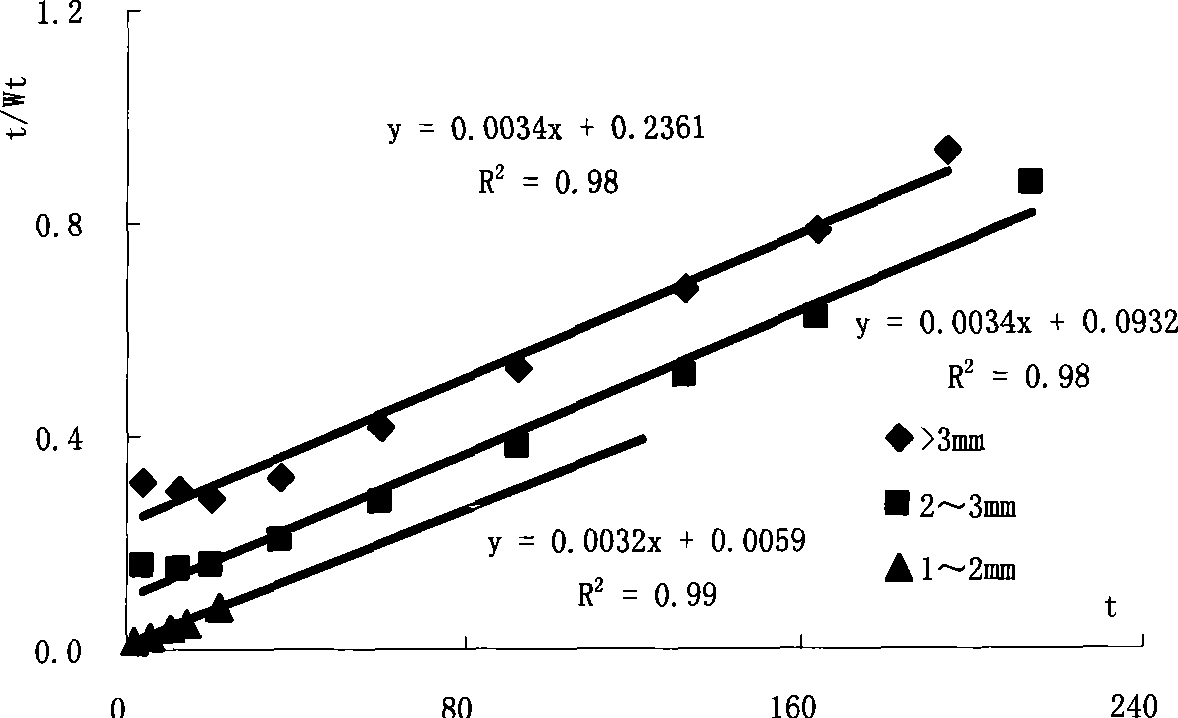

[0018] figure 1 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com