Lifting device for shift carrying

A lifting device and transfer technology, applied in the direction of lifting device, lifting frame, transportation and packaging, etc., can solve the problems of shortening the installation or moving construction period, time-consuming, inability to adjust the direction and the micro-adjustment of the up and down direction, etc., to shorten the installation or the effect of the relocation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The present invention is not limited to the forms shown in the drawings, but includes all implementations that satisfy the conditions described in the protection scope of the patent application.

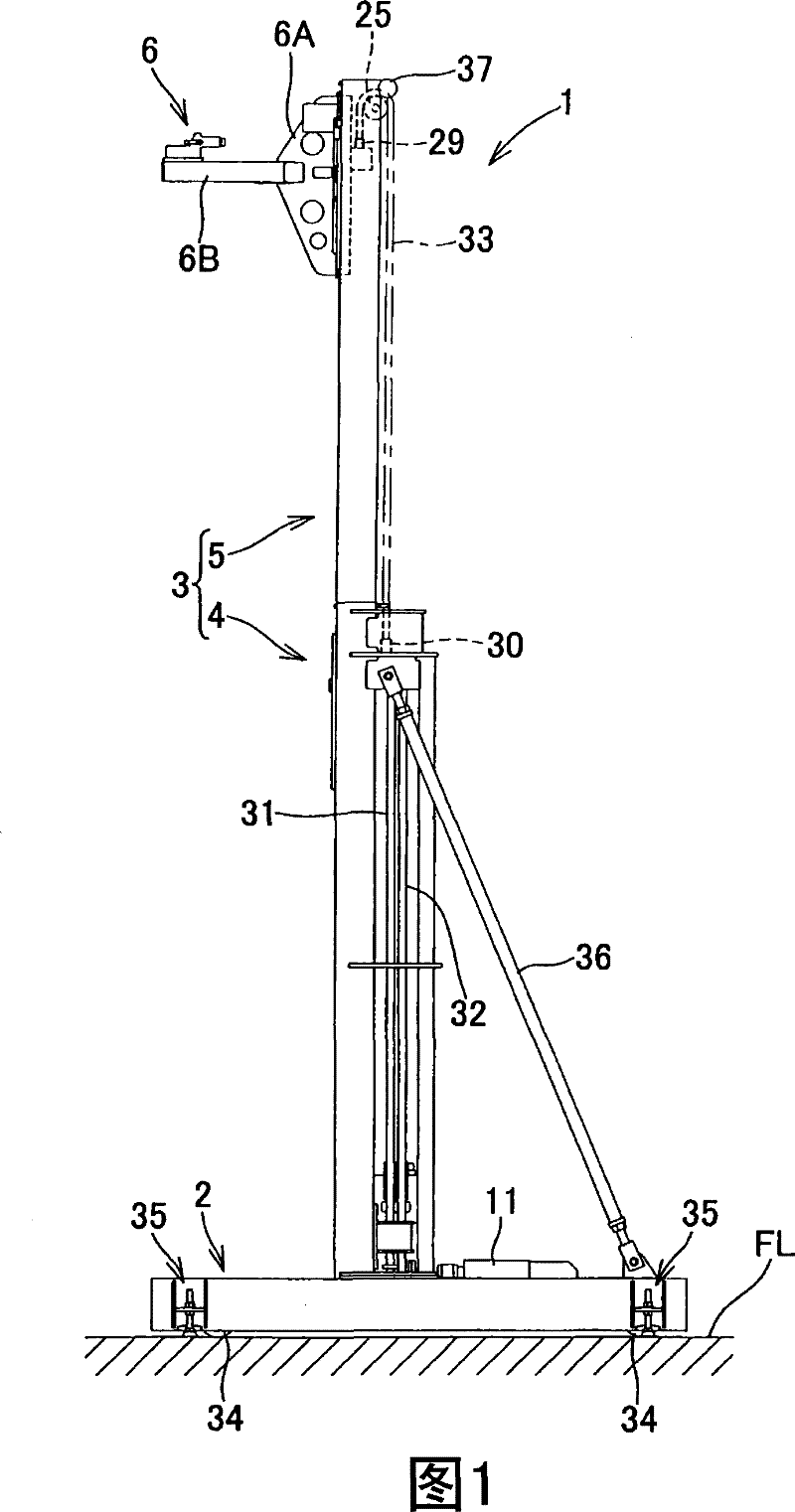

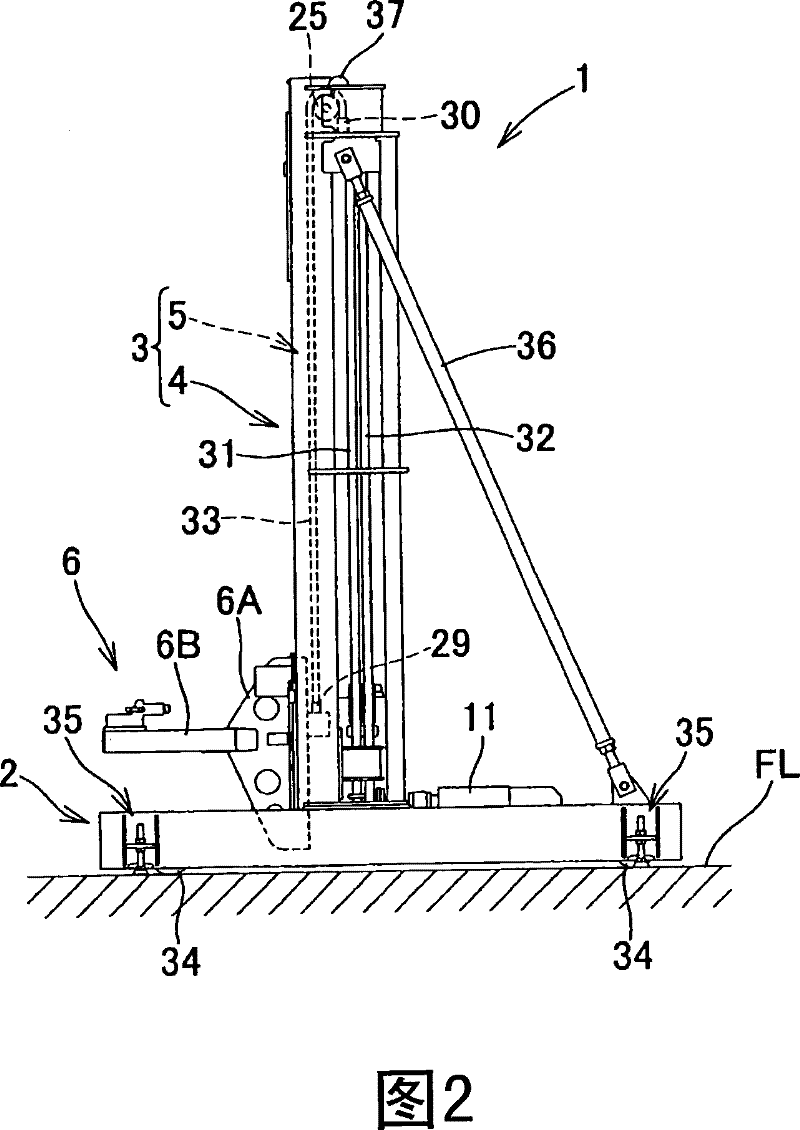

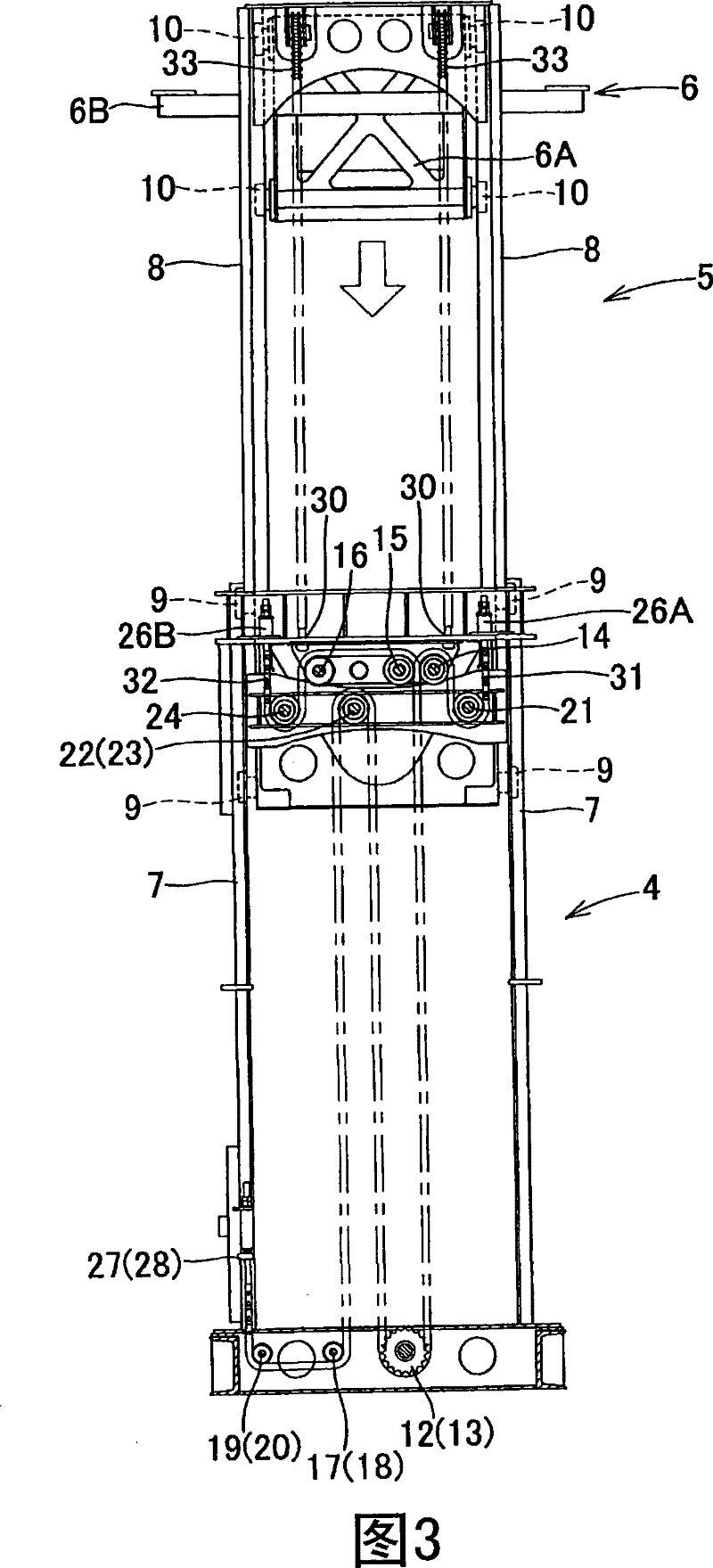

[0029] In addition, in this specification, the direction in which the support arm 6B extends from the bracket 6A of the workpiece supporting tool 6 is referred to as the front, and the left and right facing forward are referred to as the left and right. figure 1 and figure 2 It is a left side view showing the transfer elevating device 1 according to the embodiment of the present invention, figure 1 Indicates that the lifting column 5 is in a high position state, figure 2 It shows the state that the elevating column 5 is in the low position. image 3 and Figure 4 is a partially cutaway rear view for illustration of the chain linkage mechanism, image 3 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com